Top 2025 Hydraulic Gas Pump Trends and Innovations You Need to Know

As the demand for efficient and sustainable energy solutions continues to rise, the hydraulic gas pump industry is poised for significant advancements and innovations in 2025. These machines, integral to various applications including energy production, construction, and industrial processes, are evolving rapidly to meet the changing needs of the market. The upcoming trends highlight the importance of enhancing performance, reducing environmental impact, and increasing automation to streamline operations.

In this landscape, technologies that improve energy efficiency and offer innovative features are leading the charge. New materials and design techniques are being explored to enhance the resilience and reliability of hydraulic gas pumps, ensuring they can handle more demanding applications while consuming less energy. Furthermore, the integration of digital technologies is paving the way for smarter pumps that can provide real-time monitoring and diagnostics, informing users about maintenance needs and optimizing performance. With these trends on the horizon, stakeholders in the hydraulic gas pump sector must stay informed to leverage these innovations and maintain a competitive edge in an evolving market.

Emerging Technologies in Hydraulic Gas Pumps for 2025

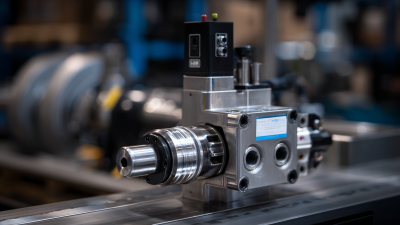

The hydraulic gas pump industry is poised for a significant transformation in 2025, driven by the emergence of innovative technologies that enhance performance and sustainability. One of the key trends is the integration of IoT (Internet of Things) capabilities, which allows for real-time monitoring and remote management of pump systems. This advancement not only boosts efficiency but also aids in predictive maintenance, reducing downtime and operational costs.

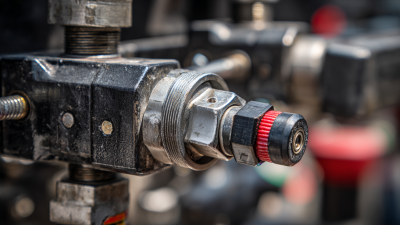

Another notable innovation is the use of advanced materials and smart design engineering. These developments result in lighter, more durable pumps that can operate at higher pressures while minimizing energy consumption. Furthermore, the push for sustainability has led to the exploration of eco-friendly hydraulic fluids, which mitigate environmental impacts without compromising performance.

Tips: When considering upgrades or replacements for hydraulic gas pumps, always assess the compatibility of newly emerging technologies with your existing systems. Incorporating IoT sensors, for example, can enhance data collection for improved operational insights. Additionally, regularly reviewing material advancements can help ensure you're using the most efficient and sustainable options available, ultimately prolonging the lifespan and effectiveness of your equipment.

Sustainability Trends Influencing Hydraulic Gas Pump Design

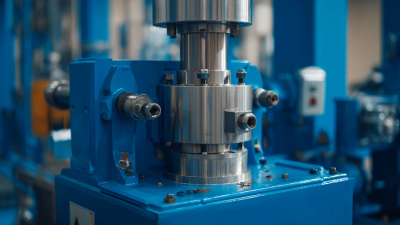

As the hydraulic gas pump industry evolves, sustainability trends play a pivotal role in shaping the design and functionality of these essential tools. According to a recent report by Grand View Research, the global hydraulic fluid market is projected to reach $23.49 billion by 2025, influenced heavily by the push for environmentally friendly alternatives. Manufacturers are increasingly focusing on bio-based hydraulic fluids that reduce ecological impact while enhancing pump performance. This shift not only addresses regulatory requirements but also meets the growing demand from consumers and industries prioritizing sustainable practices.

Furthermore, innovations in pump design are incorporating energy-efficient technologies that minimize resource consumption. The International Energy Agency has indicated that pumping systems account for approximately 20% of global electricity usage within the industrial sector. By implementing advanced materials and smart engineering solutions, companies are developing hydraulic gas pumps that exhibit lower energy losses and higher efficiencies. These innovations contribute to a significant reduction in carbon footprints, aligning with global goals for sustainable development. As organizations increasingly adopt sustainability metrics in their operational strategies, the embrace of such technologies will likely define the competitive landscape for hydraulic gas pumps in the years to come.

Top 2025 Hydraulic Gas Pump Trends and Innovations

Advancements in Automation and Smart Features for Pump Efficiency

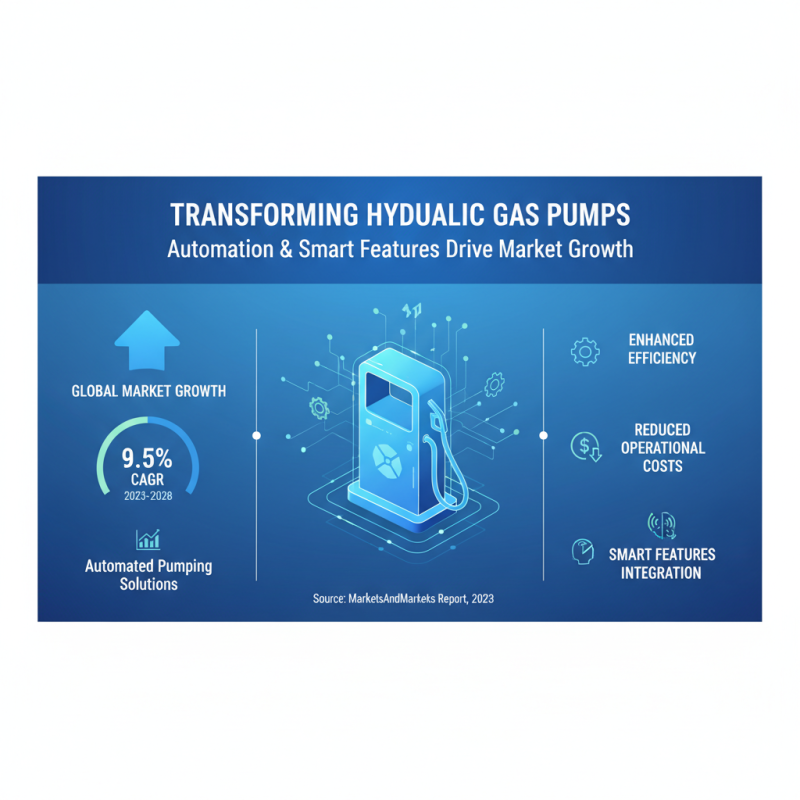

The landscape of hydraulic gas pumps is undergoing significant transformation as advancements in automation and smart features are increasingly integrated into their operations. According to a recent report by MarketsandMarkets, the global market for automated pumping solutions is expected to grow at a compound annual growth rate (CAGR) of 9.5% from 2023 to 2028. This growth is primarily driven by the demand for enhanced efficiency and reduced operational costs in various industrial sectors.

One of the most notable trends in the industry is the incorporation of IoT (Internet of Things) technology, providing real-time data monitoring and analytics. By leveraging advanced sensors and cloud connectivity, operators can now monitor pump performance and diagnose issues remotely, thereby minimizing downtime and maintenance costs. A study by Frost & Sullivan highlights that smart pumps can improve operational efficiency by up to 20% through predictive maintenance and optimized workflow processes.

Furthermore, the integration of machine learning algorithms is transforming the way hydraulic gas pumps function. These intelligent systems can analyze historical performance data to predict future operational parameters, enabling more efficient energy consumption and reducing wastage. In a survey conducted by the Hydraulic Institute, over 70% of industry professionals reported increased energy savings and overall efficiency due to the adoption of smart pumping technologies, affirming the critical role these innovations play in the evolution of hydraulic gas pumps.

Materials Innovation in Hydraulic Gas Pumps: Trends and Impact

The hydraulic gas pump industry is undergoing significant transformation due to innovations in materials that enhance performance, durability, and efficiency. A recent report from McKinsey & Company highlights that the use of advanced composites and lightweight alloys is driving a shift towards more efficient pumping systems, which can result in up to a 20% reduction in energy consumption. This not only addresses environmental concerns but also lowers operational costs for manufacturers and consumers alike.

Furthermore, the ongoing development of corrosion-resistant materials is crucial in extending the lifespan of hydraulic gas pumps. According to a study published by the Journal of Materials Science, the integration of polymers and high-strength steels has led to a 35% increase in resistance to corrosive agents commonly found in various hydraulic fluids. This innovation not only improves reliability in extreme conditions but also reduces maintenance downtime, thereby enhancing overall productivity. As we move towards 2025, the emphasis on sustainable, high-performance materials will play a pivotal role in shaping the future of hydraulic gas pump technology.

Market Demand and Future Projections for Hydraulic Gas Pumps

The demand for hydraulic gas pumps is expected to rise significantly in the coming years, driven by several key factors. One of the main drivers is the increasing need for efficient and reliable energy solutions in various industries, including construction, oil and gas, and manufacturing. As businesses aim to optimize their operations and reduce downtime, hydraulic gas pumps are becoming an essential component for effective fluid power systems. The trend is fueled by advancements in technology, which enhance the performance and efficiency of these pumps, leading to increased adoption across multiple sectors.

Future projections indicate that the market for hydraulic gas pumps will see substantial growth, with innovations likely to play a pivotal role. The integration of smart technologies, such as IoT and AI, is expected to revolutionize the way hydraulic systems operate. These technologies offer improved monitoring and predictive maintenance capabilities, leading to lower operational costs and increased reliability. Additionally, the focus on sustainability and environmental compliance is prompting manufacturers to develop more eco-friendly hydraulic gas pumps that minimize energy consumption and reduce emissions. As the market evolves, businesses will need to keep abreast of these innovations to stay competitive and meet the changing demands of their clients.

Top 2025 Hydraulic Gas Pump Trends and Innovations You Need to Know

| Trend/Innovation | Impact on Market | Future Projections (2025) | Market Demand (Units) |

|---|---|---|---|

| Integration of IoT | Enhanced monitoring and efficiency | 40% increase in smart device adoption | 150,000 |

| Energy Efficiency Improvements | Cost savings and environmental impact | Reduction of energy consumption by 30% | 200,000 |

| Adoption of Renewable Energy Sources | Shift towards sustainability | Increased utilization by 25% | 180,000 |

| Advanced Materials Development | Longer lifespan and better performance | Increase in material costs by 15% | 120,000 |

| Automation and Robotics | Labor cost reduction and precision | 20% growth in automated systems | 220,000 |

Related Posts

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

-

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025