5 Best Artificial Lift Pumps Revolutionizing Oil Recovery: Boost Efficiency and Cut Costs

The oil and gas industry is witnessing a transformative shift in production efficiency, primarily driven by advancements in artificial lift pump technology. According to a report by the International Energy Agency, artificial lift systems account for nearly 90% of oil production in conventional fields, significantly enhancing extraction processes. With global oil demand projected to reach 104 million barrels per day by 2026, optimizing production methods through state-of-the-art artificial lift pumps has become crucial for operators seeking to cut costs and maximize output. As the need for efficient and sustainable energy solutions intensifies, the latest innovations in artificial lift pump designs promise not only to boost efficiency but also to reduce operational expenses dramatically. In this article, we will explore the five best artificial lift pumps that are revolutionizing oil recovery, highlighting their key features and the profound impact they have on the industry.

Understanding Artificial Lift Pumps: Key Innovations in Oil Recovery

Artificial lift pumps are transforming the landscape of oil recovery, offering innovative solutions that enhance efficiency and reduce operational costs. These pumps play a critical role in extracting oil from wells that are unable to flow naturally due to formation pressure decline. Recent advancements in technology have led to the development of several key innovations, enabling operators to optimize production and extend the life of their wells.

One notable innovation is the introduction of electric submersible pumps (ESPs), which have improved performance and reliability. ESPs can handle a wide range of fluids and operate at significant depths, making them suitable for various oilfield conditions. Additionally, advancements in artificial intelligence and remote monitoring technologies allow for real-time performance assessments and predictive maintenance, minimizing downtime and maximizing output.

Another significant development is the use of gas lift systems, which utilize natural gas to enhance oil flow. By injecting gas into the production stream, these systems can effectively lower the fluid's density, allowing it to rise more easily to the surface. This method not only improves extraction rates but also reduces the energy required for pumping, resulting in lower operational costs and a smaller environmental footprint. Through these innovations, artificial lift pumps are leading the charge in modernizing oil recovery techniques and ensuring a more sustainable future for the industry.

Top 5 Artificial Lift Technologies Transforming Oil Fields Today

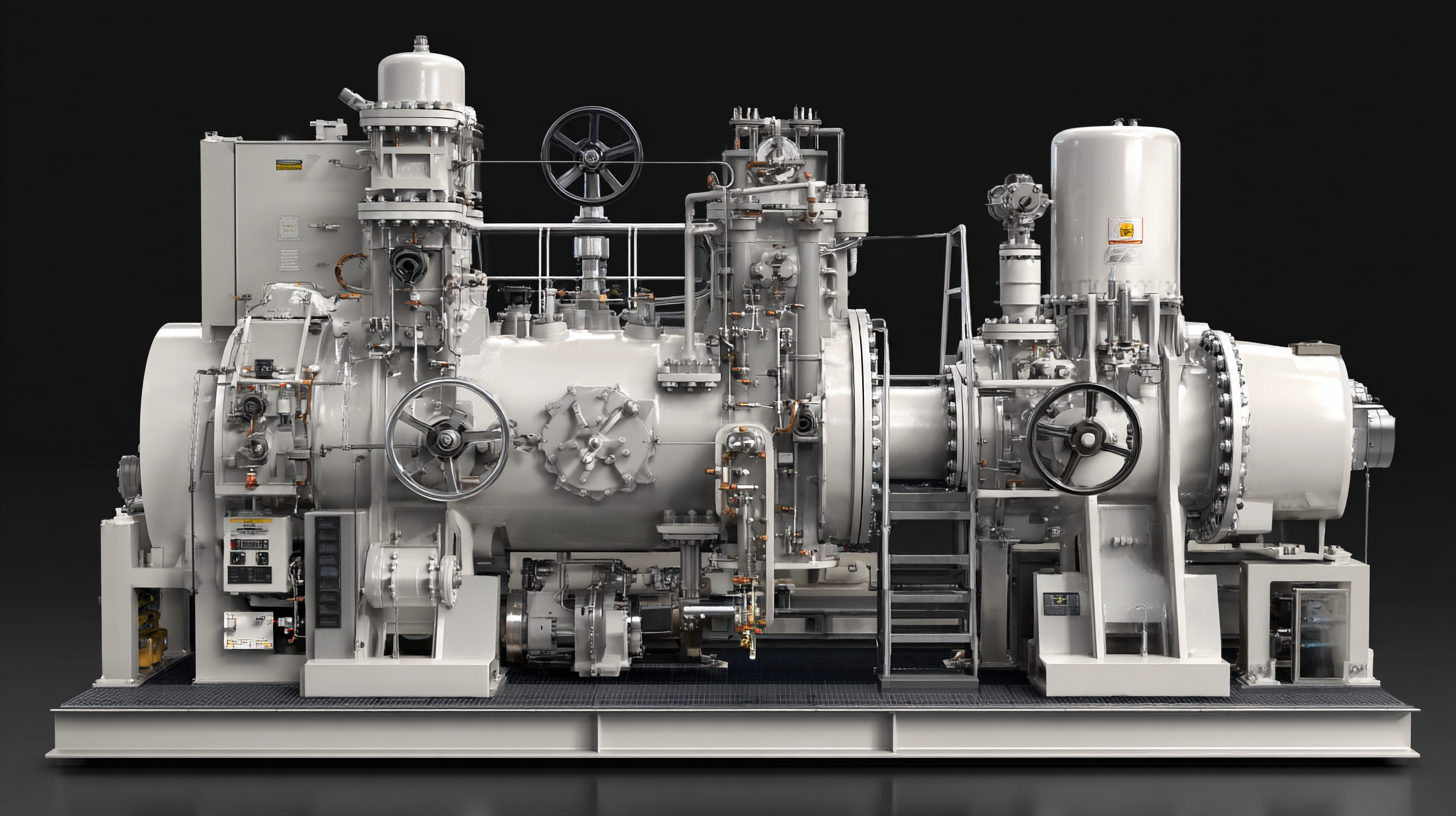

Artificial lift technologies are essential in enhancing oil recovery in modern oil fields. As hydrocarbon reservoirs age, natural pressure diminishes, necessitating the use of artificial lift systems to optimize production. Among the top technologies transforming oil production today, electric submersible pumps (ESPs) lead the charge with their ability to efficiently handle high flow rates and depths. These pumps are particularly effective in deep wells, significantly increasing output and ensuring a steady flow of oil.

Another innovative option is the rod lift system, which remains popular for its straightforward design and effectiveness in low to medium production rates. This traditional method is undergoing modernization, integrating smart technologies that monitor performance in real-time, allowing operators to optimize operations and reduce downtime. Additionally, progressive cavity pumps (PCPs) have gained attention for their versatility across various viscous fluids, making them ideal for unconventional reservoirs. Each of these technologies showcases how artificial lift systems are not only boosting efficiency but also driving down operational costs in today's competitive oil market.

Cost Savings and Efficiency Gains with Modern Artificial Lift Systems

Modern artificial lift systems are transforming oil recovery, fostering significant cost savings and efficiency gains. As oil producers face steep production declines and challenging environments, technologies like electric submersible pumps (ESPs) have become vital. Recent industry reports show that optimizing ESP operation can extend their lifetime by up to 30%, which translates to lower operational costs and minimized downtime.

To maximize the efficiency of artificial lifts, consider these tips:

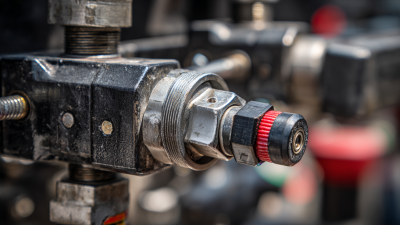

- Continuous Monitoring: Implement real-time monitoring systems to analyze pump performance and make data-driven adjustments to operating parameters, enhancing overall productivity.

- Invest in Technology: Upgrading to modern artificial lift technologies can yield substantial efficiency gains. For example, integrating advanced AI solutions can streamline operations and reduce costs by automating routine tasks and optimizing production schedules.

With the right strategies in place, companies can not only boost their oil recovery efficiency but also significantly cut operational costs, positioning themselves for success in a competitive market.

Comparative Analysis: Traditional vs. Advanced Artificial Lift Solutions

In the ever-evolving landscape of oil recovery, the choice between traditional and advanced artificial lift solutions plays a pivotal role in enhancing efficiency and reducing costs.

Traditional methods, such as rod pumps and gas lift, have been reliable over the decades, providing steady results in well production.

However, they often come with limitations, including high maintenance costs and reduced efficiency in challenging environments.

According to a 2022 market analysis by Grand View Research, traditional methods can lead to a production decline of up to 60% over a well's lifespan, necessitating the shift to more advanced technologies.

On the other hand, advanced solutions like electric submersible pumps (ESPs) and progressive cavity pumps (PCPs) have gained traction.

A report from the International Energy Agency highlights that ESPs can increase production rates by up to 30% compared to traditional pumps, particularly in deeper wells where pressure is substantial.

These modern systems often feature integrated controls and monitoring, which lead to reduced downtime and lower operational costs.

Tip: When considering an artificial lift system, evaluate the specific needs of your well.

For high-viscosity fluids, a PCP might be optimal, whereas ESPs excel in high-flow situations.

Choosing the right technology can significantly enhance production efficiency and overall profitability.

Future Trends in Artificial Lift Pumps and Their Impact on the Oil Industry

As the oil industry faces increasing pressure to enhance production efficiency and reduce operational costs, the evolution of artificial lift pumps presents a promising avenue for innovation. Emerging technologies in this field are poised to transform traditional practices, allowing for more effective management of well flows. For instance, advancements in smart pumping systems leverage data analytics and real-time monitoring to optimize performance, reduce downtime, and significantly improve extraction rates. These innovations are not only increasing the efficiency of oil recovery but are also leading to considerable cost savings for operators, making them more competitive in a fluctuating market.

Future trends suggest that the integration of renewable energy sources and automation will further revolutionize artificial lift methods. Solar-powered pumps and systems utilizing artificial intelligence are gaining traction, minimizing reliance on fossil fuel energy and enhancing sustainability. Furthermore, the move towards modular and scalable pump designs allows operators to easily adapt to varying production demands while maintaining minimal upfront investment. As the oil industry embraces these cutting-edge technologies, the landscape of oil recovery will undoubtedly shift, paving the way for a more efficient and environmentally-conscious future.

Related Posts

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

Ultimate Guide to Choosing the Right Oil Jet Pump for Your Industry Needs

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance