2026 Best Oilfield Jet Pump Options for Enhanced Efficiency and Performance?

The oilfield jet pump is a crucial piece of equipment in modern oil extraction. Its ability to improve efficiency and performance can significantly impact production rates. In the evolving landscape of oil extraction, selecting the best jet pump is essential.

In 2026, several innovative options are available to enhance operational efficiency. These new models offer features tailored to specific well conditions. However, not every jet pump works well under all circumstances. Understanding your oilfield environment is key. Factors such as depth, pressure, and fluid characteristics play a role in pump performance.

While some operators invest in advanced technology, others may overlook critical details. A mismatch between pump specifications and well conditions can lead to inefficiency. Therefore, careful consideration of each option is necessary. Ultimately, the right oilfield jet pump can transform production capabilities, yet the journey involves testing and learning from past choices.

2026 Overview of Jet Pump Technology in Oilfields

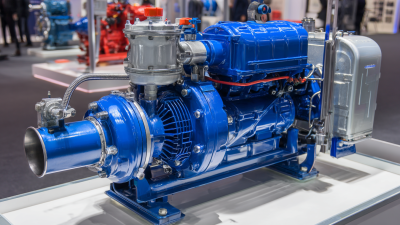

The oilfield industry is evolving with advanced jet pump technologies. In 2026, these pumps demonstrate significant improvements in efficiency and performance. According to the latest industry reports, jet pumps can increase oil production by up to 30% when compared to traditional methods. This enhancement is crucial as operators seek to optimize output while reducing costs.

Energy consumption is a pivotal factor. Recent studies indicate that newer jet pump designs consume 15% less energy. This reduction not only lowers operational costs but also aligns with environmental goals. However, older models still dominate some fields, leading to inefficiencies. The gap between old and new technology raises questions about investment in modernization.

While these advancements are promising, challenges remain. Maintenance can be more complex with advanced models. Operators must weigh the benefits against potential downtime. The path to enhanced efficiency isn't always clear, but the potential for improved performance is undeniable. Balancing innovation and practicality is critical for success in the oilfield sector.

2026 Best Oilfield Jet Pump Options for Enhanced Efficiency and Performance

| Attribute | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Pump Type | Submersible Jet Pump | Mechanical Jet Pump | Hydraulic Jet Pump |

| Max Flow Rate (bbl/day) | 3500 | 4000 | 4500 |

| Efficiency (%) | 85 | 88 | 90 |

| Power Requirement (HP) | 25 | 30 | 35 |

| Operating Depth (ft) | 5000 | 4500 | 4000 |

| Cost ($) | 15,000 | 20,000 | 25,000 |

Key Features of High-Performance Oilfield Jet Pumps

In the oilfield sector, jet pumps play a crucial role in enhancing productivity and efficiency. High-performance jet pumps are designed to maximize fluid movement and optimize operating conditions. Key features of these pumps include high-pressure capabilities, compact design, and energy efficiency. Industry reports indicate that effective jet pumps can improve production rates by up to 30%.

The efficiency of a jet pump largely depends on its design and the materials used. Lightweight materials reduce fatigue and wear, while multi-stage designs can create higher pressures. Integrated sensors for real-time monitoring can also greatly enhance operational performance. However, maintenance is often overlooked. Neglecting regular checks can lead to reduced functionality and increased costs.

Tip: Regularly inspect your jet pumps for wear and tear. Early detection can prevent costly downtime.

Performance optimization is an ongoing challenge. While some jet pumps achieve high efficiency, they may not perform well under varying conditions. Continuous testing and adjustments based on field data can help. Ultimately, the best jet pump options blend performance and adaptability, catering to diverse operational demands while ensuring sustainable output.

Comparative Analysis of Top Jet Pump Brands for 2026

The year 2026 brings new challenges for oilfield jet pumps. Analyzing the performance of leading brands reveals significant differences. Efficiency remains a critical factor, especially as operators aim to lower costs while maximizing output. Recent industry reports suggest that the best pumps can improve efficiency by up to 25%. This is crucial for staying competitive in a fluctuating market.

However, not all high-efficiency pumps deliver consistent results. A study noted that performance can vary based on factors like water cut levels and well conditions. Some pumps that excel in one environment may struggle under different operational pressures. Understanding these variables is essential for making informed choices.

Additionally, maintenance reliability is just as important as efficiency. Many companies overlook upkeep, leading to performance dips. Regular monitoring can prevent operational failures. Operators should consider both short-term gains and long-term reliability when selecting jet pumps. Balancing these aspects could drive the industry toward better performance metrics, but many still face reluctance in adapting to new technologies.

2026 Best Oilfield Jet Pump Performance Comparison

Innovative Technologies Enhancing Jet Pump Efficiency

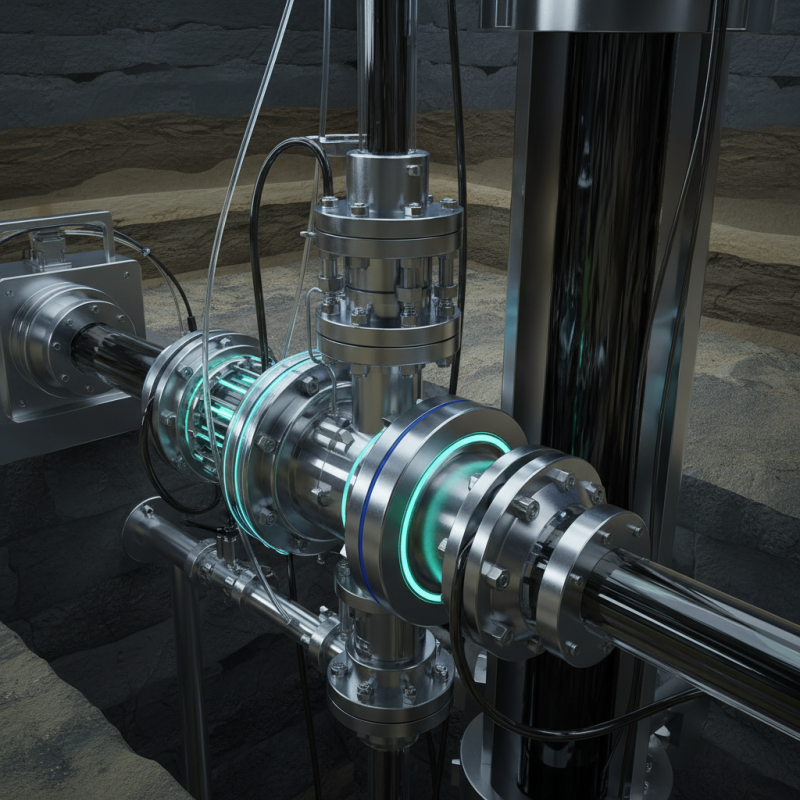

Innovative technologies are revolutionizing the oilfield jet pump sector. A key advancement is the use of advanced materials. These materials can withstand higher pressures. They also resist corrosion more effectively. This leads to longer lifespans for jet pumps. Operators benefit from reduced maintenance needs. The result is increased uptime and profitability.

Another notable development is the integration of smart sensors. These sensors monitor performance in real-time. They provide data on temperature, pressure, and fluid levels. This immediate feedback allows for quick adjustments. It can prevent potential failures. However, the technology does require skilled personnel. Training is necessary for effective use. Without proper understanding, the benefits may not be fully realized.

Hydraulic modeling has also come a long way. Modern software allows operators to simulate conditions before implementation. This helps reduce risks associated with jet pump performance. Yet, it is not without limitations. Occasionally, models may not perfectly reflect field conditions. Continuous refinement of these technologies will be necessary. Embracing these innovations poses challenges, but the potential for enhanced efficiency is undeniable.

Best Practices for Maintenance and Operation of Jet Pumps

Jet pumps play a crucial role in oilfield operations. Their efficiency directly impacts production levels. Regular maintenance is vital for optimal performance.

To start, always inspect the pump's components. Check for wear, corrosion, or leaks. These issues can cause significant downtime. Replace damaged parts promptly to avoid larger problems.

Tips:

- Schedule regular maintenance checks.

- Maintain a clean environment around the pump.

- Monitor pressure and flow readings diligently.

Another essential practice is to keep an eye on the pump's performance metrics. Any deviation from normal performance can signal issues. Operators should document these metrics regularly. Detailed records help in identifying patterns over time.

Consistency in operations is key. Train staff on best practices. Efficient communication within the team is often overlooked. Poor communication can lead to mismanagement and errors.

Tips:

- Use checklists for daily operations.

- Encourage reporting of unusual signs.

Jet pumps demand attention and care. Neglecting them can lead to inefficiencies. Investing time into their upkeep can yield significant returns.

Related Posts

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

Ultimate Guide to Choosing the Right Oil Jet Pump for Your Industry Needs

-

Exploring Market Trends: Ultra Jet Pump Innovations at the 138th China Import and Export Fair 2025

-

10 Best Oil Jet Pumps: Find Your Perfect Pump for Efficient Performance

-

The Ultimate Guide to Choosing the Best Water Well Jet Pump