2026 How to Choose the Right Surface Jet Pump for Your Needs?

Selecting the right surface jet pump is crucial for optimal performance. According to industry expert John Smith, “The effectiveness of a surface jet pump hinges on understanding your specific needs.” The landscape of surface jet pumps is diverse, featuring various designs and capabilities. Different applications can demand specific features, such as flow rate, horsepower, or suction depth.

For someone unfamiliar with surface jet pumps, the options may seem overwhelming. Each type serves unique purposes. Some pumps excel in residential applications, while others are built for commercial use. It's essential to assess factors like the water source and required pressure to avoid costly mistakes. A poorly chosen pump may lead to inefficiency and unnecessary expenses.

One might assume they know what they need until they face the actual installation. The nuances of each pump design can reveal gaps in understanding. Even seasoned professionals occasionally overlook critical specifications. Failing to consider these elements can result in frustration. When navigating this selection process, patience and research are essential for making an informed choice.

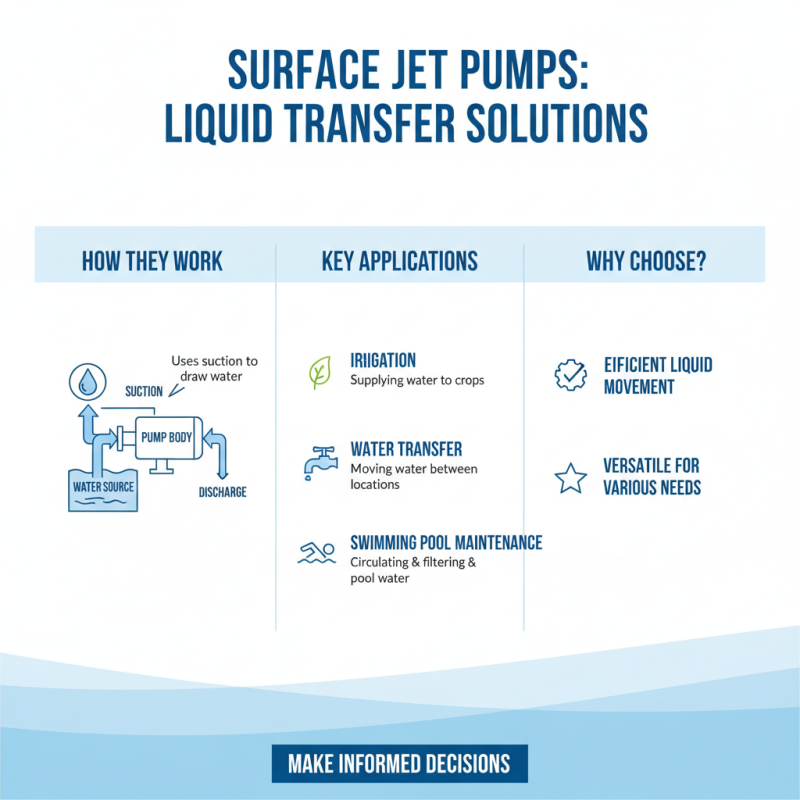

Understanding Surface Jet Pumps and Their Applications

Surface jet pumps are vital in various applications including irrigation, water transfer, and even swimming pool maintenance. They work by using suction to draw water into the pump, making them efficient for moving liquids. Understanding their specific uses will help you make informed decisions when selecting the right pump for your needs.

When selecting a surface jet pump, consider the water source and distance. If you need to pump water from a deep well, the pump must be powerful enough to reach it. Evaluate the flow rate requirements as well. Different applications have varying needs. For instance, an irrigation system often needs a higher flow rate than a residential fountain.

**Tips:** Always check the pump's specifications. Ensure it matches your application requirements. Don't hesitate to reach out for advice. Sometimes, the best choices aren't the most expensive ones. Reflect on past experiences; they often highlight areas for improvement in your selection process. Making informed choices will save time and resources.

Key Factors to Consider When Choosing a Surface Jet Pump

When selecting a surface jet pump, several key factors should be taken into account. The pump's intended application plays a crucial role. Different uses require varying flow rates and pressures. For example, irrigation may need higher flow rates, while a fountain might prioritize aesthetics over volume. Understanding these requirements allows for better decision-making.

Power consumption is another important consideration. It directly impacts operational costs. According to a 2022 industry report, inefficient pumps can waste up to 30% more energy compared to standard models. This increases expenses over time and creates a larger carbon footprint. Consumers should compare energy ratings carefully.

Tips: Assess your water source and demand accurately. This step is vital. A mismatch can lead to inefficiencies. Additionally, consider maintenance needs. Ignoring this aspect can lead to unexpected repairs and downtime. Lastly, ensure compatibility with existing systems. Incompatibilities often surface late in the process, leading to extra costs and headaches.

2026 How to Choose the Right Surface Jet Pump for Your Needs? - Key Factors to Consider When Choosing a Surface Jet Pump

| Factor | Description | Considerations |

|---|---|---|

| Flow Rate | The volume of water the pump can move, typically measured in gallons per minute (GPM). | Determine the required flow rate based on your system’s needs. |

| Head Height | The maximum height the pump can lift water. | Assess the vertical distance water must be lifted in your system. |

| Power Source | The type of energy needed to operate the pump (electric, gas, etc.). | Ensure availability of the power source in your setup. |

| Material | The construction material of the pump components (e.g., stainless steel, plastic). | Choose materials that match the water conditions to avoid corrosion. |

| Cost | The initial purchase price and ongoing maintenance costs. | Balance budget constraints with required features. |

| Noise Level | The sound produced by the pump during operation. | Consider noise restrictions based on installation location. |

Evaluating Pump Specifications: Flow Rate and Pressure Requirements

Choosing the right surface jet pump begins with understanding your requirements. The flow rate is crucial. This determines how much water the pump can move in a given time. It's essential to know your system's needs. For example, a small garden fountain demands much less than an irrigation system.

Pressure requirements are equally important. A pump must generate enough pressure to overcome elevation changes. If your water source is deep, this becomes vital. Evaluate the height your water needs to rise. A mismatch in pressure can lead to inefficiencies.

Tips: Check specifications carefully. Look for pumps that meet your flow rate and pressure needs. Don’t rush your decision. A common mistake is choosing a pump that's too powerful or too weak. Consider what you really need before purchasing.

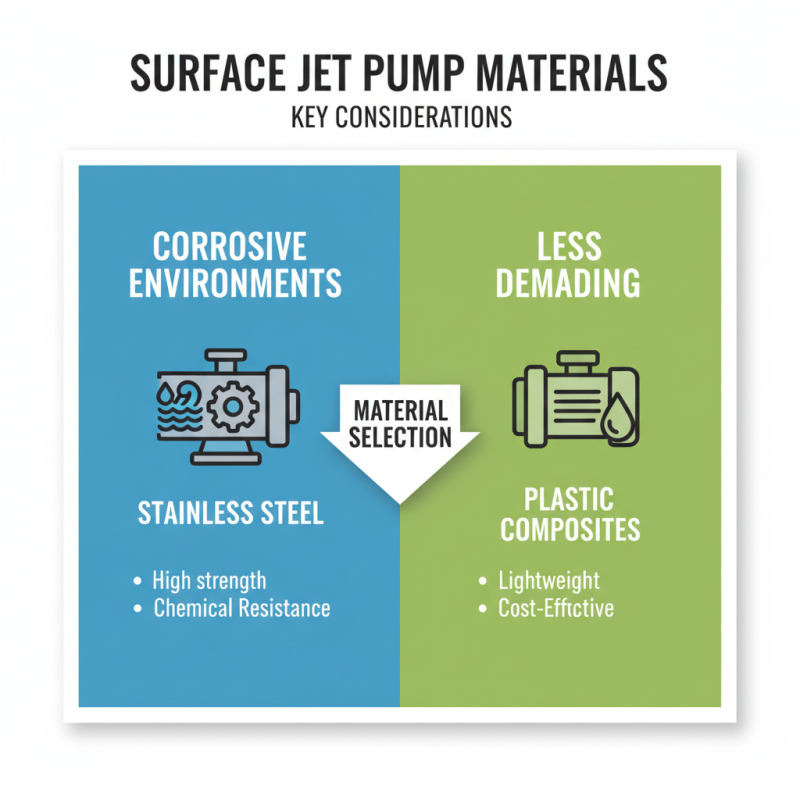

Assessing Material Compatibility and Environmental Conditions

Choosing the right surface jet pump involves careful consideration of material compatibility and environmental conditions. Many materials can react differently under various conditions. For example, materials like stainless steel may perform well in corrosive environments, while plastic may be better suited for less demanding situations.

The chemical resistance of pump materials is crucial. A report from the Fluid Engineering Institute indicates that 70% of pump failures are due to material incompatibility. Selecting materials that can withstand specific chemicals is vital. Common environments include acidic, alkaline, and saline conditions, all of which can impact pump longevity and efficiency.

Temperature and pressure also play significant roles. High temperatures can weaken some materials. Pressure fluctuations may lead to leaks or failures. Each application has unique demands, and a mismatch can result in costly downtime. Thoroughly assessing environmental conditions can make a significant difference in pump performance and reliability.

Maintenance and Cost Considerations for Surface Jet Pumps

When considering surface jet pumps, maintenance plays a crucial role in overall efficiency and longevity. A recent industry report indicates that regular maintenance can increase a pump’s lifespan by up to 30%. Simple checks, such as inspecting sealing and connections, are necessary. Ensuring that no debris clogs the impeller is key. Even minor neglect can lead to severe breakdowns.

Cost considerations also significantly impact long-term ownership. The initial purchase price may only represent a fraction of total expenses. A study suggested that operational costs can be as high as 60% over the pump’s lifetime. This includes energy consumption, spare parts, and labor. Operating in optimal conditions is essential for keeping these costs low. Monitoring how often the pump runs has a direct link to energy efficiency.

End-users often overlook the importance of choosing the right materials tailored to specific environments. For example, pumps in corrosive environments need particular attention. The material selection can either reduce maintenance needs or increase them. Too often, users compromise between cost and quality, which can lead to regrettable choices. Regular evaluation of pump performance against expectations helps identify these mistakes early.

Related Posts

-

5 Essential Tips for Choosing the Right Surface Jet Pump for Your Needs

-

Exploring Market Trends: Ultra Jet Pumps at the 138th Canton Fair 2025 in China

-

Exploring Market Trends: Ultra Jet Pump Innovations at the 138th China Import and Export Fair 2025

-

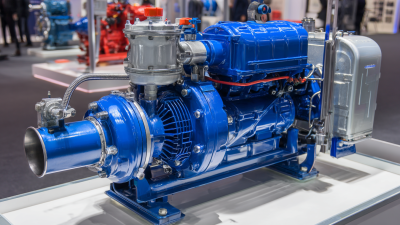

Why Choose Ultra Jet Pumps for Your Water Needs and What Are Their Benefits

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps