How to Choose the Right Gas Well Pump for Your Needs in 2025

In 2025, selecting the right gas well pump is more crucial than ever as the energy landscape continues to evolve. The efficiency and effectiveness of gas extraction largely depend on the type of pump chosen, making it essential for operators to carefully consider their specific requirements. Factors such as well depth, gas composition, and production rates play a pivotal role in determining the most suitable gas well pump. Understanding these variables will enable operators to make informed decisions that not only enhance productivity but also optimize operational costs.

As technological advancements continue to reshape the gas extraction industry, it is important to stay abreast of the latest innovations in gas well pumps. From improved materials that withstand harsh environments to cutting-edge designs that maximize flow rates, the market is replete with options that cater to diverse needs. By gaining insights into the characteristics and functionalities of various pumps, operators can better align their choices with the demands of their wells, ensuring reliable and efficient operation. Whether you're a seasoned professional or new to the industry, mastering the art of selecting the right gas well pump can significantly impact overall success in gas production.

Factors to Consider When Selecting a Gas Well Pump in 2025

When selecting a gas well pump in 2025, several critical factors play a significant role in ensuring optimal performance and efficiency. First and foremost, understanding the specific requirements of your well is paramount. According to the Gas Processors Association, the average gas production rate has shown an increase of 2.5% annually over the past five years, which necessitates the use of pumps that can handle high-pressure environments while maintaining reliability. Assessing the well's depth, pressure, and production volume is crucial, as these elements will dictate the type and capacity of the pump needed.

Moreover, it's essential to consider the type of gas being extracted. The Natural Gas Supply Association reports that the composition of gas—ranging from sweet to sour gas—can significantly influence the selection of materials and pump design. For instance, sour gas may require pumps constructed from corrosion-resistant materials to withstand sulfur and other contaminants. In addition, energy efficiency must be a factor in your decision-making process. Research from the American Gas Association indicates that efficiencies of well pumps can vary significantly and choosing a pump with higher operational efficiency can lead to cost savings and reduced environmental impact in the long run. Balancing these factors is key to making an informed decision that aligns with operational goals and regulatory considerations.

Types of Gas Well Pumps Available and Their Applications

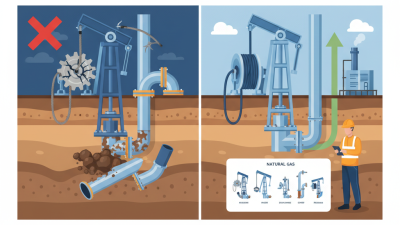

When selecting the right gas well pump for your needs, it’s essential to explore the various types available and their specific applications. Gas well pumps can be broadly categorized into reciprocating pumps, progressive cavity pumps, and pneumatic pumps. Reciprocating pumps are known for their high efficiency and ability to handle viscous fluids, making them ideal for wells with heavy gas and liquid production. Progressive cavity pumps, on the other hand, provide a continuous flow and are excellent for low to medium viscosity fluids. Pneumatic pumps excel in environments where electrical hazards are a concern, utilizing compressed air to function effectively.

Tips for choosing the right pump include evaluating the viscosity of the fluids being extracted and the required flow rates. Prioritize pumps designed to operate efficiently within your specific conditions, as this can significantly reduce operational costs and downtime. Additionally, consider the pump's maintenance needs and overall reliability for long-term operation.

Another important factor is the environment in which the pump will operate. If your well is situated in a remote location, durability and ruggedness become paramount. Assessing the local climate and terrain can help you select a pump that will withstand challenging conditions while maximizing output. Always consult with experts to determine the best fit for your specific requirements.

Types of Gas Well Pumps and Their Applications (2025)

This chart illustrates the efficiency of various types of gas well pumps. Each type serves different applications depending on the specific needs of the gas well operation, with centrifugal and submersible pumps demonstrating higher efficiencies in typical scenarios.

Understanding Pump Specifications and Performance Metrics

When selecting a gas well pump, understanding pump specifications and performance metrics is crucial for optimizing production efficiency. Key specifications include flow rate, discharge pressure, and horsepower requirements. Flow rate, typically measured in gallons per minute (GPM), is instrumental in determining a pump's capacity to move gas. According to a 2023 report by the International Association of Oil & Gas Producers, the average flow rate for efficient gas well pumps ranges from 15 to 200 GPM depending on the well conditions and environmental factors.

Discharge pressure is another critical metric, as it indicates the pump's ability to overcome system resistance and transport gas to the surface and beyond. For instance, operational pressures often vary between 500 to 3,000 PSI across different well environments. Understanding the specific discharge pressure requirements for your gas well can significantly affect the pump’s performance and durability. Additionally, horsepower requirements must align with the selected pump’s specifications to ensure optimal operational efficiency. According to a study by the Society of Petroleum Engineers, improper horsepower selection can lead to a 10% decrease in energy efficiency, translating to increased costs and reduced output. By thoroughly analyzing these metrics, operators can select a gas well pump that meets their unique operational demands.

How to Choose the Right Gas Well Pump for Your Needs in 2025

| Pump Type | Flow Rate (GPM) | Max Head (ft) | Power Requirement (HP) | Efficiency (%) | Typical Applications |

|---|---|---|---|---|---|

| Diaphragm Pump | 10 - 100 | 50 | 2 - 10 | 75 | Low flow applications, chemical transfer |

| Centrifugal Pump | 50 - 1000 | 150 | 10 - 50 | 85 | High flow applications, quality water supply |

| Submersible Pump | 20 - 500 | 300 | 5 - 20 | 78 | Drainage, dewatering, wastewater |

| Gear Pump | 5 - 200 | 100 | 1 - 15 | 80 | Viscous fluids, fuel transfer |

| Progressive Cavity Pump | 10 - 300 | 200 | 3 - 25 | 85 | Slurries, wastewater treatment |

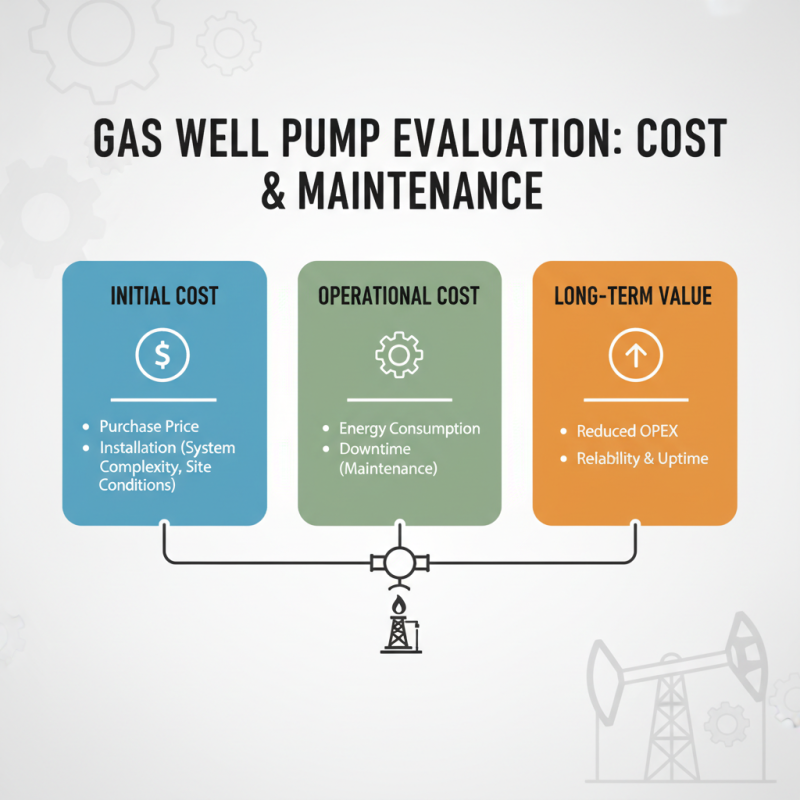

Evaluating the Cost and Maintenance Requirements of Gas Well Pumps

When evaluating gas well pumps, cost and maintenance requirements should be at the forefront of your decision-making process. The initial purchase price of the pump is just one aspect; you should also consider the installation costs, which can vary depending on the complexity of the system and the site conditions. Additionally, ensure you factor in the long-term operational costs, including energy consumption and potential downtime due to maintenance.

Maintenance is crucial for the efficiency and longevity of your gas well pump. Regular inspections and servicing can help identify potential issues before they escalate, saving you from costly repairs. Consider creating a maintenance schedule that includes checking seals, lubricating components, and ensuring all electronic systems are functioning properly.

**Tips:** Always consult with a professional for installation to avoid common pitfalls that lead to increased maintenance costs. Additionally, investing in high-quality components, even if they come at a higher upfront cost, can result in significant savings over the pump's lifespan due to reduced maintenance needs. Lastly, familiarize yourself with the expected lifespan of each type of pump, as this will help you make informed decisions regarding your budget and maintenance planning.

Future Trends in Gas Well Pump Technology for Enhanced Efficiency

As we look ahead to 2025, the advancements in

gas well pump technology are poised to significantly enhance operational efficiency in the energy sector.

One of the key trends is the increased integration of automation and remote monitoring systems.

These innovations allow operators to collect real-time data on pump performance, fluid dynamics, and reservoir conditions,

enabling more informed decision-making. Automated systems can optimize pump operation,

reducing energy consumption and minimizing downtime by predicting maintenance needs before they become critical.

Additionally, materials science is playing a crucial role in the evolution of gas well pumps.

The development of more durable, corrosion-resistant materials can lead to pumps that endure harsher environments

and longer operational lifespans. This not only extends the life of the equipment but also ensures consistent performance, which is vital for

maintaining productivity in gas extraction. Moreover, these advancements often come hand-in-hand with designs that reduce friction, further enhancing the

efficiency of gas transport and extraction processes. As these trends converge,

operators will have more tools at their disposal to maximize output while minimizing environmental impact.

Related Posts

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry

-

Why Do Gas Well Pumps Fail and How to Ensure Your Pump's Longevity?

-

Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

10 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

-

How to Choose the Right Water Well Pressure Pump for Your Needs