How to Choose the Right Hydraulic Oil Pump for Your Needs?

Choosing the right hydraulic oil pump can be challenging. The market offers various types, each with different specifications. Understanding these options is key to making an informed decision.

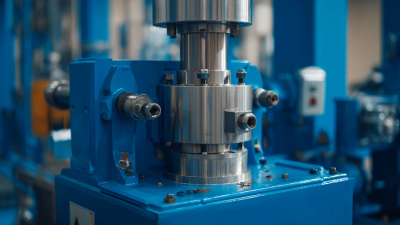

Hydraulic oil pumps are crucial in many applications. They provide power to hydraulic systems in machinery and equipment. Selecting the wrong pump can lead to inefficiencies or system failures. It is important to consider factors like flow rate, pressure, and compatibility with hydraulic fluids.

Many users overlook their specific needs. Not all pumps suit every application. Evaluating your requirements carefully can save time and money. Sometimes, the best choice might not be the most expensive one. Simple pumps can work efficiently for basic tasks. Consider all aspects to ensure optimal performance.

Understanding Hydraulic Oil Pumps: An Overview

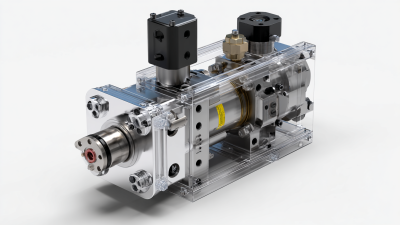

Hydraulic oil pumps are essential in various industries. They convert mechanical energy into hydraulic energy. This process powers machinery and equipment effectively. Understanding the different types of hydraulic pumps can help you make informed decisions.

There are several key components that define hydraulic pumps. They include flow rate, pressure, and efficiency. Each component affects performance and suitability for specific tasks. For instance, a high flow rate is beneficial for quick movements. However, efficiency may suffer at higher outputs. It’s crucial to consider these trade-offs.

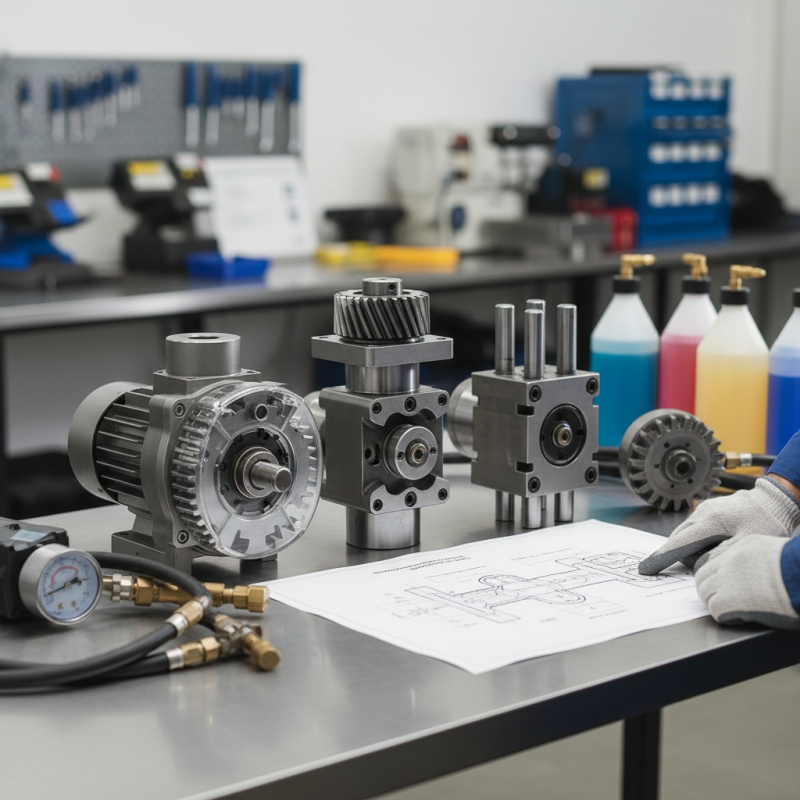

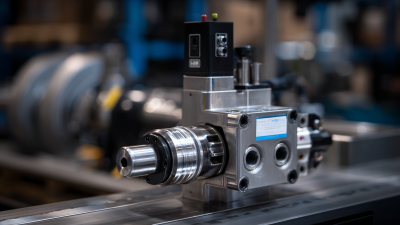

When selecting a hydraulic oil pump, it’s important to reflect on your specific needs. Consider the application and environment. An industrial setting may require more robust pumps. Conversely, lighter tasks might benefit from smaller, more compact options. Understanding your requirements can prevent costly mistakes later on.

Hydraulic Oil Pump Performance Overview

This bar chart illustrates the efficiency of different types of hydraulic oil pumps. Gear pumps offer a competitive efficiency of 85%, while piston pumps lead the category with 95%. Vane pumps and diaphragm pumps demonstrate lower efficiency rates of 75% and 65%, respectively. Understanding these performance metrics is crucial when selecting the right hydraulic oil pump for your specific needs.

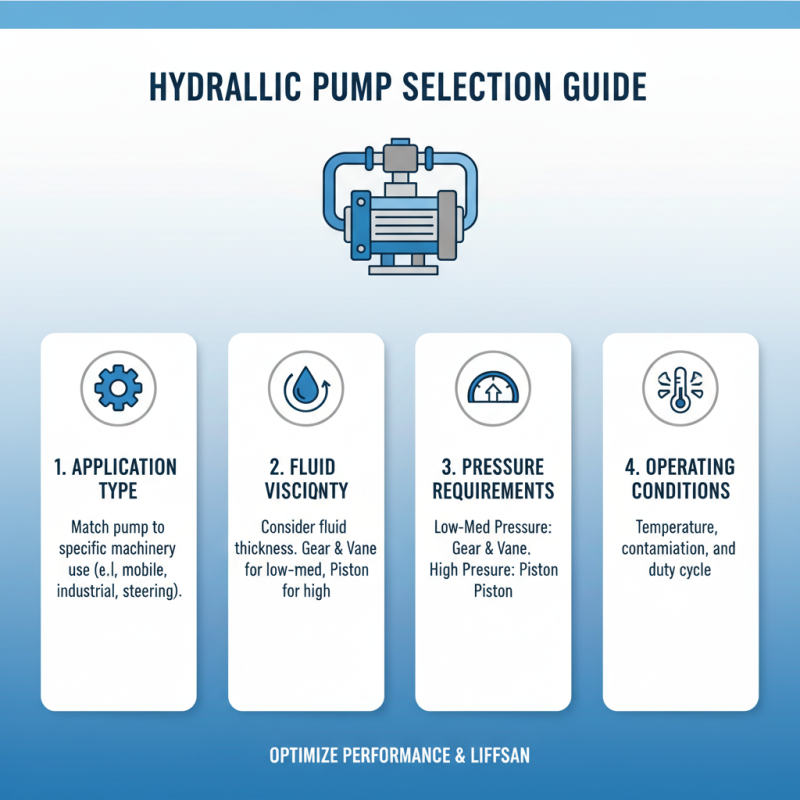

Key Factors to Consider When Choosing a Hydraulic Oil Pump

Choosing the right hydraulic oil pump involves several key factors. Understanding your specific application is crucial. Consider the type of fluids you will use. Different pumps handle different viscosities. Some designs may struggle with high-viscosity fluids. Think about the pressure requirements as well. If you need high pressure, select a pump designed for that.

Next, assess the flow rate needed for your operations. Pumps have various capacities, affecting how efficiently they perform. Too low a flow rate can slow down production. However, a pump that is too powerful wastes energy. It's essential to strike a balance.

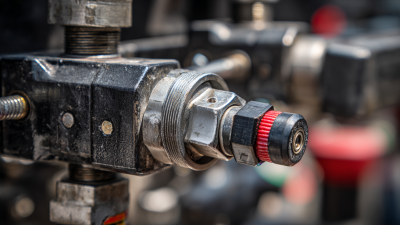

Don't overlook the installation and maintenance aspects. Some pumps are easier to install. Others require special tools. Regular maintenance is vital, too. A pump neglected may lead to costly breakdowns. Always reflect on the long-term implications of your choice. Factors like durability and wear will impact your overall experience.

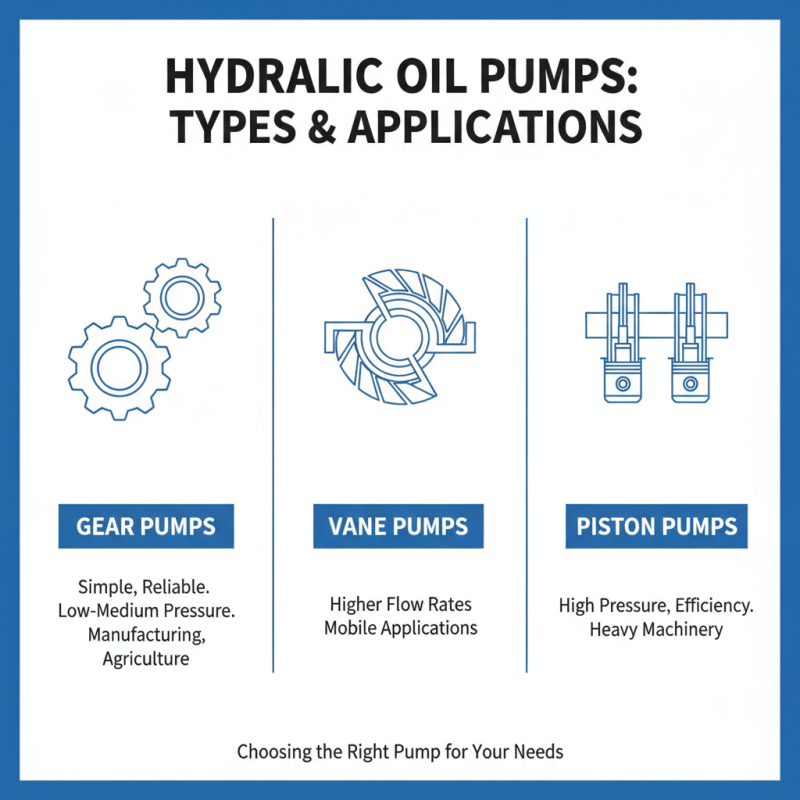

Types of Hydraulic Oil Pumps and Their Applications

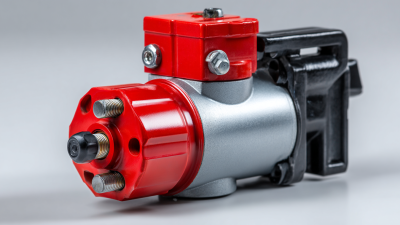

When selecting a hydraulic oil pump, understanding the types is crucial. There are gear pumps, vane pumps, and piston pumps. Each has unique features and applications. Gear pumps are simple and reliable for low to medium pressure tasks. They are common in manufacturing and agriculture. Vane pumps can handle higher flow rates and are suitable for mobile applications. Piston pumps provide high pressure and efficiency, making them ideal for heavy machinery.

Tips: Consider your specific needs. Assess the pressure and flow requirements of your system. Think about the environment where the pump will operate.

Additionally, durability matters. Look for pumps that can withstand harsh conditions. A poorly chosen pump can lead to system failures. It's easy to overlook the required maintenance. Regular checks can prolong pump life. Choose wisely to avoid costly mistakes.

Lastly, remember that installation matters. An ill-fitted pump can affect performance significantly. Review installation guidelines. Some pumps require professional setup. Take time to research the pump's compatibility with your system. This step ensures smooth operation.

Selecting the Appropriate Specifications for Your Needs

When selecting a hydraulic oil pump, understanding specifications is crucial. Output pressure, flow rate, and energy efficiency are key factors. A report from the Hydraulic Institute states that around 60% of pump failures are due to improper specification. This highlights the importance of matching pump capabilities to your specific needs.

Consider the environment where the pump will operate. For example, a cold climate might require oil that maintains viscosity at low temperatures. According to industry data, pumps operating in extreme conditions can lose up to 30% efficiency. That’s significant. Ensure the chosen pump is robust enough to handle such challenges.

Pay attention to the material of the pump components. Corrosive substances in the hydraulic fluid can lead to early wear. A study indicated that nearly 25% of mechanical failures stem from material fatigue. This points to the need for careful material selection.

Choosing the right specifications demands thorough research and consideration. It's often easy to overlook details, which could lead to costly mistakes. Each application has unique parameters, and overlooking them is a step in the wrong direction.

Maintenance Tips for Ensuring Optimal Pump Performance

Maintaining a hydraulic oil pump is crucial for optimal performance. Regular checks can prevent costly failures. Monitor oil levels frequently. Low oil can lead to overheating. This simple task keeps the pump running smoothly.

Keep an eye on the oil quality. Old or contaminated oil can damage pump components. Consider changing the oil regularly. Use a filter to catch debris. Ignoring this can result in poor efficiency.

Listen for unusual noises while the pump operates. Strange sounds may indicate wear or damage. Addressing these early can save trouble later. Pay attention to leaks as well. A small leak can escalate into a bigger issue. Staying vigilant ensures your hydraulic pump remains efficient and reliable.

How to Choose the Right Hydraulic Oil Pump for Your Needs? - Maintenance Tips for Ensuring Optimal Pump Performance

| Pump Type | Application | Flow Rate (L/min) | Pressure (bar) | Viscosity Range (cSt) | Maintenance Frequency |

|---|---|---|---|---|---|

| Gear Pump | General Industrial | 10 - 150 | 10 - 200 | 5 - 68 | Monthly |

| Piston Pump | Mobile Equipment | 5 - 120 | 20 - 300 | 10 - 200 | Bi-Weekly |

| Vane Pump | Automotive | 8 - 100 | 5 - 150 | 8 - 100 | Quarterly |

| Diaphragm Pump | Pharmaceutical | 2 - 50 | 2 - 70 | 1 - 15 | Monthly |

Related Posts

-

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

7 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025