How to Choose the Right Oil Well Pump for Your Needs?

When selecting the right oil well pump, understanding your specific needs is crucial. According to John Smith, a leading expert in the oil extraction industry, "The right pump can make or break your operation." Choosing an oil well pump involves multiple factors, including the depth of the well, production requirements, and the type of fluid being extracted. These decisions can be overwhelming.

Many operators overlook key details. For instance, the viscosity of the fluid impacts pump selection significantly. Failing to consider this can lead to inefficient operations. Additionally, the pump's material must withstand the corrosive nature of certain oils. Each choice can affect your overall productivity.

Understanding your application is vital. The wrong oil well pump can lead to downtime and increased costs. Therefore, careful assessment and expert advice are essential. Consider consulting professionals in the field. Their insights can help clarify complex choices.

Understanding Different Types of Oil Well Pumps: A Comprehensive Overview

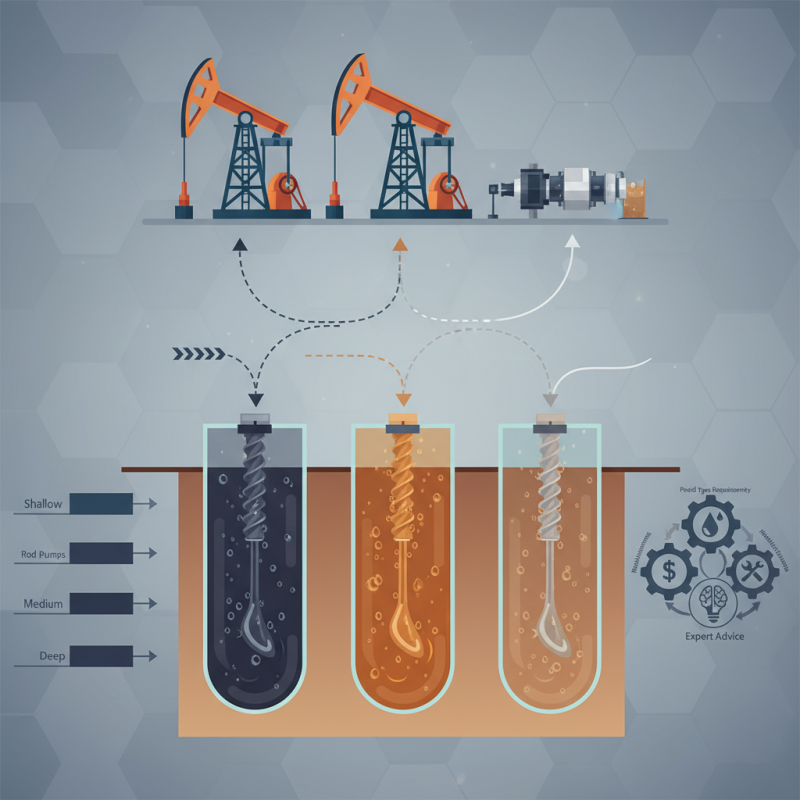

Choosing the right oil well pump can be challenging. Different types serve various functions. Understanding the specifics of each type is essential for optimal performance.

Submersible pumps operate underwater. They are efficient and often quieter. These pumps can handle high pressure but may require more maintenance. Surface pumps are another option. They stay above the well and can be less complex. However, they might not be suitable for deeper wells.

Tip: Always assess the depth of your well. This will determine what type of pump is appropriate. Also, consider the oil viscosity. Thicker oil may need a more robust pump.

Centrifugal pumps work well for lower viscosity oils. Their design helps maintain flow rates. However, they may not perform best at high pressures. Gear pumps, on the other hand, excel in transferring thicker fluids. But they could be more expensive to operate.

Tip: Analyze your budget and long-term costs. Sometimes, investing in a better-performing pump can save money over time. Don't underestimate the importance of maintenance. Regular checks can prevent costly failures.

Understanding Different Types of Oil Well Pumps

This chart provides a comparison of various types of oil well pumps based on their efficiency ratings and common usage applications.

Key Factors to Consider When Selecting an Oil Well Pump for Your Operation

When selecting the right oil well pump, various factors must be considered. The depth of the well is essential. Deep wells require pumps capable of delivering high pressure. For shallow wells, lower pressure pumps suffice. According to industry reports, nearly 30% of pump failures stem from incorrect pressure selection. It’s crucial to match pump capacity with actual well conditions.

Another key factor is the fluid characteristics. Oil density and viscosity vary. These characteristics affect pump performance. Selecting a pump unsuitable for the type of oil can lead to efficiency loss and increased downtime. Research indicates that pumps optimized for specific fluid types can improve operational efficiency by up to 20%.

Tips: Always assess the total dynamic head (TDH) requirements. This helps determine the right pump size. Regular maintenance checks can prevent unforeseen issues. Consider the materials used in the pump’s construction; they should suit the fluid’s corrosiveness. Keep in mind that selecting the wrong pump can lead to inefficiencies, resulting in higher operational costs over time.

How to Choose the Right Oil Well Pump for Your Needs?

| Criteria | Considerations | Typical Specifications |

|---|---|---|

| Well Depth | Choose a pump that can handle the depth of your oil well. | 500 - 3000 feet |

| Flow Rate | Determine the required gallons per minute (GPM) for efficiency. | 100 - 2000 GPM |

| Fluid Type | Consider viscosity and corrosiveness of the oil. | Crude oil, heavy oil, etc. |

| Pump Type | Select from submersible, mechanical, or centrifugal pumps. | Submersible, Beam Pump, etc. |

| Energy Source | Identify whether electric, gas, or solar power is preferable. | Electric, Diesel |

| Budget | Evaluate the total cost including installation and maintenance. | $5,000 - $50,000+ |

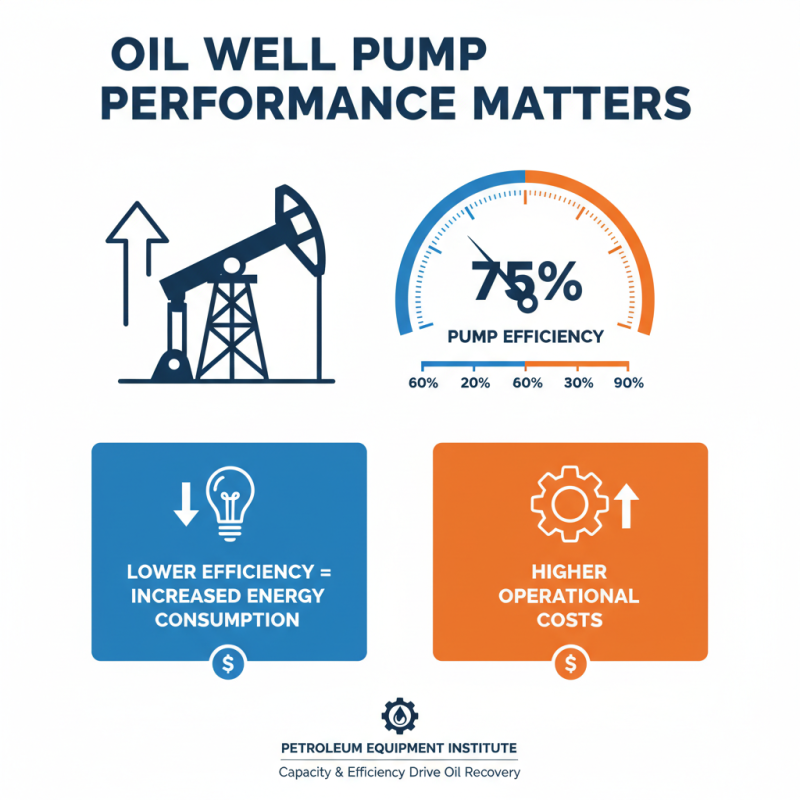

Performance Metrics: Evaluating Pump Capacity and Efficiency for Oil Recovery

When selecting an oil well pump, evaluating performance metrics is crucial. Pump capacity plays a significant role in oil recovery. According to the Petroleum Equipment Institute, a pump's efficiency can vary widely, often between 60% and 90%. A pump operating at lower efficiency can lead to increased energy consumption and higher operational costs.

Consider the specific requirements of your project. Different formations and depths require pumps with varying capacities. For instance, a deeper well may need a more robust pump with higher pressure capabilities. However, overestimating capacity can lead to unnecessary expenses. Always assess the geological conditions before making a choice. Research shows that improper pump selection can result in up to 30% reduction in output.

Efficiency also means maintaining and testing equipment regularly. Neglecting maintenance can cause performance degradation. A 2021 study revealed that 20% of pumps fail to meet their rated efficiencies due to wear and tear. This emphasizes the need for regular inspections and adjustments to enhance performance. Finding the right balance in capacity and efficiency is a complex task, but critical for optimal oil recovery.

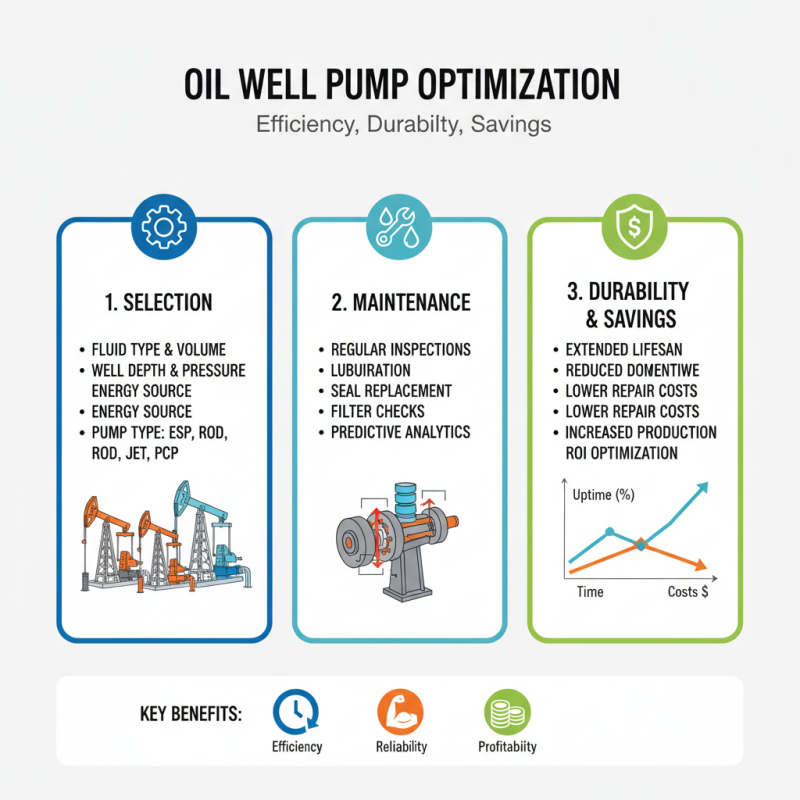

Maintenance and Durability: Ensuring Longevity of Your Oil Well Pump Choice

Selecting the right oil well pump is crucial for operational efficiency. However, maintenance and durability often determine long-term success. A well-maintained pump can significantly reduce downtime and repair costs.

According to the American Petroleum Institute, regular inspection can improve pump life by up to 30%. Key components, like seals and bearings, require frequent checks. A simple lubricant might prevent costly failures. Ignoring minor issues can lead to major breakdowns, escalating expenses over time.

Durability is not just about the materials used. Environmental factors affect longevity. For instance, extreme temperatures and corrosive elements can weaken pumps. Research shows that pumps designed with specific conditions in mind last longer. Choosing durable materials pays off, but installation quality also matters. A poorly installed pump will often underperform, regardless of its make. Therefore, adhering to best practices during installation and maintenance is essential for a pump’s lifespan.

Cost Analysis: Balancing Initial Investment and Long-Term Operation Costs

Choosing the right oil well pump often comes down to a cost analysis. The initial investment is just one piece. Long-term operation costs can significantly affect overall profitability.

According to industry reports, the initial cost of a pump can range from $15,000 to $100,000, depending on capacity and design. However, maintenance expenses can be another $5,000 annually. Poorly chosen pumps can lead to escalated costs. It's essential to evaluate performance against planned operational workflows.

Energy consumption impacts long-term expenses significantly. Some pumps can be efficient, consuming less power. Others might lead to higher energy bills over the years. Data shows that companies can save up to 20% in energy costs by selecting the right technology. These savings are crucial in tight market conditions. Inadequate research may result in higher lifetime costs, causing regret later. Making the right choice now can lead to better financial health down the road.

Related Posts

-

The Future of Oil Well Pumps Innovations and Trends Transforming the Oil Industry

-

Why Industrial Pumps Are Essential for Efficient Process Engineering in Manufacturing Industries

-

Understanding the Mechanism of Sucker Rod Pumps in Oil Extraction

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

How to Select the Right Water Well Pressure Pump for Optimal Performance and Efficiency

-

2026 How to Choose the Right Surface Jet Pump for Your Needs?