How to Choose the Right Ultra Jet Pump for Your Needs?

Choosing the right ultra jet pump is crucial for efficiency and performance. The global pump market, valued at approximately $60 billion in 2022, is projected to grow significantly. With various options available, selecting the ideal ultra jet pump can be overwhelming.

Market reports indicate that improper selection can lead to inefficiencies. Estimated costs due to wrong pump choices can exceed $1 million per year for larger operations. Understanding flow rates, pressure requirements, and application needs is essential. Each component of an ultra jet pump plays a role in its overall effectiveness.

Many users overlook their specific requirements. They often ignore crucial details such as material compatibility and maintenance needs. These oversights can lead to performance issues. Proper research helps ensure that the ultra jet pump meets both current and future demands. Selecting wisely can significantly improve productivity and save costs.

Understanding Ultra Jet Pumps: Definition, Uses, and Mechanics

Ultra jet pumps are essential tools for many applications. They efficiently move liquids from one place to another. These pumps use a jetting mechanism to create a vacuum, drawing liquid in. Understanding their operation is key to selecting the right model for your needs.

There are various uses for ultra jet pumps. They serve in agriculture, construction, and even recreational settings. The design usually includes a nozzle and a venturi chamber, which work together to increase flow rate. Choosing the wrong size or type might disrupt your project. Sometimes it's easy to overlook specifications.

Mechanical understanding is essential. The pump's efficiency relies on pressure and flow dynamics. Consider factors such as power source and liquid type. It’s a common mistake to assume one size fits all. Be mindful of installation requirements as well. Each detail can significantly impact performance, making adjustments crucial.

How to Choose the Right Ultra Jet Pump for Your Needs?

| Model | Flow Rate (GPM) | Max Pressure (PSI) | Power Rating (HP) | Applications |

|---|---|---|---|---|

| Model A | 25 | 60 | 1.5 | Irrigation, Water Supply |

| Model B | 30 | 75 | 2.0 | Pond & Fountain, Agriculture |

| Model C | 20 | 50 | 1.0 | Home Use, Light Duty |

| Model D | 35 | 85 | 3.0 | Industrial Use, Heavy Duty |

| Model E | 28 | 70 | 2.5 | Cooling Systems, HVAC |

Key Factors to Consider When Choosing an Ultra Jet Pump

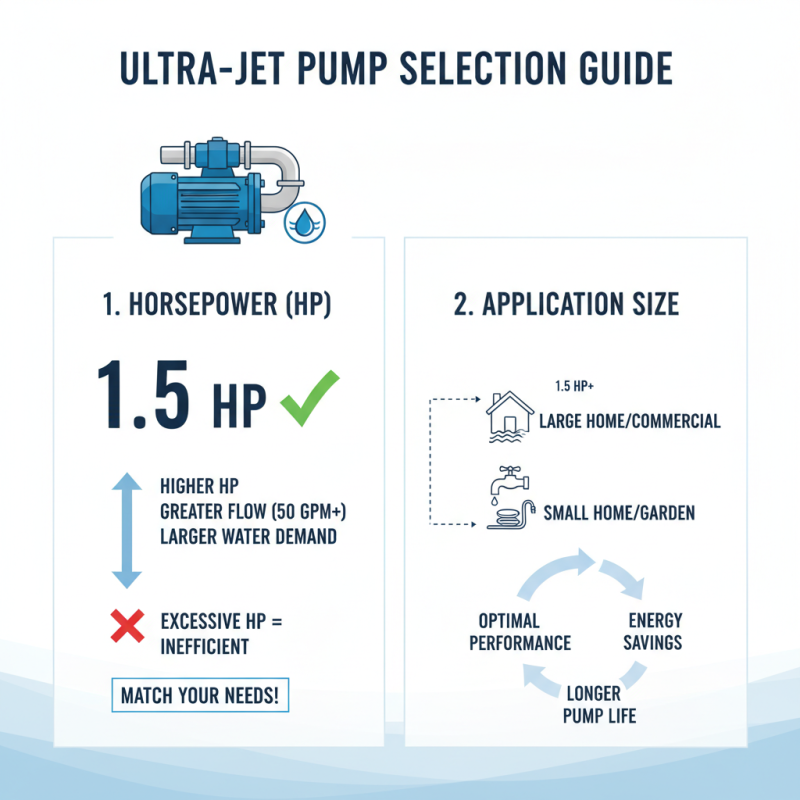

When choosing an ultra jet pump, several key factors come into play. First, consider the pump's horsepower. Pumps with higher horsepower have greater flow rates and can handle larger water demands. For instance, reports indicate that pumps with 1.5 HP can yield up to 50 gallons per minute, making them suitable for larger applications. However, excessive horsepower can lead to inefficiencies. It's crucial to match the horsepower to your specific needs to avoid wasting energy.

Next, examine the materials used in the pump's construction. Common materials include stainless steel and thermoplastic. Stainless steel offers durability and resistance to corrosion, which is vital for long-term performance. However, it may be heavier and more costly. Thermoplastic, on the other hand, is lightweight and less expensive but might not withstand harsher conditions. This trade-off is worth reflecting on when you consider your environment and usage.

Lastly, the pump's application type is important. Some pumps are designed for clean water only, while others can handle solids or contaminants. For instance, submersible pumps designed for sewage can typically manage up to 2-inch solids. Knowing your application's specific requirements ensures you choose the right model. Balancing these factors can be challenging, but it is essential for effective pump selection.

Evaluating Pump Performance: Flow Rate and Head Challenges

When choosing an ultra jet pump, consider the flow rate and head challenges carefully. The flow rate indicates how much water the pump can move within a certain time. For instance, a pump with a high flow rate is essential for large irrigation systems or residential applications. However, not all applications need high flow. Sometimes, a lower flow with improved overall efficiency is better.

Head is equally important. It measures the height water can reach. If you need to pump water uphill or over long distances, consider the total dynamic head. This measurement is crucial for ensuring the pump can meet your demands. If the head is too low, the system won't be effective. You may find that pumps with high flow rates struggle with head, leading to poor performance.

Evaluate these factors against your needs. A mismatch can lead to wasted energy and increased costs. Too high a flow can cause water to move too quickly, creating pressure issues. Too low a head might result in inadequate delivery. Reflections on system requirements often reveal gaps in understanding. Don’t rush the selection process; it can lead to regrets later.

Evaluating Ultra Jet Pump Performance

This chart compares the flow rate and head capabilities of three different ultra jet pumps, providing a visual representation to help identify the best option for specific needs based on performance metrics.

Material and Size Specifications: Matching Pumps to Applications

Choosing the right ultra jet pump starts with understanding material and size specifications. Different applications require specific materials. For example, stainless steel is often favored in corrosive environments. According to industry reports, about 70% of pumps for agricultural uses are made from durable plastic. This choice can reduce costs significantly.

Size matters too. A pump that is too small may falter under high demand. A precise match can enhance efficiency. Studies suggest that inappropriate sizing can lead to a 15% drop in performance. Each application has unique flow and pressure requirements.

Remember, not all pump installations are perfect. Sometimes, users overlook vapor lock issues. Misaligned pipes can cause inefficiencies. It’s essential to assess operational conditions regularly. A well-suited pump performs better, but only if the surrounding systems are equally effective. Keep these factors in mind for optimal results.

Cost Analysis: Balancing Budget with Performance Requirements

When selecting an ultra jet pump, cost is a primary concern. You must balance your budget with the performance you require. A higher initial investment often leads to better efficiency and durability. However, it is crucial to assess whether you can justify the extra cost based on your specific needs.

Look closely at the features that matter most to you. Do you need high flow rates, or is energy efficiency your top priority? Sometimes, mid-range pumps offer satisfactory performance without breaking the bank. Yet, consider hidden costs like maintenance and energy consumption. These ongoing expenses can quickly add up over time.

Choosing the right pump requires careful thought. It’s essential to evaluate both short-term and long-term impacts. You may be tempted by low-priced options that promise excellent results. However, think about how they may perform over the years. An inexpensive initial option may lead to inadequate performance, requiring replacements sooner than expected. Balancing budget and performance is not easy, but it’s vital for a wise investment.

Related Posts

-

Exploring Market Trends: Ultra Jet Pumps at the 138th Canton Fair 2025 in China

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

2026 How to Choose the Right Surface Jet Pump for Your Needs?

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

How to Select the Right Water Well Pressure Pump for Optimal Performance and Efficiency