Effective Solutions for Pumping Water with Solution Pump Tips You Need to Know

In the realm of fluid management, effective water pumping is essential for various applications, ranging from agricultural irrigation to industrial processes. One of the most reliable methods for achieving this is through the use of a solution pump. These specialized pumps are designed to handle different types of fluids, ensuring efficiency and durability in demanding environments. Understanding the intricacies of solution pumps not only enhances their operational capabilities but also extends their lifespan, ultimately leading to significant cost savings.

In this guide, we will explore effective solutions for pumping water, focusing on the critical tips you need to know about solution pumps. Whether you're a seasoned professional or a novice, familiarizing yourself with these key insights will empower you to optimize your pumping systems. From choosing the right pump to maintenance practices, we aim to provide a comprehensive overview that will facilitate your success in fluid management. Join us as we dive into the essential aspects of solution pumps and uncover strategies that can transform your water pumping processes.

Overview of Water Pumping Systems and Their Applications

Water pumping systems are essential for various applications across multiple industries, from agriculture to construction. According to a report by the International Water Association, approximately 70% of water extracted globally is used for agricultural purposes. Efficient water pumping is crucial to optimizing irrigation systems, ensuring crops receive adequate moisture while conserving water resources. The selection of appropriate pumping technology, such as centrifugal or positive displacement pumps, can significantly influence water delivery efficiency, directly impacting productivity.

In urban settings, water pumping systems serve vital roles in municipal water supply and wastewater management. The American Society of Civil Engineers (ASCE) highlights that aging infrastructure in several cities leads to increased energy consumption in water distribution, emphasizing the need for modern solutions. Innovations such as programmable pump controllers and energy-efficient designs can reduce operational costs by up to 30%, aligning with sustainability goals while maintaining service reliability. Properly designed pumping systems not only meet immediate water demands but also contribute to long-term resource management.

Water Pumping Systems Efficiency by Type

Key Types of Pumps for Efficient Water Transfer

When it comes to efficient water transfer, selecting the right type of pump is crucial. The most commonly used pumps include centrifugal pumps, submersible pumps, and diaphragm pumps. According to industry reports, centrifugal pumps account for nearly 80% of all pumps in use today, primarily due to their efficiency in moving large volumes of water quickly. They operate by converting rotational energy into hydrodynamic energy, making them ideal for applications in agriculture, water treatment, and industrial processes.

Submersible pumps, on the other hand, are designed to operate while submerged in water. These pumps are particularly effective for draining basements or emptying flooded areas, with the ability to handle solids up to a certain diameter, depending on the model. Diaphragm pumps are another key player, particularly where precise flow control is necessary. They use a flexible diaphragm to create pressure changes, allowing for the transfer of viscous liquids and slurries without the need for additional components.

Tips for selecting the right pump: include assessing the specific requirements of your application, including flow rate and total dynamic head. It’s also crucial to consider the pump material; for instance, stainless steel may be preferable for corrosive environments. Regular maintenance is essential to extend the lifespan of your pump and ensure optimal performance. Monitoring signs of wear and tear can prevent costly replacements down the line, ensuring efficiency is maintained throughout its service life.

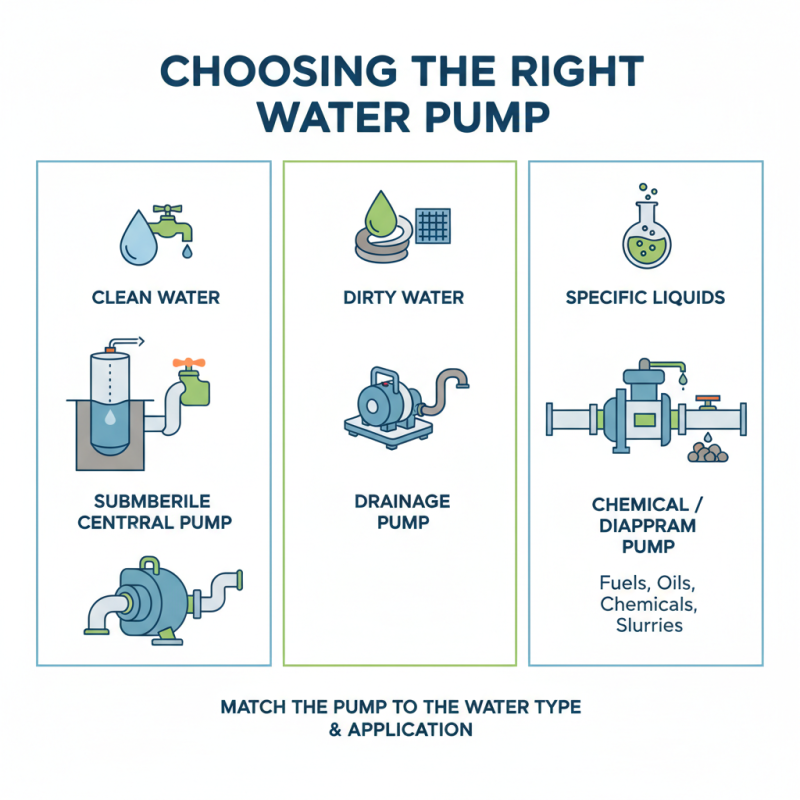

Essential Tips for Choosing the Right Pump for Your Needs

Choosing the right pump for your water needs can be a daunting task, but understanding some essential tips can simplify the process. First, it’s crucial to determine the type of water you need to pump—whether it’s clean water, dirty water, or specific liquids. This will guide you in selecting a pump designed for that purpose. For clean water, submersible pumps or centrifugal pumps work well, while dirty water may require drainage or sewage pumps. Knowing your specific application helps in narrowing down your options effectively.

Next, consider the flow rate and head height requirements. The flow rate indicates how much water the pump can move per minute, while the head height defines the vertical distance the pump can lift water. It's important to match these specifications with your project needs; otherwise, you may end up with a pump that underperforms or is overbuilt for the job. Additionally, evaluating the pump’s power source—electric, gas, or solar—can impact usability and efficiency based on your location and available energy sources. By clearly identifying your requirements and understanding these critical factors, you will be well on your way to making an informed decision.

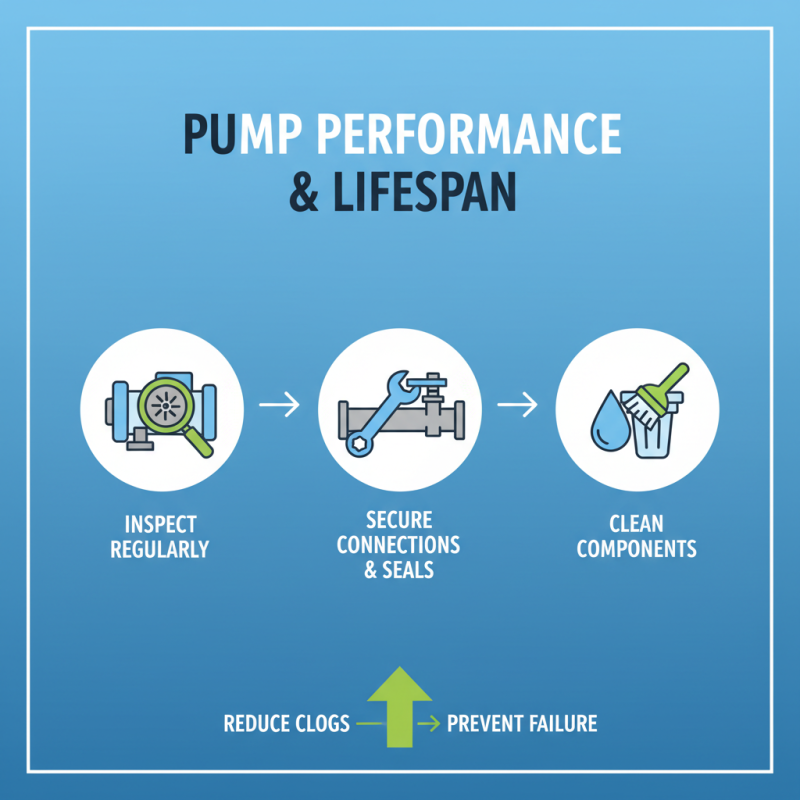

Maintenance Practices to Enhance Pump Performance and Longevity

Proper maintenance practices are essential for enhancing pump performance and extending its lifespan. Regular inspection of the pump system is crucial. Operators should routinely check for leaks, unusual noises, or vibrations, which may indicate underlying issues. Ensuring that all connections and seals are tight can prevent leaks and maintain efficiency. Additionally, cleaning the pump and its components, such as filters and strainers, helps reduce the risk of clogs that could impede water flow and lead to pump failure.

Lubrication is another vital aspect of pump maintenance. Ensuring that bearings and other moving parts are properly lubricated helps minimize wear and tear, resulting in smoother operation. It’s important to follow the manufacturer’s guidelines regarding lubricants and intervals for application. Furthermore, monitoring the pump’s operating conditions, such as temperature and pressure, can provide valuable insights into its health and alert operators to any potential issues before they escalate. By implementing these maintenance practices, pump operators can significantly enhance the efficiency and longevity of their water pumping systems.

Common Challenges in Water Pumping and How to Overcome Them

Pumping water effectively can often present various challenges that need to be addressed for optimal performance. One of the most common issues is airlock, which occurs when air gets trapped in the pump or the line, preventing water from flowing. To overcome this, it's important to ensure the system is properly primed and to install air release valves. Regular maintenance and checks can also help identify air pockets that may need to be bled out to ensure consistent operation.

Another significant challenge is the variation in water quality, which can lead to clogging and decreased efficiency. Sediment and debris in the water can cause pumps to wear out prematurely or fail altogether. To tackle this problem, consider implementing filtration systems to remove larger particles before water reaches the pump. Additionally, routine inspections can catch buildup early, allowing for timely cleaning or replacement of components. Using pumps designed to handle specific water conditions can also enhance longevity and reliability.

Related Posts

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump

-

Mastering Sucker Rod Pump Efficiency through Advanced Techniques and Industry Insights

-

What is a Flo Jet Pump and How It Enhances Efficiency in Water Circulation Systems

-

The Ultimate Guide to Choosing the Best Water Well Jet Pump

-

How to Choose the Right Water Well Pump for Your Home Needs

-

Ultimate Guide to Fracking Pump Maintenance Checklist for Optimal Performance