How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

Maintaining your hydraulic gas pump is essential for ensuring its optimal performance and longevity. A well-maintained hydraulic gas pump not only enhances productivity but also minimizes the risk of costly repairs and downtime. In this guide, we will explore effective maintenance practices that can be easily integrated into your regular routine. From routine inspections to proper lubrication techniques, we’ll cover all the key aspects that contribute to the efficient operation of your hydraulic gas pump. Understanding the importance of these maintenance tasks will help you identify potential issues early on, ensuring that your equipment runs smoothly and reliably over time. Whether you are a seasoned technician or a novice user, mastering these maintenance tips will empower you to take control of the performance of your hydraulic gas pump, ultimately leading to greater efficiency and savings.

Importance of Regular Maintenance for Hydraulic Gas Pumps

Regular maintenance of hydraulic gas pumps is crucial for ensuring optimal performance and longevity. According to the Hydraulic Institute, neglecting routine checks can lead to a decrease in efficiency by as much as 25%. Given that hydraulic systems often operate under high pressure and demanding conditions, a minor oversight can result in significant operational issues, increased downtime, and costly repairs. Investing in maintenance not only extends the lifespan of these pumps but also enhances their reliability, making it a vital aspect of any operational strategy.

Furthermore, a study from the American Society of Mechanical Engineers emphasizes that regular maintenance can lower the risk of pump failures by 40%. Key practices such as monitoring fluid levels, checking for leaks, and inspecting seals and hoses can help prevent unplanned stoppages. In addition, it’s essential to adhere to manufacturers' recommendations on service intervals and to utilize high-quality replacement parts to maintain efficiency. In an industry where performance directly impacts productivity and profitability, prioritizing the maintenance of hydraulic gas pumps is not just prudent — it’s essential for sustained operational success.

Key Components to Inspect for Optimal Performance

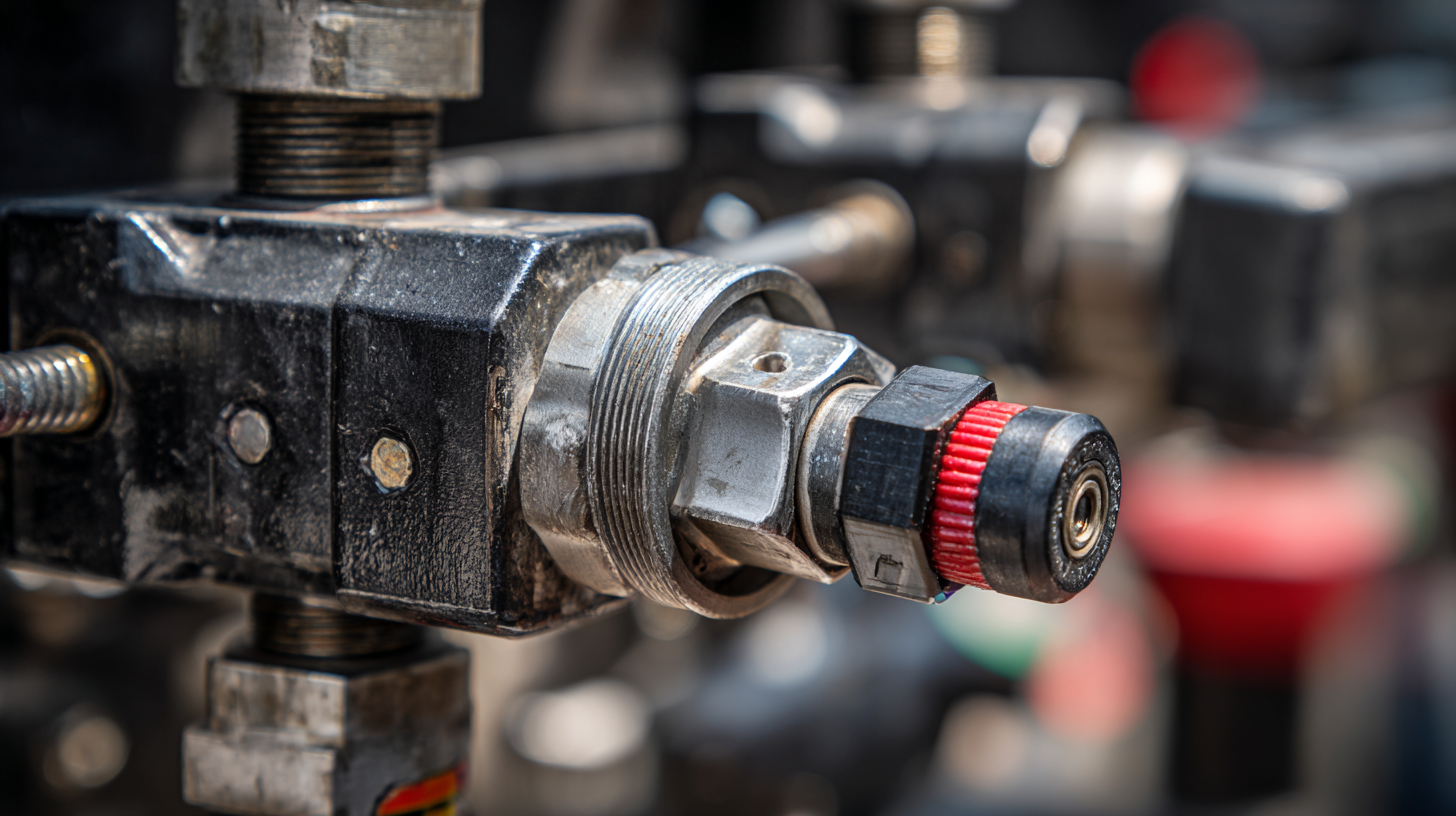

When it comes to maintaining your hydraulic gas pump for optimal performance, focusing on key components is crucial. Regular inspections can prevent significant issues and enhance the efficiency of the system. Begin with the oil reservoir, ensuring that the hydraulic fluid is at the right level and free from contaminants. Dirty or low fluid can lead to pump wear and reduced performance, so changing the oil according to the manufacturer’s recommendations is vital.

Next, pay attention to the seals and gaskets. These components are essential for preventing leaks and maintaining pressure within the system. Inspect them for signs of wear or damage, and replace any that are not performing adequately. Additionally, the pump's filters should be checked regularly; clogged filters can hinder flow and risk putting additional strain on the pump. By focusing on these critical elements—oil reservoir, seals, and filters—you can significantly extend the lifespan of your hydraulic gas pump and ensure it operates at peak efficiency.

Step-by-Step Maintenance Procedures for Hydraulic Gas Pumps

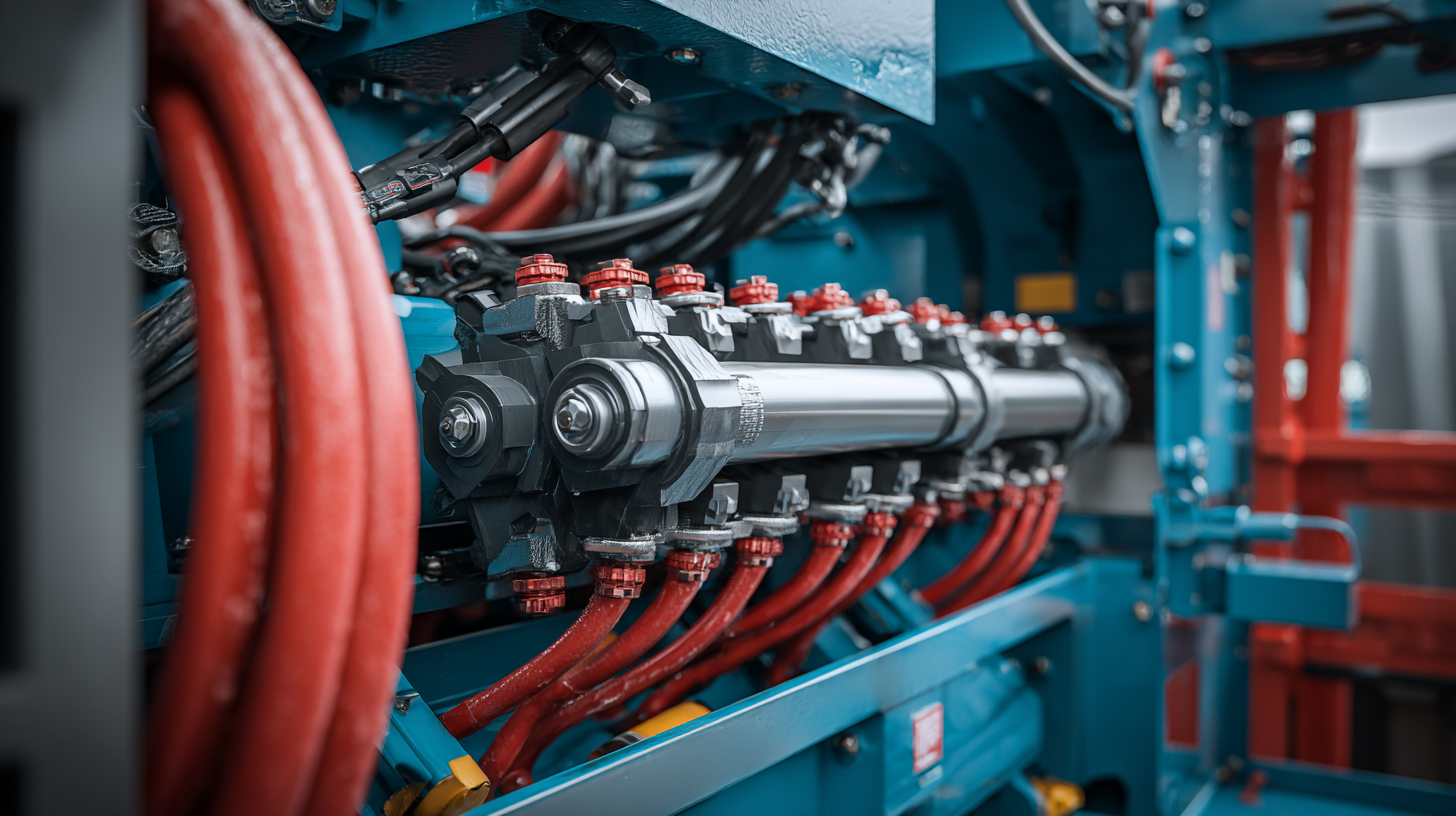

When it comes to maintaining hydraulic gas pumps for optimal performance, implementing a systematic approach is crucial. First and foremost, regular inspections should be carried out to identify any potential issues before they evolve into significant problems. A study focusing on preventive maintenance across various fleets indicates that businesses can improve fuel efficiency by as much as 8% with consistent upkeep. This underscores the importance of regularly checking fluid levels, monitoring for leaks, and ensuring that all components are in good condition.

Additionally, operators should follow a step-by-step maintenance procedure that includes cleaning filters and screens, checking pressure settings, and assessing wear on critical components. Proper installation of the pump is similarly vital; for instance, draining the oil from the hydraulic system before installation can help prevent contamination. Neglecting these steps not only hampers the pump's efficiency but can also lead to costly downtime. Following these maintenance protocols ensures your hydraulic gas pump operates at peak performance, contributing to overall system reliability and efficiency.

Hydraulic Gas Pump Maintenance Performance

This chart displays the effect of regular maintenance on the efficiency of hydraulic gas pumps over a six-month period.

Common Issues and Troubleshooting Tips

Hydraulic gas pumps are crucial components in various industrial applications, but they can encounter issues that impede optimal performance. Common problems include leaks, reduced pressure, and abnormal noises. According to a report by the International Fluid Power Society, 60% of hydraulic system failures can be attributed to improper maintenance. Regular inspections and maintenance routines are vital in preventing these failures and ensuring long-lasting pump functionality.

One effective tip for troubleshooting is to regularly check for leaks around the pump seals and fittings. Even a small leak can lead to significant pressure loss and lower efficiency. Additionally, monitoring fluid levels and quality will help detect contaminants that might affect performance. The fluid should be replaced or filtered if it appears dirty or has an unusual odor.

Another critical aspect is to listen for any unusual sounds coming from the pump, such as grinding or whining, which could indicate internal wear or damage. Addressing these noises promptly can prevent more severe issues down the line. Routine maintenance checks, such as replacing worn components and ensuring that the pump operates within its specified pressure ranges, can further enhance reliability and performance.

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance - Common Issues and Troubleshooting Tips

| Issue | Symptoms | Possible Causes | Troubleshooting Steps | Maintenance Tips |

|---|---|---|---|---|

| Low Pressure | Inconsistent power output | Air leaks, clogged filters | Check for leaks and replace filters | Regularly inspect fittings and seal integrity |

| Overheating | Temperature warning lights | Low fluid levels, faulty thermostat | Inspect fluid levels and thermostat functionality | Change fluids according to schedule |

| Unusual Noises | Grinding or rattling sounds | Worn bearings, low oil | Inspect bearings and check oil levels | Lubricate moving parts regularly |

| Fluid Contamination | Discoloration or particles in fluid | Contaminated filters or environment | Replace fluid and clean the system | Change filters regularly and monitor environment |

Best Practices for Longevity and Efficiency in Hydraulic Gas Pumps

Maintaining hydraulic gas pumps is crucial for ensuring their longevity and efficiency. According to a report from the Hydraulic Institute, proper maintenance can enhance the lifespan of hydraulic systems by up to 30%, significantly reducing the need for costly replacements. Regular inspections and maintenance practices such as monitoring fluid levels, checking for leaks, and replacing worn-out seals are essential in preventing breakdowns and maximizing performance. Ensuring that the pump operates within its optimal pressure range helps avoid unnecessary strain on the components, leading to smoother operation and energy savings.

Another industry study highlights that most failures in hydraulic gas pumps stem from inadequate lubrication and contamination of the hydraulic fluid. Implementing a robust filtration system and adhering to routine lubricant checks can decrease these risks considerably. Furthermore, leveraging condition monitoring technologies can provide real-time insights into the pump's performance, allowing for timely interventions that keep the system running efficiently. By following these best practices, operators can achieve not only improved performance but also a substantial return on investment in their hydraulic gas pump systems.

Related Posts

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

Mastering Sucker Rod Pump Efficiency through Advanced Techniques and Industry Insights

-

5 Essential Tips to Maximize Efficiency with Ultra Jet Pumps in Your Industry

-

Ultimate Guide to Fracking Pump Maintenance Checklist for Optimal Performance

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data