What is an ESP Pump and How Does It Work?

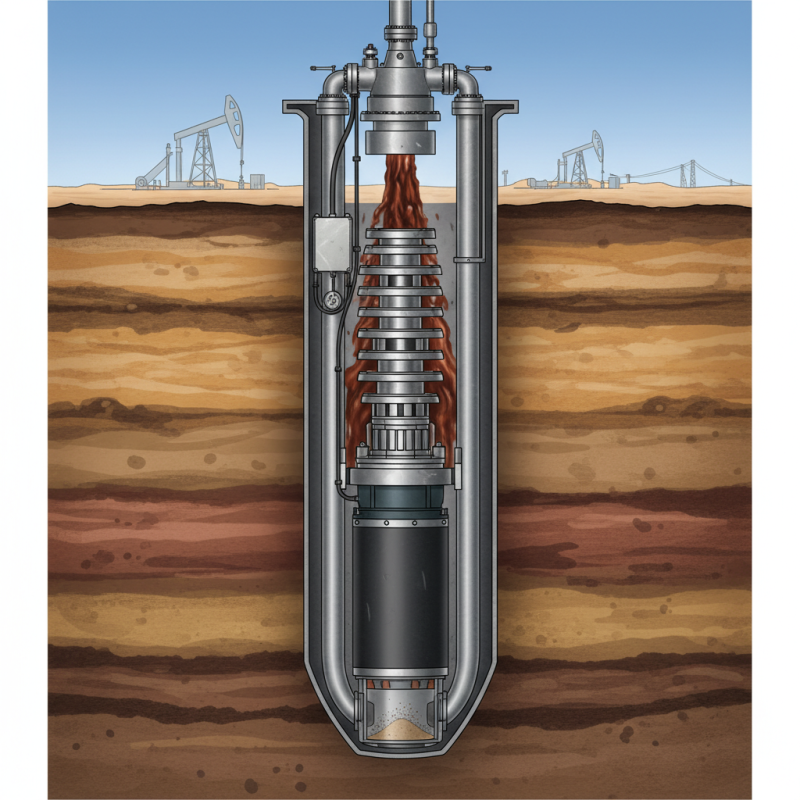

An ESP pump, or electrical submersible pump, plays a crucial role in oil production. According to Dr. Emily Carter, a leading expert in petroleum engineering, "The ESP pump is vital for efficient oil extraction." This technology operates by using a multi-stage centrifugal pump powered by a motor located at the bottom of the well. It pushes fluid from deep reservoirs to the surface.

However, despite its efficiency, challenges exist. Common issues include wear and tear from harsh environments, scaling, and maintenance costs. Many operators overlook the importance of regular monitoring. This oversight often leads to unexpected failures, disrupting production.

Understanding the mechanics of the ESP pump is essential for modern oil fields. Operators need to balance efficiency with the harsh conditions of deep wells. Only with careful planning can they maximize the benefits of this technology.

What is an ESP Pump?

An ESP pump, or Electric Submersible Pump, is a device designed to lift fluids from deep underground reservoirs. It operates by converting electrical energy into mechanical energy, allowing it to pump liquids efficiently. The pump is entirely submerged in the fluid it is moving. This unique feature allows it to manage high-pressure conditions often found in oil and gas wells.

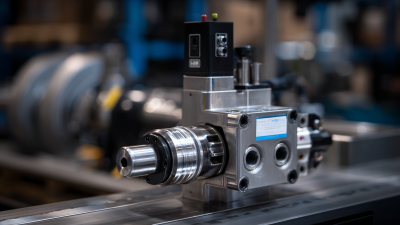

ESP pumps consist of several components, including a motor, pump stages, and a power cable. The motor drives the pump stages, which increase the pressure of the fluid. It's important to choose the right size and model according to the specific requirements of the well. Incorrect specifications can lead to pump damage or inefficiency.

Tips: Always monitor the pump's performance. Regular maintenance checks can prevent unexpected failures. Listen for abnormal sounds, as they can indicate issues. Accurate data collection is vital for successful operations. Adaptation is necessary when conditions change over time in the reservoir. Each installation is unique, and what works for one site may not be ideal for another. Adjust accordingly.

Key Components of an ESP Pump

An Electrical Submersible Pump (ESP) is a vital tool in various industries. Understanding its key components helps in grasping how it functions. The ESP mainly consists of a motor, a pump, and a cable.

The motor, usually submerged, drives the pump. It converts electrical energy into mechanical energy. An important part of the motor is the stator. It creates a magnetic field necessary for the rotor to spin. Tips: Always check the motor's insulation for wear. Poor insulation can lead to failures.

The pump is typically multistage. It boosts the fluid to the surface effectively. Each stage adds to the pressure required to lift the fluid. That means if one stage fails, performance drops. Keep an eye on performance metrics. Abrasive fluids can shorten the pump’s lifespan. Tips: Regular monitoring can catch issues early.

The cable connects the motor to the power source. It must withstand harsh conditions. Issues here can cause pump failure. Improperly insulated cables lead to downtime. Therefore, regular maintenance is crucial. Tips: Inspect cables for corrosion regularly. A small issue can lead to large problems.

How an ESP Pump Operates

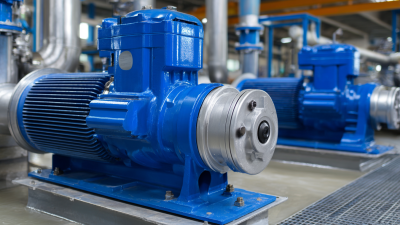

An ESP pump, or electrical submersible pump, is a crucial tool in various industries. It is widely used in oil extraction and water supply systems. Understanding how an ESP pump operates can help optimize its efficiency.

An ESP consists of multiple components. The motor, typically at the bottom, drives the pump. Above that, a series of centrifugal pumps work together to lift fluid. The entire assembly is submerged in the fluid it pumps. This is crucial for cooling the motor. When the motor spins, the impellers create pressure, pushing the fluid upwards.

However, ESP systems can encounter issues. Blockages can occur in the pump or pipes. This often leads to reduced efficiency. Regular maintenance is essential to avoid such problems. Without it, you could face significant downtime. The temperature of the fluids can also affect performance. High temperatures may damage the motor. Understanding these variables is key to success.

Applications of ESP Pumps in Industry

Electric Submersible Pumps (ESPs) are widely used in various industries for their reliability and efficiency. In oil and gas, the demand for ESPs is significant. According to a report by Global Market Insights, the ESP market is projected to reach over $6 billion by 2026. These pumps effectively transport fluids from deep wells, overcoming high pressures with ease. They are ideal for extracting crude oil and natural gas from remote locations.

In the water treatment sector, ESPs are increasingly critical. They facilitate the pumping of groundwater in areas suffering from drought. A study from Water Technology highlighted that ESP technology can reduce energy consumption by up to 30% compared to traditional methods. This advantage is crucial for sustainable water management. However, it’s important to recognize the challenges. Maintenance and operational complexities can hinder performance, leading to unexpected downtime in critical applications.

Moreover, the mining industry uses ESPs for dewatering processes. These pumps help manage water accumulation in mines, ensuring safety and efficiency. However, variations in geology can affect pump efficiency. A survey showed that some sites reported up to 15% lower performance than expected. This disparity requires ongoing assessment and adaptation to enhance operational reliability. As industries continue to innovate, ESPs will play a vital role in meeting future challenges.

Applications of ESP Pumps in Industry

Maintenance and Troubleshooting of ESP Pumps

Maintenance of ESP pumps is crucial for optimal performance. Regular monitoring ensures that the pump runs efficiently, reducing operational costs. For instance, the 2021 Pump Industry report indicated that 30% of ESP failures stem from inadequate maintenance. Daily checks on fluid levels and the condition of the power source can prevent unexpected breakdowns.

Troubleshooting common issues like overcurrent or vibration is important. When encountering these problems, check for debris or blockages in the system. A quick inspection might reveal simple fixes that save time and money. Ensure proper alignment and verify that the motor is functioning within its recommended parameters. Addressing these elements can lead to a 15% increase in reliability.

Tips: Clean the pump and surrounding area regularly. Keep spare parts on hand for swift repairs. Document all maintenance activities to track performance trends. Neglecting these practices often leads to larger issues down the line. Regular maintenance and proactive troubleshooting can enhance the life expectancy of ESP pumps significantly. Avoid complacency; a small issue today can escalate quickly tomorrow.

What is an ESP Pump and How Does It Work? - Maintenance and Troubleshooting of ESP Pumps

| Dimension | Description | Typical Values |

|---|---|---|

| Pump Type | Electrical Submersible Pump | Used in oil and water extraction |

| Operating Depth | Depth at which the pump operates | Up to 10,000 feet |

| Flow Rate | Volume of fluid the pump can move | 100-1500 m³/day |

| Efficiency | Energy efficiency of the pump | 70-90% |

| Common Issues | Typical problems faced during operation | Overheating, blockage, failure of motor |

| Maintenance Frequency | Recommended frequency of maintenance checks | Every 6-12 months |

Related Posts

-

How to Optimize Production with Artificial Lift Pumps: Enhancing Efficiency in Oil Wells

-

10 Best Sucker Rod Pumps for Efficient Oil Extraction in 2023

-

How to Optimize Oilfield Jet Pump Efficiency: Tips & Industry Insights

-

The Future of Oil Well Pumps Innovations and Trends Transforming the Oil Industry

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

2025 Top 5 Industrial Pumps: Best Picks for Efficiency and Performance