10 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

Choosing the right hydraulic oil pump is a critical decision that can significantly impact the efficiency and performance of hydraulic systems across various industries. According to a report from the International Hydraulics Industry Association, the global hydraulic pumps market is projected to reach $20 billion by 2026, with a compound annual growth rate (CAGR) of approximately 5.5%. This growth underscores the importance of selecting the appropriate hydraulic oil pump, as even minor discrepancies in pump selection can lead to increased maintenance costs and reduced operational efficiency.

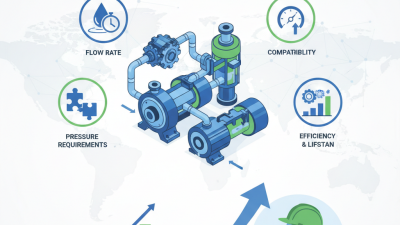

When evaluating hydraulic oil pumps, several factors need to be considered, including flow rate, pressure range, and operational compatibility with existing systems. Additionally, the selection process must be informed by specific application requirements and the working environment. As evidenced by various case studies, improper selection of hydraulic oil pumps can lead to system failures, which not only disrupt production but can also incur significant costs related to repairs and replacements. Thus, navigating the complexities of hydraulic oil pump selection is essential for maximizing system performance and longevity.

Understanding Hydraulic Oil Pump Basics and Functions

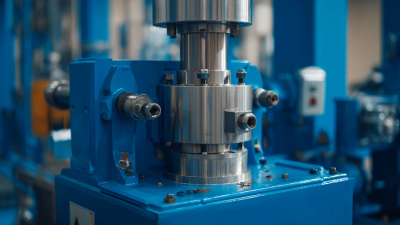

Hydraulic oil pumps play a crucial role in the efficiency and performance of hydraulic systems. At their core, these pumps convert mechanical energy into hydraulic energy, generating fluid flow that powers various equipment. Understanding their basic functions is essential when selecting the right pump for your specific needs. Hydraulic oil pumps operate by creating a vacuum that draws fluid from the reservoir and then pressurizing it to move through the system. This pressure allows for the operation of hydraulic cylinders, motors, and other components.

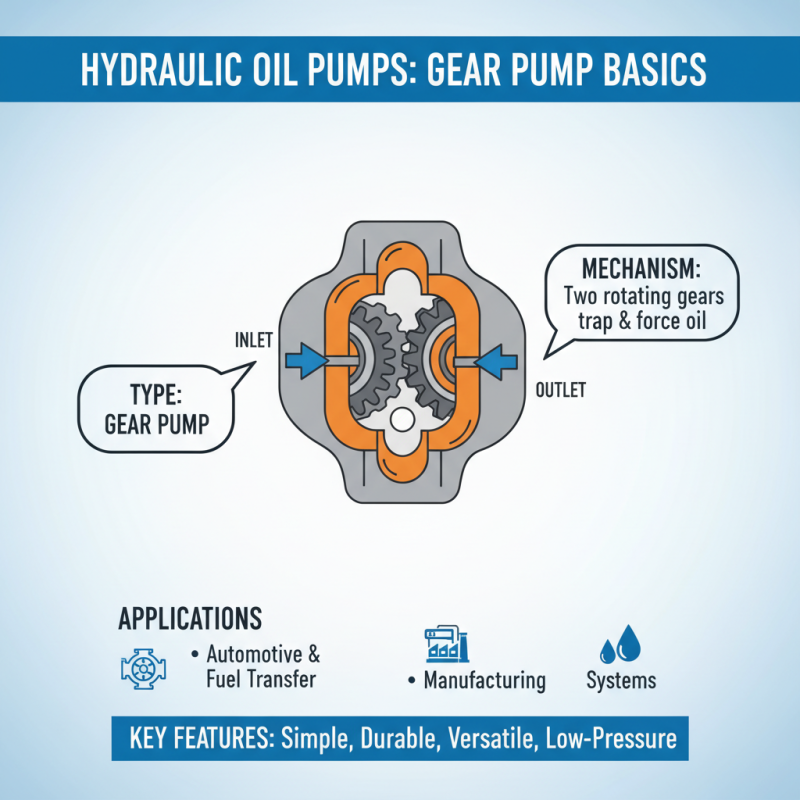

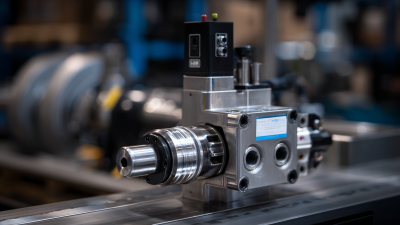

When considering a hydraulic oil pump, it’s important to identify the type of application you will be using it for. Different pumps serve different functions, such as gear pumps, vane pumps, and piston pumps, each with its own advantages and limitations. For instance, gear pumps are known for their simplicity and high reliability, making them suitable for many industrial applications, while piston pumps are ideal for high-pressure scenarios. Further, factors such as flow rate, pressure rating, and fluid compatibility must be taken into account to ensure optimal performance and longevity of the hydraulic system. Understanding these basics lays the foundation for selecting a hydraulic oil pump that meets your operational requirements efficiently.

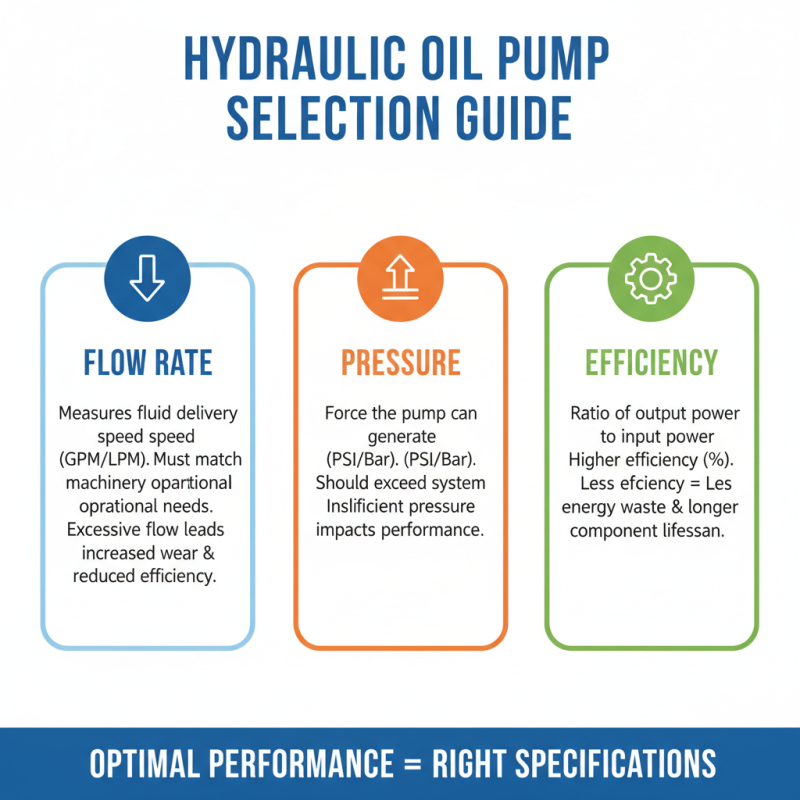

Hydraulic Oil Pump Selection Factors

This chart illustrates the typical values relevant to selecting the right hydraulic oil pump based on essential factors such as flow rate, pressure rating, viscosity, service life, and cost.

Key Factors to Consider When Selecting a Hydraulic Oil Pump

When choosing the right hydraulic oil pump for your needs, several key factors must be considered to ensure optimal performance and reliability. One of the most critical aspects is determining the pump's flow rate requirements, which is essential for matching the pump's capacity with the system demands. It's important to evaluate the specific application to calculate the required flow at the appropriate pressure, ensuring that the pump can deliver the necessary performance without overloading.

Another essential tip is to assess the compatibility of the hydraulic oil with the pump materials. Different oils have varying chemical properties, and selecting a pump that works well with your specific hydraulic fluid can significantly affect the longevity and effectiveness of your system. Additionally, consider the pump's operating environment, including temperature ranges and potential exposure to contaminants, to choose a model designed to cope with these conditions.

Moreover, be mindful of the pump’s energy efficiency and maintenance requirements. Opting for a pump that operates efficiently not only reduces energy costs but also minimizes wear and tear over time, resulting in lower maintenance needs. Regular maintenance can prevent costly downtimes and extend the life of the pump, so it's crucial to factor in how easy it is to maintain the pump as part of your selection criteria. By considering these key factors, you can ensure that you select a hydraulic oil pump that meets your operational needs and contributes to the overall efficiency of your machinery.

Evaluating Pump Specifications: Flow Rate, Pressure, and Efficiency

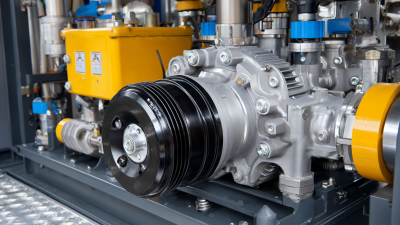

When selecting the right hydraulic oil pump, understanding the key specifications such as flow rate, pressure, and efficiency is crucial to ensuring optimal performance for your specific application. Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), determines how quickly the hydraulic fluid is delivered through the system. According to industry reports, the ideal flow rate should meet the operational requirements of your machinery while minimizing energy consumption. For example, an excessive flow rate can lead to increased wear on components and reduced system efficiency, potentially shortening the lifespan of critical equipment.

Pressure ratings, typically expressed in pounds per square inch (PSI) or bar, are equally significant when choosing a hydraulic oil pump. Many applications operate effectively at pressures ranging from 1,000 to 3,000 PSI. However, the specific requirements can vary widely depending on the application, with some specialized operations demanding higher pressure ratings. Selecting a pump that matches or exceeds the pressure specifications of your system can help prevent malfunctions and enhance overall reliability. Additionally, efficiency is a vital metric, as hydraulic pumps are often the heart of a hydraulic system. An efficient pump, which can operate with minimal energy loss, not only saves on operational costs but also supports a sustainable approach to hydraulic machinery management, as highlighted in recent studies indicating that efficiency improvements can reduce power consumption by up to 30%.

Common Types of Hydraulic Oil Pumps and Their Applications

When selecting a hydraulic oil pump, understanding the common types and their applications is crucial for meeting specific operational needs. One of the most prevalent types is the gear pump, renowned for its simplicity and durability. Gear pumps operate by trapping oil between two gears and forcing it through the discharge outlet, making them ideal for low-pressure applications such as lubrication systems or fuel transfer. Their robust design means they can handle various fluids, making them a versatile choice in industries like automotive and manufacturing.

Another important type is the vane pump, which utilizes sliding vanes to create chambers of fluid that are then displaced to generate flow. These pumps are typically used in moderate-pressure scenarios and are favored for their efficiency and ability to maintain a steady flow rate. Applications include material handling and mobile equipment, where consistent operation is vital. Finally, piston pumps, known for their high efficiency and capability to generate high pressures, are often found in heavy-duty applications such as construction machinery and hydraulic presses. Each type of pump has unique characteristics that make it suitable for specific situations, underscoring the importance of understanding these differences when making a selection.

Maintenance Considerations for Optimal Hydraulic Pump Performance

Proper maintenance is crucial for ensuring optimal performance of hydraulic pumps. Regular inspections can help identify potential issues before they escalate into major problems. It is important to monitor fluid levels, checking for contamination or degradation, as degraded hydraulic oil can significantly impact pump efficiency and lifespan. Additionally, ensuring that filters are clean and appropriately sized is essential; this will maintain fluid cleanliness and prevent abrasive particles from causing wear and tear on internal components.

Moreover, keeping the hydraulic system at the right temperature is vital. Excessive heat can lead to oil breakdown, while low temperatures can cause fluid viscosity issues, affecting the pump's performance. Implementing a routine maintenance schedule that includes fluid changes, filter replacements, and temperature monitoring can dramatically extend the life of the hydraulic pump. This proactive approach not only helps in maintaining system efficiency but also minimizes unexpected downtime, ultimately leading to smoother operations in any hydraulic application.

Related Posts

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

-

How to Select the Right Hydraulic Pump for Your Project Needs