10 Essential Tips for Choosing the Right Solution Pump for Your Needs

Selecting the appropriate solution pump is a critical decision that can significantly impact the efficiency and functionality of various industrial processes. According to a report by the Global Pump Market Outlook, the demand for solution pumps is projected to grow at a CAGR of 4.9% from 2021 to 2028, driven by increased industrial activities and the need for effective fluid management. This growth underscores the importance of choosing a solution pump that not only meets operational requirements but also aligns with industry standards for performance and reliability.

In diverse sectors such as chemical processing, wastewater treatment, and manufacturing, the right solution pump facilitates optimal fluid transfer, minimizes downtime, and enhances overall productivity. Technical specifications such as flow rate, pressure rating, and material compatibility are paramount when evaluating potential options. Industry experts emphasize that thorough assessment and understanding of specific application needs are essential during the selection process, as improper choice can lead to operational inefficiencies and increased costs. With the right knowledge and approach, selecting a solution pump can become a streamlined process that yields substantial long-term benefits.

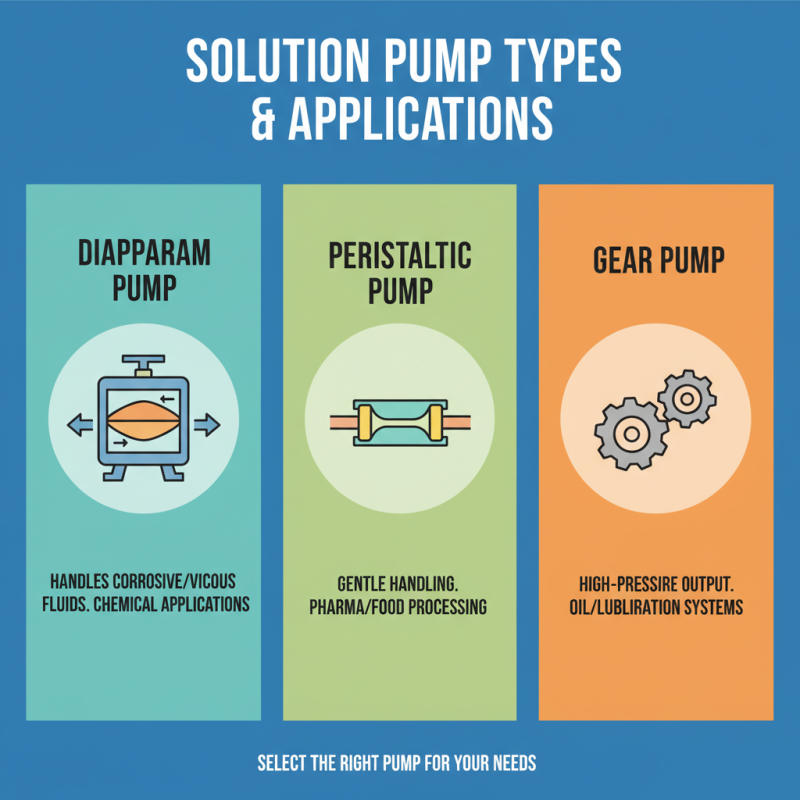

Understanding the Different Types of Solution Pumps Available

When selecting a solution pump, understanding the different types available is crucial to ensuring it meets your specific needs. Solution pumps can be categorized into several types, such as diaphragm pumps, peristaltic pumps, and gear pumps. Diaphragm pumps are known for their ability to handle corrosive and viscous fluids, making them ideal for chemical applications. On the other hand, peristaltic pumps offer gentle handling of delicate fluids, often used in pharmaceutical and food processing industries. Gear pumps excel in delivering high-pressure outputs and are commonly used in oil and lubrication systems.

When choosing a solution pump, consider the fluid characteristics, such as viscosity and chemical composition, as these factors significantly influence pump performance. It's essential to match the pump type with the specific requirements of your application. Additionally, think about the required flow rate and operating pressure, as these parameters will help narrow down your options effectively.

Another vital tip is to assess the maintenance requirements of the pump you are considering. Some designs may necessitate more frequent upkeep than others, which can affect your operational efficiency. Opting for a pump with user-friendly maintenance can save both time and resources down the line. Taking these factors into account will guide you to a solution pump that aligns perfectly with your operational needs.

Key Factors to Consider When Selecting a Solution Pump

When selecting a solution pump, several key factors come into play to ensure that the pump meets your specific needs. First, consider the type of fluid you will be pumping. The viscosity, temperature, and chemical compatibility of the solution are critical in determining the appropriate materials and design of the pump. For instance, handling corrosive substances may require materials that resist wear and degradation, while high viscosity fluids may necessitate a pump with greater suction and delivery capabilities.

Another important factor is the required flow rate and pressure. Different applications require different flow capacities, and selecting a pump that can deliver the right pressure without overexerting itself is crucial for optimal operation. Additionally, consider the pump's energy efficiency and maintenance needs, as these can affect long-term operational costs. Finally, the installation space and accessibility for maintenance should also be factored in, ensuring that the pump can be easily integrated into existing systems without causing complications. Taking these considerations into account will lead to a more informed and successful selection of a solution pump tailored to your requirements.

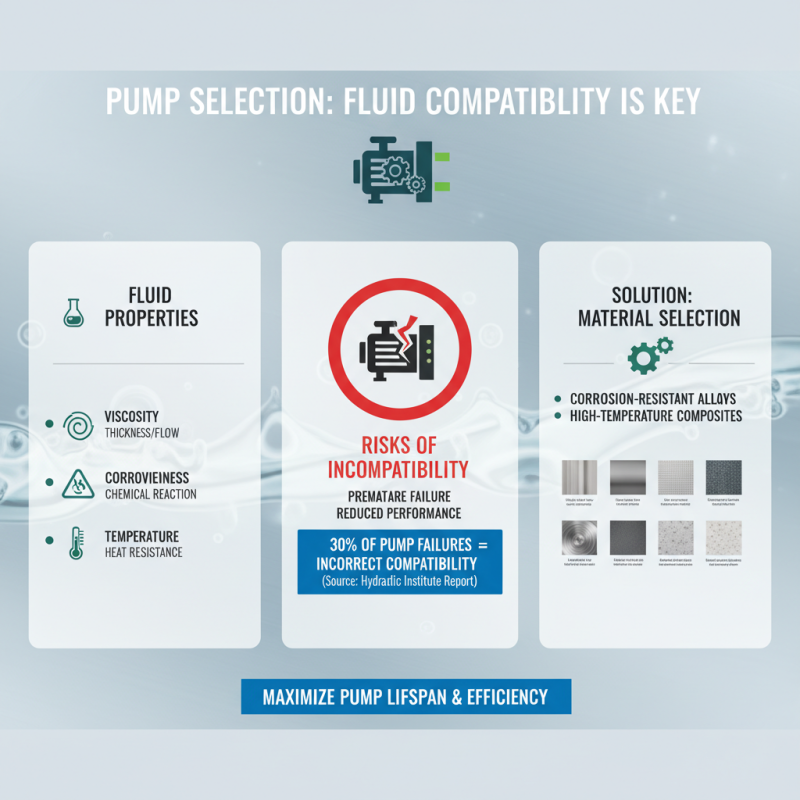

Assessing Compatibility with Your Specific Fluid Requirements

When selecting a solution pump, evaluating compatibility with your specific fluid requirements is crucial. Fluid properties such as viscosity, corrosiveness, and temperature can significantly impact pump performance and longevity. According to a recent industry report by the Hydraulic Institute, nearly 30% of pump failures can be attributed to incorrect fluid compatibility. A thorough assessment of your fluid's characteristics will help you choose the right materials for the pump components, ensuring that they can withstand the corrosive effects of certain chemicals or high-temperature conditions.

In addition to fluid compatibility, it's essential to consider the flow rate and pressure requirements specific to your application. A study from the Pump Systems Matter initiative highlighted that pumps operating at less than optimal flow conditions can lead to inefficiencies, causing up to a 15% increase in energy consumption. This not only affects your operational costs but can also lead to premature wear and tear on the pump. By understanding your fluid dynamics and specific application needs, you can select a solution pump that maximizes efficiency and minimizes maintenance costs, ultimately prolonging the operational lifespan of your equipment.

Evaluating Performance Metrics for Optimal Efficiency

When selecting the right solution pump, evaluating performance metrics is crucial for ensuring optimal efficiency. Key performance indicators such as flow rate, pressure, and power consumption should guide your decision-making process. Understanding these metrics helps you compare different pump options and select one that meets your specific requirements without wasting energy or resources.

One important tip is to assess the flow rate required for your application. This measurement indicates the volume of liquid the pump can move per unit of time and is essential for ensuring that your system operates smoothly. In addition, you should consider the pressure rating of the pump; it determines how well the pump can handle the demands of the system it will be integrated with. Finally, evaluating the energy consumption of the pump will help you understand its operational cost and efficiency over time, allowing you to make a more informed choice.

Another critical aspect to consider is the maintenance and durability of the pump. Look for models that offer easy access to components for repairs and check the materials used in construction to ensure longevity. Regular maintenance is vital for maintaining performance metrics, so choosing a pump that is designed for straightforward upkeep can save you time and resources in the long run. By focusing on these performance metrics and tips, you can select a solution pump that aligns perfectly with your operational needs.

Performance Metrics of Solution Pumps

Maintenance and Support Considerations for Long-Term Use

When choosing a solution pump, maintenance and support are vital for ensuring long-term effectiveness and reliability. According to industry reports, proper maintenance can extend the life of a pump by up to 50%, significantly reducing replacement costs. Therefore, it is imperative to consider the level of support offered by the manufacturer, including warranty terms, availability of replacement parts, and customer service responsiveness. Ensure that you pick a solution pump from a manufacturer known for strong after-sales support.

Additionally, implementing a regular maintenance schedule is crucial. This should include routine inspections, cleaning, and lubrication to address wear and tear. A study from the Hydraulic Institute highlights that proactive maintenance can cut downtime by 30% and improve operational efficiency. Many pumps can have their service intervals extended through predictive maintenance practices, which leverage data analysis to forecast potential issues before they arise.

When selecting a pump, consider the ease of maintenance as part of your evaluation. For instance, look for models that allow for easy access to vital components. Not only does this streamline your maintenance routines, but it can also minimize disruptions to operations. Always ask about the recommended maintenance practices for the pump you are considering to ensure that it aligns with your operational capabilities.

10 Essential Tips for Choosing the Right Solution Pump for Your Needs - Maintenance and Support Considerations for Long-Term Use

| Tip No. | Tip | Key Considerations | Maintenance Frequency |

|---|---|---|---|

| 1 | Identify Your Needs | Understand the flow rate and pressure requirements. | Every Use |

| 2 | Evaluate Power Source | Choose between electric and manual pumps based on application. | Monthly |

| 3 | Consider Material Compatibility | Ensure materials are suitable for the fluids being pumped. | Quarterly |

| 4 | Check for Certifications | Look for industry certifications for safety and performance. | Annually |

| 5 | Review Warranty Options | Understand coverage provided in case of failure. | N/A |

| 6 | Assess Brand Reputation | Research customer reviews and experiences. | N/A |

| 7 | Consider Size and Weight | Ensure the pump fits your installation space. | Every Use |

| 8 | Plan for Accessibility | Ensure easy access for repairs and maintenance. | Monthly |

| 9 | Evaluate Cost of Ownership | Consider initial cost, maintenance, and operating expenses. | Annual Review |

| 10 | Seek Professional Advice | Consult with experts to ensure optimal choice. | As Needed |

Related Posts

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry

-

How to Choose the Right Well Pump for Your Water Needs

-

Understanding the Benefits of a Well Pressure Pump for Your Home Water Supply

-

Top 2025 Water Well Pump Guide for Homeowners and Professionals

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump