What is a Flow Jet Pump and How Does It Work?

In the world of fluid dynamics, a flow jet pump stands out for its efficiency and versatility. Renowned expert Dr. Emily Waters once stated, "Flow jet pumps are remarkable in their ability to create pressure without the need for moving parts." This simplicity makes them valuable in various applications, from agriculture to industrial processes.

A flow jet pump operates by utilizing the energy from a high-velocity fluid, typically water, to create suction. This process allows for the lifting and transferring of another fluid efficiently. Unlike traditional pumps, flow jet pumps require minimal maintenance due to their lack of mechanical components.

However, there are limitations. The efficiency of a flow jet pump can decrease in certain environments. For example, they may struggle with highly viscous fluids. Understanding these nuances is essential for optimizing their use. Despite these challenges, the potential of flow jet pumps continues to inspire innovation and growth in the industry.

What is a Flow Jet Pump?

A flow jet pump is a fascinating device often used in various applications. Essentially, it utilizes the principle of a jet to create a vacuum, drawing fluid from a source. The core component is a nozzle that accelerates the flow of fluid to generate low pressure. This low pressure then pulls in more fluid from surrounding areas. It's a simple yet effective way to move liquids.

In practice, flow jet pumps can be quite versatile. They find uses in water treatment, aquaculture, and even in some cooking processes. The design allows them to operate without moving parts, which can lead to less wear and tear over time. However, there can be challenges. For instance, if the source fluid is too viscous, the pump may struggle to operate efficiently. It's a reminder that while technology is powerful, it often comes with its limits.

Additionally, flow jet pumps require a steady supply of energy to maintain their functionality. If water pressure fluctuates, the pump's performance can be inconsistent. Users must regularly monitor these systems to ensure optimal operation. Visual inspections can sometimes reveal problems that are not evident at first glance. Overall, while flow jet pumps offer unique advantages, understanding their operation is crucial for effective use.

Principles of Operation of Flow Jet Pumps

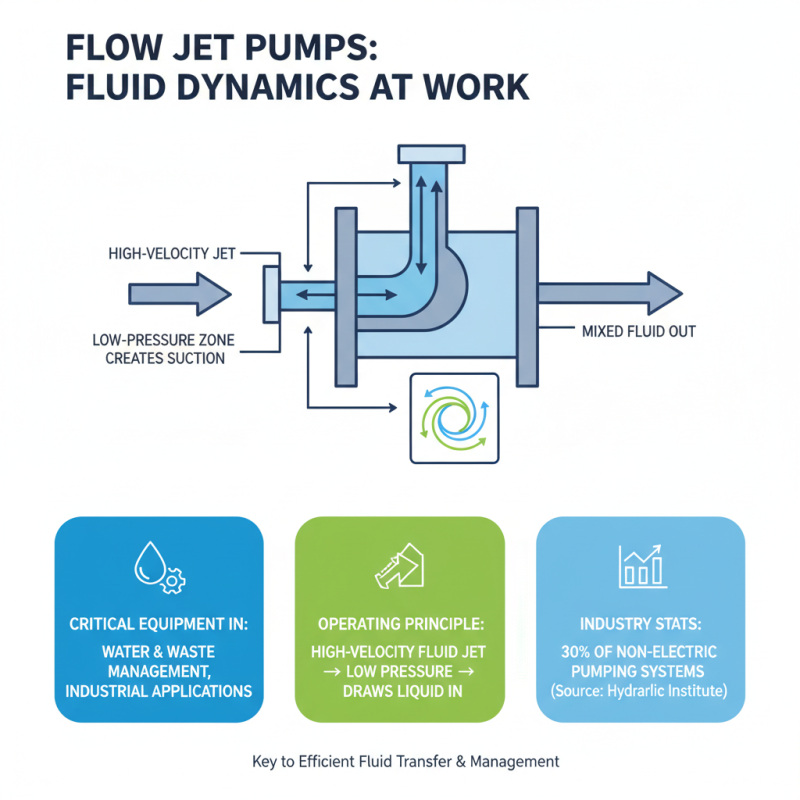

Flow jet pumps represent a critical piece of equipment in various industries, especially in water and waste management. They operate based on the principles of fluid dynamics. A flow jet pump uses a high-velocity jet of fluid to create low-pressure areas. This principle allows the pump to draw liquid into the system. According to a report from the Hydraulic Institute, jet pumps account for about 30% of non-electric pumping systems in industrial applications.

The operation of flow jet pumps relies heavily on the Venturi effect. As fluid passes through a constriction, its velocity increases while its pressure decreases. This principle creates suction, allowing additional fluid to be drawn in. It is interesting to note that flow jet pumps are designed to handle varying fluid viscosities. However, efficiency can drop when dealing with highly viscous fluids. Research indicates that the performance can be up to 40% less with such liquids.

Many operators face challenges with the maintenance of flow jet pumps. Sediment and debris can accumulate in the system over time. This buildup can significantly reduce efficiency and increase wear on components. Industry reports suggest regular inspections can mitigate these risks, yet many facilities neglect this crucial step. Understanding these operational principles helps users better maintain their equipment, ensuring longevity and reliability.

Components of a Flow Jet Pump System

A Flow Jet Pump is an efficient device used for moving fluids. Understanding its components helps us grasp how it operates. At the core of a Flow Jet Pump system is the nozzle. This nozzle creates a high-velocity jet of fluid. It mixes the primary fluid with the secondary fluid. This mixture generates suction, drawing fluids into the pump.

Another vital component is the mixing chamber. Here, the fluid from the nozzle combines. The design of this chamber affects efficiency. If the chamber is too narrow, it may limit flow. This can be a common issue in older models. After mixing, the fluid enters the diffuser. This part helps convert velocity into pressure. Properly sized diffusers are crucial for optimal performance.

Finally, the discharge pipe transports the fluid to its destination. Any leaks or blockages can affect functionality. Regular maintenance is essential, though often overlooked. Users must be aware of these elements to ensure longevity. Understanding these components allows for better troubleshooting and improved performance.

Flow Jet Pump Performance Analysis

This chart illustrates the relationship between the flow rate and the pressure generated by a Flow Jet Pump system. The data shows how varying the flow rate affects the pressure output, demonstrating the efficiency of the pump.

Applications and Uses of Flow Jet Pumps

Flow jet pumps have gained traction across various industries due to their versatility and efficiency. These pumps utilize high-velocity fluid jets to generate suction, making them ideal for applications in water treatment and chemical processing. In the water industry, their ability to handle slurries and solids makes them valuable. Reports indicate that the global market for flow jet pumps is projected to grow at a CAGR of 5% from 2022 to 2030.

In the oil and gas sector, flow jet pumps are vital for enhancing oil recovery. The technology helps in lifting fluids from deep wells, reducing the need for more expensive mechanical pumps. According to industry sources, these pumps can improve extraction rates by up to 30%. However, operational challenges exist. The pumps require regular maintenance to ensure performance. Minerals and contaminants can wear down components over time.

In agriculture, flow jet pumps facilitate irrigation processes. They provide reliable water distribution across large fields. A recent survey found that farmers using these pumps reported a 20% increase in crop yields. Yet, the energy consumption remains a concern. Balancing efficiency and environmental impact is crucial. As industries evolve, the pursuit of sustainable solutions will shape the future of flow jet pump applications.

Advantages and Limitations of Flow Jet Pumps

Flow jet pumps are popular in many applications. They use high-velocity fluid to create suction, moving water or other liquids. However, understanding their advantages and limitations is crucial for effective use.

One significant advantage is energy efficiency. Flow jet pumps can handle different flow rates without significant losses. They require less maintenance compared to traditional pumps. This makes them cost-effective in the long run. Also, they can be easily installed, adding to their appeal for many projects.

Yet, there are limitations. Flow jet pumps can struggle with high-viscosity fluids. They may not perform well under low inlet pressures, leading to inconsistent results. The initial installation can also be complex. Some users find it challenging to assess if it's the right fit for their needs. Regular monitoring is essential to maintain performance levels.

What is a Flow Jet Pump and How Does It Work? - Advantages and Limitations of Flow Jet Pumps

| Feature | Description |

|---|---|

| Operating Principle | Utilizes high-velocity water jet to create a vacuum that draws fluid into the pump. |

| Applications | Ideal for chemical processing, wastewater management, and agricultural irrigation. |

| Advantages | Simple design, low maintenance, compact size, capable of handling solids and slurries. |

| Limitations | Lower efficiency compared to mechanical pumps, limited to certain flow rates and pressures. |

| Efficiency Range | Typically ranges from 30% to 60% depending on the design and application. |

| Maintenance Frequency | Typically requires minimal maintenance, with routine checks suggested every 6-12 months. |

Related Posts

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

Exploring Market Trends: Ultra Jet Pump Innovations at the 138th China Import and Export Fair 2025

-

Why Choose Ultra Jet Pumps for Your Water Needs and What Are Their Benefits

-

Ultimate Tips for Choosing the Right Flow Jet Pump