The Future of Oil Well Pumps Innovations and Trends Transforming the Oil Industry

As the oil industry navigates a transformative era driven by technological advancements and sustainability goals, innovations in oil well pumps are proving to be pivotal in enhancing efficiency and reducing operational costs. According to a recent report by the International Energy Agency (IEA), the global demand for oil is expected to peak by 2030, emphasizing the urgency for the industry to adopt smarter, more efficient extraction methods.

Modern oil well pumps are now leveraging advancements in digital technologies, such as IoT and AI, to optimize performance and predictive maintenance, potentially reducing downtime by up to 30%. Additionally, as environmental regulations tighten, the push for cleaner technologies in oil extraction has never been more critical. Innovations in oil well pumps not only address technical challenges but also align with the industry's shift towards sustainable practices, ensuring that oil remains a vital component of the global energy mix well into the future.

Modern oil well pumps are now leveraging advancements in digital technologies, such as IoT and AI, to optimize performance and predictive maintenance, potentially reducing downtime by up to 30%. Additionally, as environmental regulations tighten, the push for cleaner technologies in oil extraction has never been more critical. Innovations in oil well pumps not only address technical challenges but also align with the industry's shift towards sustainable practices, ensuring that oil remains a vital component of the global energy mix well into the future.

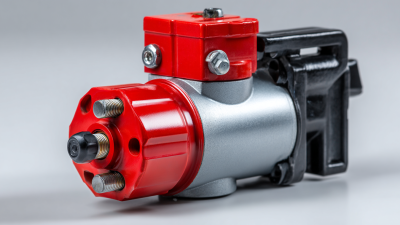

Innovations in Oil Well Pump Technology: Enhancing Efficiency and Reducing Costs

Innovations in oil well pump technology are rapidly transforming the oil industry, focusing on enhancing efficiency and reducing costs. As evidenced by recent advancements, the digital transformation within oilfields like Changqing Oilfield signifies a shift towards smarter, more effective operations. By integrating intelligent systems, companies can optimize the production cycle, maintaining well performance for extended periods and significantly reducing operational expenses. Notably, the energy consumption for certain pumping systems has been reduced by a remarkable 69.1%, demonstrating a commitment to efficiency and sustainability.

Tips: Embracing digital tools and automation in oil well management can lead to substantial cost savings and improved output. Operators should consider regular evaluations and updates of their pumping systems to incorporate these advancements, ensuring they remain competitive in a rapidly evolving market. Integrating green technologies not only aligns with global decarbonization goals but also enhances operational longevity.

With the global artificial lift systems market projected to exceed $11.6 billion by 2024, driven by exploration activities and the need for optimized production from mature fields, oil companies are compelled to adopt innovative technologies. Fostering a workforce skilled in the latest pumping technologies will be crucial for maintaining high efficiency and achieving high-quality development in the industry. Emphasizing sustainability and technological advancements will pave the way for future growth and resilience.

The Future of Oil Well Pumps Innovations and Trends Transforming the Oil Industry

| Innovation Type | Description | Benefits | Estimated Cost Reduction (%) | Implementation Year |

|---|---|---|---|---|

| Variable Frequency Drives | Allows pumps to operate at varying speeds to match production requirements. | Increases efficiency and extends equipment life. | 20% | 2022 |

| Smart Sensors | Sensors that monitor pump performance and alert for maintenance needs. | Improves uptime and reduces maintenance costs. | 15% | 2023 |

| Non-Clog Pumps | Designed with impellers that prevent clogging from solids in the fluid. | Reduces downtime caused by blockages. | 10% | 2024 |

| High-Efficiency Motors | Electric motors designed to minimize energy loss during operation. | Lower energy consumption leads to cost savings. | 25% | 2021 |

| Automatic Control Systems | Systems that automate pump operations based on real-time data. | Enhances precision in operations and reduces labor costs. | 30% | 2025 |

The Role of IoT and Data Analytics in Optimizing Oil Well Pump Operations

The oil industry is undergoing a significant transformation, driven by innovations in technology that are redefining the operations of oil well pumps. Among these innovations, the integration of the Internet of Things (IoT) and data analytics stands out as a game-changer. IoT devices are now capable of collecting real-time data directly from pump systems, enabling operators to monitor performance and detect anomalies with precision. This level of insight allows companies to optimize their operations, reducing downtime and improving the overall efficiency of oil extraction processes.

Tips: Regularly analyze the data collected from IoT devices to identify trends and anomalies. Implement predictive maintenance strategies based on this data to prevent costly breakdowns.

As data analytics continues to evolve, the potential for improving oil well pump operations only grows. Advanced algorithms can process vast amounts of data to generate actionable insights, allowing operators to make informed decisions aimed at enhancing productivity and reducing operational costs. By embracing these advanced analytics, oil companies can not only stay competitive but also maximize their resource management.

Tips: Invest in training your team to effectively interpret data analytics reports. This ensures that insights gained are applied in real-time to improve operational effectiveness.

Emerging Trends: Electric and Solar-Powered Pumps Revolutionizing Oil Extraction

The oil industry is undergoing a significant transformation with the emergence of electric and solar-powered pumps, setting the stage for a more sustainable future. These innovative pumping systems not only enhance the efficiency of oil extraction but also align with global efforts to reduce carbon emissions. By integrating renewable energy sources, the industry can mitigate its environmental impact, making the transition to cleaner energy more feasible.

In parallel, the agricultural sector is also embracing sustainable technologies, as seen in China’s initiative to deploy green hydrogen to reduce farming emissions. This approach underscores the importance of innovative solutions in various industries, where combining advancements like hydrogels and hydro agriculture can lead to improved efficiency. As industries converge towards sustainability, it becomes evident that the future of oil extraction will increasingly depend on such technological integrations, ultimately driving a holistic shift towards greener energy practices.

How Predictive Maintenance is Shaping the Future of Oil Well Pump Performance

Predictive maintenance is revolutionizing the performance of oil well pumps by utilizing advanced analytics and machine learning to forecast equipment failures before they occur. According to a recent report from the International Energy Agency (IEA), predictive maintenance can reduce operational costs by up to 30% while increasing equipment uptime by as much as 20%. This proactive approach not only extends the lifespan of the pumps but also enhances the overall efficiency of oil extraction operations, which is critical in an industry facing increasing demand and pressure for sustainability.

The integration of the Internet of Things (IoT) and real-time data analytics in oil well pump management allows operators to monitor performance continuously and make informed decisions swiftly. A study by Deloitte highlighted that companies adopting predictive maintenance strategies experienced a 25% reduction in downtime. As competition grows, the implementation of such innovative technologies will be essential for oil companies aiming to optimize production and minimize costs, while also addressing the environmental concerns linked to oil extraction practices. With the ongoing advancement in these technologies, the future of oil well pumps seems poised for significant improvements in both productivity and sustainability.

Regulatory Impacts on Oil Pump Innovations: Navigating Environmental Challenges

As the oil industry continues to evolve, regulatory impacts play a significant role in shaping innovations in oil well pumps. With increasing environmental concerns, companies must navigate a complex landscape of regulations that aim to minimize ecological footprints while maximizing extraction efficiency. This shift has catalyzed the development of advanced pumping technologies that not only comply with environmental guidelines but also enhance operational effectiveness.

**Tips:** To align with regulatory requirements, consider investing in digital monitoring systems. These can provide real-time data on emissions and performance, ensuring compliance while also identifying areas for improvement. Additionally, adopting energy-efficient pump designs can significantly reduce overall energy consumption.

Moreover, public scrutiny and the demand for sustainable practices are pushing the oil sector towards innovations that reflect environmental responsibility. Innovations such as solar-powered pumps and automated systems that reduce human intervention are gaining traction. These technologies not only help meet regulations but also improve safety and reduce operational costs.

**Tips:** Stay informed about local and global environmental regulations, as they can influence the acceptance and funding of new technologies. Regular training for staff on compliance and best practices can also enhance both safety and efficiency in pump operations.

The Future of Oil Well Pumps: Innovations and Trends Transforming the Oil Industry

This chart illustrates the projected market growth rates of various innovative oil well pump technologies. As the oil industry evolves, advancements such as electric and solar-powered pumps are gaining traction, emphasizing the importance of smart technologies and environmental considerations in future developments.

Related Posts

-

Understanding the Role of Fracking Pumps in Modern Oil Extraction Techniques

-

5 Essential Tips for Choosing the Right Surface Jet Pump for Your Needs

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

How to Choose the Right Solution Pump for Your Business Needs

-

Ultimate Guide to Fracking Pump Maintenance Checklist for Optimal Performance