Why Do Gas Well Pumps Fail and How to Ensure Your Pump's Longevity?

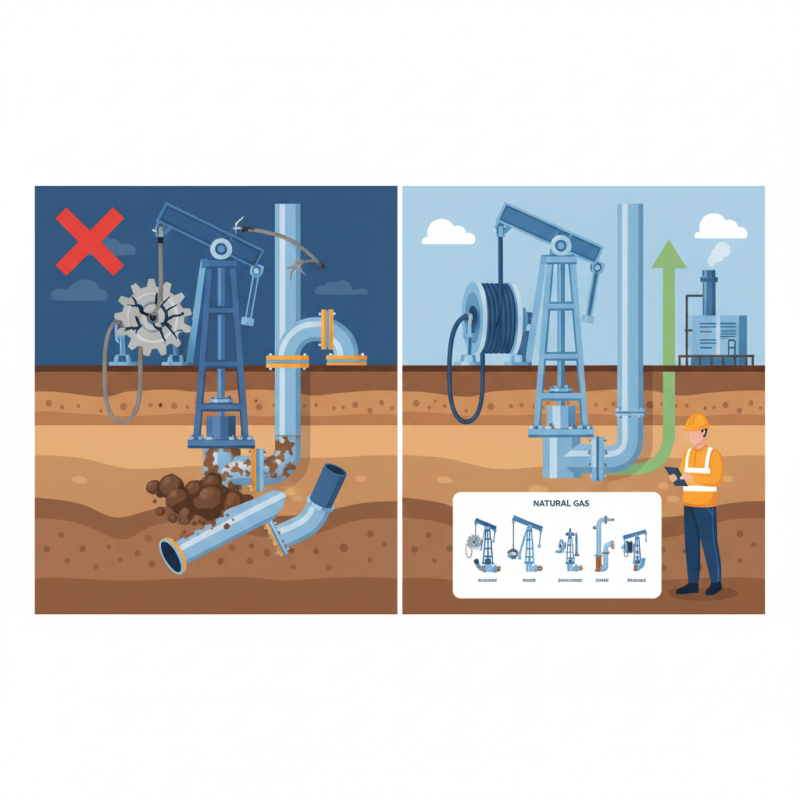

Gas well pumps play a crucial role in the extraction of natural gas, facilitating the movement of gas from underground reserves to the surface. However, understanding why gas well pumps fail is vital for maintaining efficiency and ensuring longevity. The failure of these pumps can stem from various factors, including mechanical wear and tear, improper installation, and environmental changes. Recognizing these potential pitfalls is essential for operators aiming to prolong the life of their equipment and minimize operational downtime.

To enhance the reliability of gas well pumps, careful attention to maintenance protocols and regular inspections is indispensable. Operators must implement a systematic approach to monitor the health of their pumps, addressing any signs of wear promptly. Additionally, selecting the right pump for specific well conditions can significantly influence performance and durability. By understanding the common failure modes and taking proactive measures, operators can not only protect their investments but also optimize the overall efficiency of gas extraction processes. In this article, we will explore the reasons behind gas well pump failures and outline effective strategies to ensure their longevity.

Understanding the Common Causes of Gas Well Pump Failures

Gas well pumps are critical components in the extraction of natural gas, yet they are often subject to failures that can halt production and result in costly repairs. Understanding the common causes of these failures is essential for operators looking to ensure the longevity of their pumps. One of the leading causes of pump failure is the accumulation of debris or sediment in the well. This can lead to blockages, decreased efficiency, and increased wear on pump components. Additionally, improper installation or misalignment of the pump can create undue strain, resulting in premature failure.

Regular maintenance is key to avoiding these common pitfalls. Tips for maintaining the longevity of your gas well pump include conducting routine inspections to identify signs of wear and tear early, ensuring that the pump is properly aligned during installation, and implementing a cleaning schedule to remove any sediment buildup. Operators should also keep an eye on fluid levels and ensure that the pump is not operating under extreme conditions, as this can lead to overheating and subsequent failure.

Another important aspect is the monitoring of operational parameters. Understanding how your pump performs under various conditions can help you detect inefficiencies before they lead to failure. Keeping detailed records and performing trend analysis can provide insights into potential issues, allowing for preemptive action to maintain pump health and longevity.

Identifying Warning Signs of Potential Pump Malfunctions

Identifying warning signs of potential pump malfunctions is crucial for the longevity of gas well pumps. According to the American Petroleum Institute (API), approximately 15% of all pump failures can be attributed to improper maintenance and neglecting early warning indicators. Common signs of potential issues include unusual vibrations, changes in pump noise, and fluctuations in pressure or flow rates. Regular monitoring of these parameters can help in early detection and intervention, preventing more significant problems down the line.

Moreover, the U.S. Department of Energy reports that nearly 30% of all pump failures are linked to seal and bearing wear, which can often be identified through increased heat generation and abnormal fluid leaks. Keeping an eye on these factors and scheduling routine maintenance can significantly reduce unexpected downtimes and extend the operational life of the pump. Implementing a predictive maintenance strategy based on real-time data collection can also enhance pump reliability, ultimately leading to a more efficient gas extraction process while minimizing operational costs.

Gas Well Pump Failure Causes and Longevity Tips

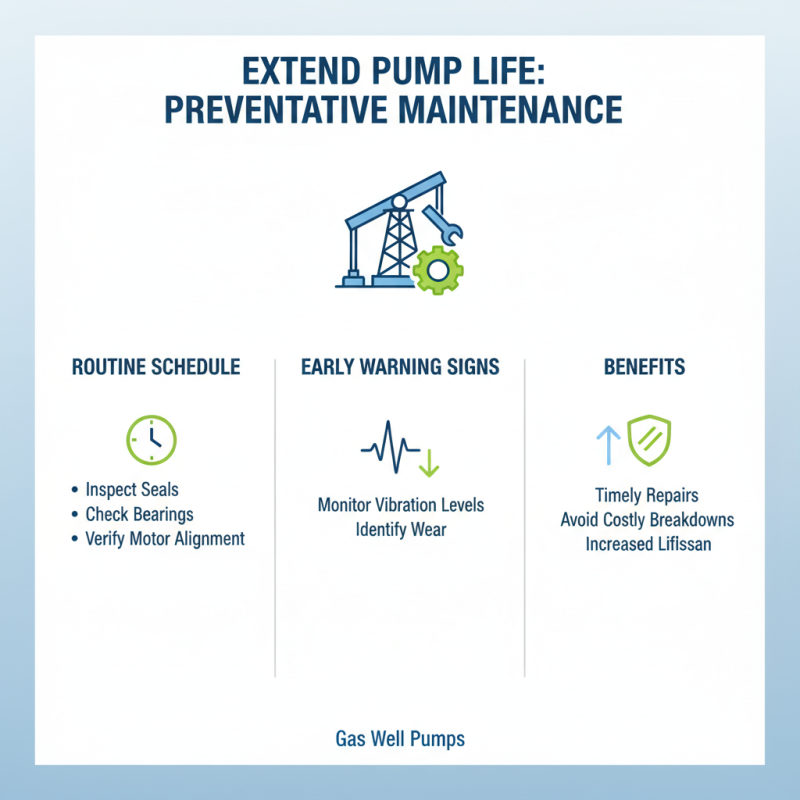

Preventive Maintenance Practices for Enhanced Pump Longevity

Preventive maintenance is crucial in extending the lifespan of gas well pumps. Regular inspection and timely repairs can help identify potential issues before they escalate into major failures. Operators should establish a routine maintenance schedule that includes checking seals, bearings, and motor alignment, as these components are often the first to show signs of wear. Additionally, monitoring vibration levels can provide early warnings of mechanical problems, allowing for corrective actions to be taken before costly breakdowns occur.

Tips for maintaining pump health include keeping detailed logs of maintenance activities and performance metrics. This documentation can reveal patterns in pump behavior and assist in scheduling future maintenance more effectively. Another practical tip is to ensure that all personnel involved in pump operation and maintenance are well-trained, as human error can also lead to premature pump failure. By promoting a culture of safety and diligence, operators can significantly enhance the reliability of their gas well pumps.

Furthermore, it's essential to maintain a clean operating environment. Dust, dirt, and debris can cause wear and tear over time, so investing in protective equipment, such as covers and filters, helps mitigate these risks. Regularly cleaning the surrounding area and ensuring proper drainage can also prevent water accumulation, which could lead to corrosion or electrical failures. By focusing on these preventive maintenance practices, operators can maximize their pump's longevity and efficiency.

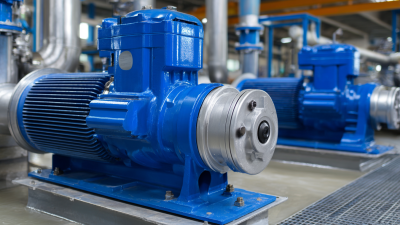

Choosing the Right Equipment for Optimal Performance

Selecting the right equipment for gas well pumps is crucial for ensuring optimal performance and longevity. According to a report from the American Petroleum Institute, improper selection and installation of pump systems can lead to a staggering 30% of failures in the field. When choosing a pump, factors such as flow rate, pressure, and the specific characteristics of the well must be carefully considered. For instance, using a pump that is not designed to handle the specific fluid characteristics—such as viscosity and gas-to-liquid ratio—can lead to inefficiencies and mechanical failures over time.

Moreover, regular maintenance and monitoring of pump performance can significantly enhance the lifespan of the equipment. The Gas Technology Institute highlights that routine inspections and the integration of predictive maintenance technology can reduce unexpected downtime by up to 20%. Employing advanced analytics can provide insights into pump operating conditions, allowing operators to make informed decisions on maintenance schedules and potential upgrades. By prioritizing the right initial equipment selection and ongoing maintenance strategies, operators can not only improve the operational efficiency but also maximize the longevity of their gas well pumps, thereby ensuring a more reliable and economical energy production process.

The Role of Regular Inspections in Pump Reliability and Efficiency

Regular inspections play a pivotal role in ensuring the reliability and efficiency of gas well pumps. According to a report by the American Petroleum Institute, improper maintenance leads to more than 30% of pump failures within the oil and gas industry. These failures can be attributed to a range of issues including wear and tear, inadequate lubrication, and contamination from debris. Regular inspections can identify these issues early, allowing for timely interventions that can extend the lifespan of a pump.

To maintain pump efficiency, operators should implement a routine inspection schedule that includes checking pressure levels, fluid quality, and mechanical components. It’s recommended to conduct these checks at least once a month, or more frequently during peak production periods. Utilize vibration analysis and thermal imaging to detect potential problems before they progress into more serious failures.

**Tips:** Always keep a detailed log of inspection results to track performance trends over time. This data can help predict when maintenance is needed, reducing unplanned downtimes. Furthermore, training personnel to recognize signs of wear and performance degradation can empower teams to act before issues escalate. By prioritizing regular inspections, operators not only enhance reliability but also contribute to overall operational efficiency.

Why Do Gas Well Pumps Fail and How to Ensure Your Pump's Longevity? - The Role of Regular Inspections in Pump Reliability and Efficiency

| Inspection Frequency (Weeks) | Common Failure Causes | Impact on Performance (%) | Recommended Action | Expected Longevity Increase (Years) |

|---|---|---|---|---|

| 2 | Wear and Tear | 15 | Replace worn components | 1-2 |

| 4 | Corrosion | 20 | Inspect and treat for corrosion | 2-3 |

| 6 | Overheating | 25 | Ensure proper cooling systems are in place | 3-5 |

| 8 | Mechanical Failure | 30 | Conduct regular maintenance checks | 4-6 |

Related Posts

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry

-

2025 Top 5 Industrial Pumps: Best Picks for Efficiency and Performance

-

Top 5 Oil Well Pumps to Maximize Efficiency and Reduce Costs in 2023

-

How to Select the Right Fracking Pump for Your Oil and Gas Operations

-

How to Choose the Right Water Well Pressure Pump for Your Needs

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump