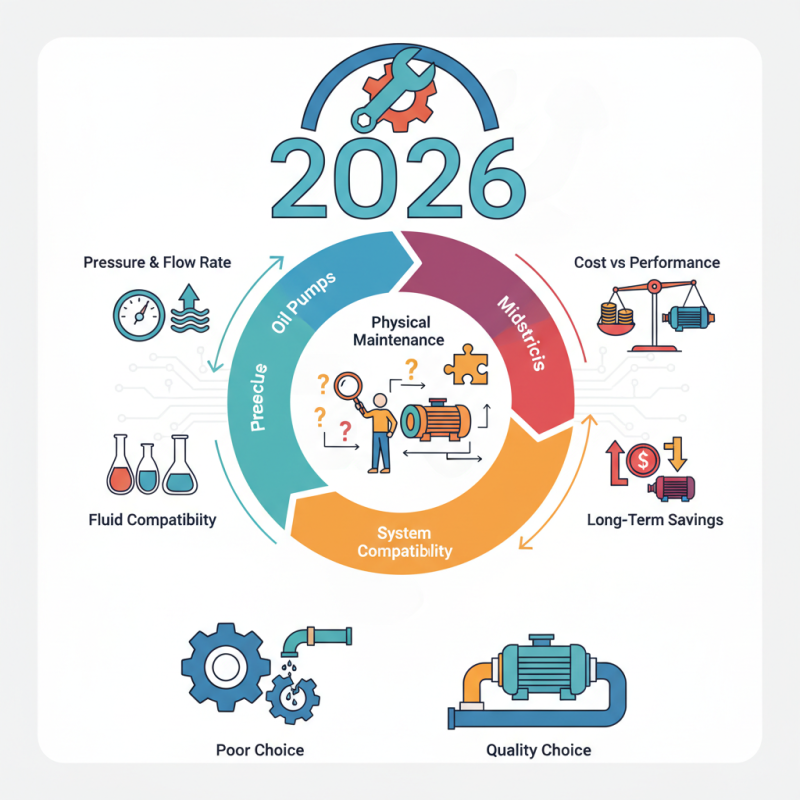

2026 How to Choose the Right Hydraulic Oil Pump for Your Needs?

Choosing the right hydraulic oil pump requires careful consideration. According to John Smith, a leading expert in hydraulic technology, "Selecting the correct pump can significantly impact operational efficiency." His insight emphasizes the importance of this decision.

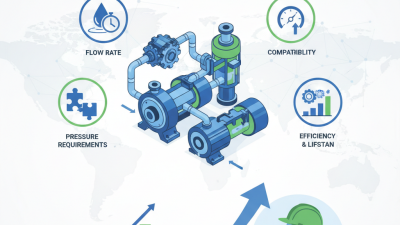

Hydraulic oil pumps come in various types. Each type serves different applications. Factors such as pressure, flow rate, and compatibility with hydraulic fluids should guide your choice. A pump that works well in one scenario may fail in another. Many users find themselves overwhelmed by choices.

Physical maintenance and compatibility must be reflected upon. A poorly chosen hydraulic oil pump can lead to leaks or inefficiencies. Evaluating your specific needs is crucial. Always remember that quality pumps may have higher initial costs. However, they often save money in the long run. It’s a challenging balance between price and performance.

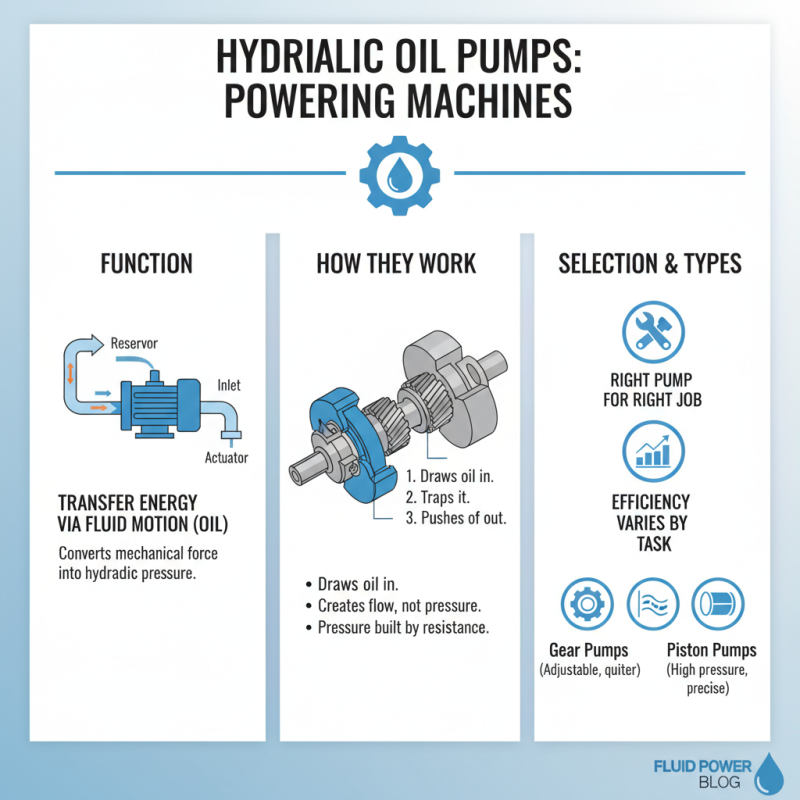

Understanding the Basics of Hydraulic Oil Pumps

Hydraulic oil pumps are crucial in various machines. They transfer energy through fluid movement. Understanding how they work is key to selecting the right one. Different applications require different types of pumps. Some can be more efficient than others, depending on the specific task at hand.

When choosing a pump, consider flow rate and pressure. Matching these specifications to your needs is vital. An oversized pump can lead to wasteful energy consumption. Conversely, an undersized pump may not perform efficiently. It's essential to evaluate the environment and heat generation too. A pump that runs too hot can fail prematurely, costing you in repairs.

Look into the material and build quality. Some pumps handle certain fluids better than others. Know your fluid’s viscosity. This can affect the pump's performance. Don’t overlook compatibility with other system components. Each system is unique, which means there is no one-size-fits-all solution. Engage with experts when unsure. They can provide insights that may clarify your choices.

Types of Hydraulic Oil Pumps and Their Applications

Hydraulic oil pumps come in various types, each suited to different applications. Gear pumps are simple and reliable. They create flow by rotating gears within a casing. These pumps are often used in manufacturing and automotive industries. They work well for moderate pressure and flow requirements. However, they may not be suitable for extreme conditions.

Piston pumps provide higher pressure and flow rates. They use pistons to create hydraulic power. These pumps are commonly found in construction machinery and heavy equipment. They are efficient but can be complex to maintain. Proper care is essential to avoid failures. Vane pumps, on the other hand, are versatile and can operate smoothly across a range of fluids. They are widely used in hydraulic systems where space is limited.

Choosing the right pump involves understanding your specific needs. Consider factors like pressure, flow rate, and fluid compatibility. Overlooking these details can lead to inefficiencies. It is important to assess the operational environment and potential challenges. Ensuring the right match can prevent costly mistakes and enhance performance.

2026 How to Choose the Right Hydraulic Oil Pump for Your Needs? - Types of Hydraulic Oil Pumps and Their Applications

| Pump Type | Key Features | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Gear Pump | Simple design, fixed displacement | Excavators, forklifts | Durable, cost-effective | Less efficient at varying loads |

| Vane Pump | Variable displacement, smooth operation | Industrial machinery, automotive | Good efficiency, quiet operation | Wear over time, limited suction |

| Piston Pump | High pressure, adjustable displacement | Heavy equipment, mobile machines | High efficiency, versatile | Complex design, higher cost |

| Diaphragm Pump | Sealed with a diaphragm, self-priming | Chemical transfer, food industry | Ability to handle viscous fluids, minimal leakage | Lower flow rates, limited pressure |

Key Factors to Consider When Selecting a Hydraulic Pump

Choosing the right hydraulic oil pump is crucial for efficiency. Several key factors can help guide this decision. First, consider the flow rate required for your application. This is usually measured in gallons per minute (GPM) or liters per minute (LPM).

Next, take into account the pressure rating of the pump. Different applications require different pressure levels. A pump that cannot meet these needs may lead to performance issues. Remember to also look at the pump's material and construction. Some materials handle certain fluids better than others.

Tips: Always check the compatibility of the pump with your hydraulic fluid. This can prevent damage and ensure longevity. Make sure to consider space. Dimensions can be limiting in certain setups.

Lastly, think about maintenance. Some pumps require more upkeep than others. Reflect on how often you can maintain the equipment. It’s better to choose a pump that aligns with your maintenance capabilities. Balancing these factors will help you make a more informed decision.

Compatibility of Hydraulic Oil with Pump Components

When selecting a hydraulic oil pump, compatibility with the hydraulic oil is crucial. The oil needs to be suitable for the materials used in the pump. Common materials include aluminum, steel, and various plastics. Each material interacts differently with specific oils, which affects performance and longevity. For instance, some oils can cause swelling in certain rubber seals. This can lead to leaks, which disrupt operation.

Before making a choice, identify the pump components. Check the specifications for materials and ensure you understand the oil's formulation. The viscosity of hydraulic oil also plays a vital role. If the viscosity is not aligned with the pump’s requirements, efficiency decreases. This can result in overheating and eventual failure.

It’s essential to conduct tests on compatibility. Sometimes, the oils may appear suitable but can cause problems over time. Lubrication properties vary widely. Even minor discrepancies can lead to significant complications. Ignoring these factors could lead to costly mistakes. Keeping a close eye on the interactions between oil and pump materials is not just smart; it’s necessary for sustainable operation.

Maintenance Tips for Maximizing Hydraulic Pump Performance

Maintaining a hydraulic pump is crucial for optimal performance. Regular inspections can help identify potential issues early. Industry reports suggest that nearly 30% of hydraulic pump failures are due to improper maintenance. Checking fluid levels regularly can prevent serious problems. Always ensure filters are clean and free from debris. A clogged filter can lead to reduced efficiency.

Temperature control is vital. Overheating can cause significant damage. Maintaining the oil at recommended temperatures extends pump lifespan. Studies have shown that consistent temperature maintenance can increase a pump's operational life by up to 20%. Moreover, analyzing oil condition is important. Fluid analysis can reveal contaminants before they cause damage.

Incorporating these practices is often overlooked. Many operators think that a quick visual check is sufficient. However, this can lead to costly repairs down the line. Routinely checking seals and connections can prevent leaks. Leaks are not just wasteful; they indicate deeper issues within the system. It's essential to stay proactive in maintenance efforts. Proper attention can save both time and money.

2026 How to Choose the Right Hydraulic Oil Pump for Your Needs?

Related Posts

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

7 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

-

How to Select the Right Hydraulic Pump for Your Project Needs

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

How to Optimize Production with Artificial Lift Pumps: Enhancing Efficiency in Oil Wells

-

How to Optimize Oilfield Jet Pump Efficiency: Tips & Industry Insights