What is a Hydraulic Gas Pump and How Does It Work?

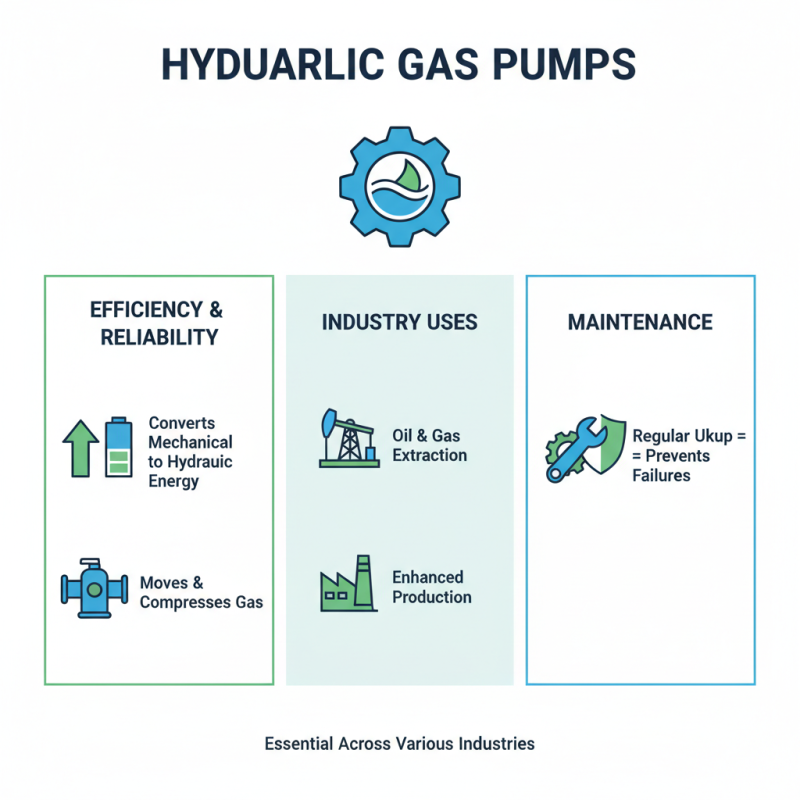

Hydraulic gas pumps are essential in various industrial applications. They provide reliable energy transfer and are critical for operations in sectors like oil and gas. According to a report by Market Research Future, the hydraulic pump market is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth highlights the increasing reliance on hydraulic systems.

Dr. Emily Carson, a leading expert in hydraulic systems, states, “Hydraulic gas pumps are vital for ensuring efficient energy usage.” This emphasizes the importance of these pumps in maintaining performance in challenging conditions. However, many industries overlook regular maintenance of hydraulic gas pumps, risking inefficiency and potential failures.

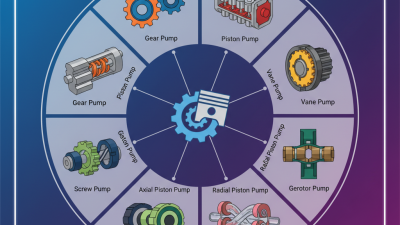

Addressing common misconceptions about hydraulic gas pumps is crucial. Some mistakenly believe that all pumps are interchangeable. Each pump serves specific functions, and incorrect usage can lead to operational setbacks. The complexities of hydraulic systems should not be underestimated. Understanding them is essential for optimizing performance and minimizing downtime.

What is a Hydraulic Gas Pump? Definition and Overview

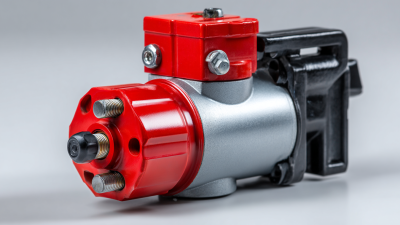

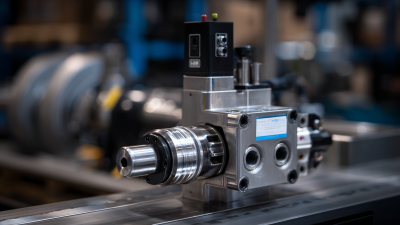

A hydraulic gas pump is a fascinating device used in various industries. It converts gas energy into hydraulic energy. This process helps in power transmission and fluid movement. Hydraulic gas pumps are efficient and reliable for many applications. They are particularly useful in heavy machinery and systems requiring high pressure.

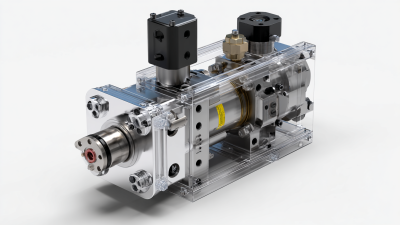

The working mechanism of a hydraulic gas pump is intriguing. It typically employs a piston and cylinder system. When gas enters the pump, it pushes the piston, creating pressure. This pressure then drives hydraulic fluid through the system. The flow of hydraulic fluid enables machines to perform tasks, such as lifting or moving heavy loads. However, the efficiency can vary based on several factors, including system design and maintenance.

Some challenges can arise with hydraulic gas pumps. Wear and tear on pistons may lead to leaks. These leaks can reduce overall efficiency. Additionally, fluctuations in gas availability can impact performance. Regular inspection and maintenance are crucial to ensure smooth operation. Customers often overlook this, which can lead to unexpected downtime. It's essential to balance performance with appropriate usage and care.

Hydraulic Gas Pump Efficiency Data

This chart displays the efficiency of different hydraulic gas pumps at varying pressures. The data demonstrates how efficiency changes with pressure settings, showcasing the performance range of hydraulic gas pumps.

Key Components of a Hydraulic Gas Pump Explained

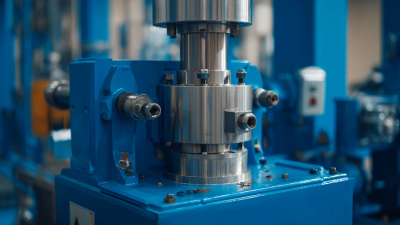

A hydraulic gas pump is crucial in various industries, including oil and gas. Understanding its components can enhance efficiency and reduce downtime.

One key component is the hydraulic cylinder. It converts hydraulic energy into mechanical energy. Typically, these cylinders are designed to withstand high pressures. Reports indicate that they can operate effectively under pressures exceeding 3,000 psi. Regular maintenance of these cylinders can significantly prolong their lifespan.

Another important element is the hydraulic accumulator. This device stores energy and helps maintain consistent pressure. It ensures that the pump can operate smoothly, even during peak demand. Industry data suggests that properly sized accumulators can improve system efficiency by up to 25%.

Tip: Always monitor the pressure levels. Too much pressure can lead to equipment failure. Also, ensure that all seals and connections are intact. Any leak can drastically reduce performance. Regular checks can prevent potential pitfalls.

Lastly, consider the hydraulic fluid used in the system. The viscosity of hydraulic fluids affects performance. Optimal viscosity can enhance the pump's efficiency and reduce wear on components. Keeping fluid clean is also crucial for pump longevity.

Operating Principles: How Hydraulic Gas Pumps Function

Hydraulic gas pumps operate on essential principles of fluid dynamics. These pumps utilize hydraulic pressure to move gases. They convert hydraulic energy into mechanical energy using fluids to generate force. This process is vital in various sectors, particularly in the oil and gas industry, where efficiency is critical. According to industry reports, about 30% of energy loss occurs in poorly designed hydraulic systems.

Understanding the operating mechanisms is essential. Hydraulic gas pumps work by creating a low-pressure area that draws in gas, then compresses it by applying hydraulic force. A study by the American Society of Mechanical Engineers highlights that optimizing these pumps can enhance performance by up to 20%. However, frequent maintenance is often overlooked, leading to inefficiencies and increased operational costs.

Many operators underestimate the significance of hydraulic fluid selection. The wrong fluid can cause wear and tear, resulting in breakdowns. Research indicates that using high-quality fluids can reduce maintenance needs by nearly 15%. Despite this, some users still choose cheaper options, risking longevity. Balancing cost with reliability is a challenge many face in this industry.

Applications of Hydraulic Gas Pumps in Industry

Hydraulic gas pumps are widely used across various industries due to their efficiency and reliability. These pumps convert mechanical energy into hydraulic energy, allowing for the movement and compression of gas. In the oil and gas sector, hydraulic gas pumps support extraction processes. They help to move natural gas, enhancing production rates. Engineers often need to ensure these pumps are regularly maintained to prevent failures.

Manufacturing industries also leverage hydraulic gas pumps. They are essential in powering heavy machinery. The smooth operation of production lines often relies on these pumps. However, operators must monitor their performance closely. Any small malfunction can lead to significant delays in production.

Additionally, hydraulic gas pumps play a role in environmental applications. They help manage gas emissions in treatment facilities. Innovations in pump technology aim to improve energy efficiency. Yet, the balance between performance and sustainability remains a challenge. Each application presents unique issues to address.

Performance Metrics: Efficiency and Output of Hydraulic Gas Pumps

Hydraulic gas pumps are essential in various industrial applications. Their efficiency is measured through key performance metrics. The output indicates how much fluid they can move effectively. This performance can vary based on design and operational conditions.

Efficiency is vital for productivity. A pump that uses less energy while delivering high output is ideal. Many factors can affect this, including pressure levels, temperature, and fluid type. Using optimal fluids can enhance efficiency. It’s not just about power; sometimes, less is more.

**Tips:** Always consider the environment when choosing fluids. Consider seasonal changes in temperature. Regular maintenance can help optimize performance. Don't ignore small leaks; they can affect overall efficiency significantly. Keep track of output regularly; inconsistencies could indicate issues needing attention.

Performance Metrics: Efficiency and Output of Hydraulic Gas Pumps

| Pump Model | Max Output (GPM) | Efficiency (%) | Operating Pressure (PSI) | Weight (lbs) |

|---|---|---|---|---|

| Model A-300 | 50 | 85 | 1500 | 40 |

| Model B-500 | 75 | 90 | 2000 | 55 |

| Model C-450 | 60 | 88 | 1800 | 50 |

| Model D-600 | 80 | 92 | 2200 | 65 |

Related Posts

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

-

Top 2025 Hydraulic Gas Pump Trends and Innovations You Need to Know

-

Top 10 Hydraulic Oil Pump Types You Should Know?

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025