Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications

In recent years, the industrial sector has witnessed a transformative shift towards more efficient and sustainable practices, with hydraulic gas pumps leading the way. According to a report by the International Energy Agency, industrial processes account for approximately 30% of global energy consumption, making the push for innovative technologies essential for reducing emissions and optimizing productivity. Hydraulic gas pumps, leveraging the power of pressurized gases to transfer liquids, have emerged as a game-changer in various applications such as manufacturing, construction, and oil and gas extraction.

In recent years, the industrial sector has witnessed a transformative shift towards more efficient and sustainable practices, with hydraulic gas pumps leading the way. According to a report by the International Energy Agency, industrial processes account for approximately 30% of global energy consumption, making the push for innovative technologies essential for reducing emissions and optimizing productivity. Hydraulic gas pumps, leveraging the power of pressurized gases to transfer liquids, have emerged as a game-changer in various applications such as manufacturing, construction, and oil and gas extraction.

By enhancing performance while reducing operational costs, these pumps are not only proving to be vital in increasing system efficiency but also in minimizing environmental impact. As industries strive towards achieving heightened efficiency and sustainability, the adoption of hydraulic gas pumps is anticipated to substantially shape future industrial applications.

Advantages of Hydraulic Gas Pumps in Industrial Processes

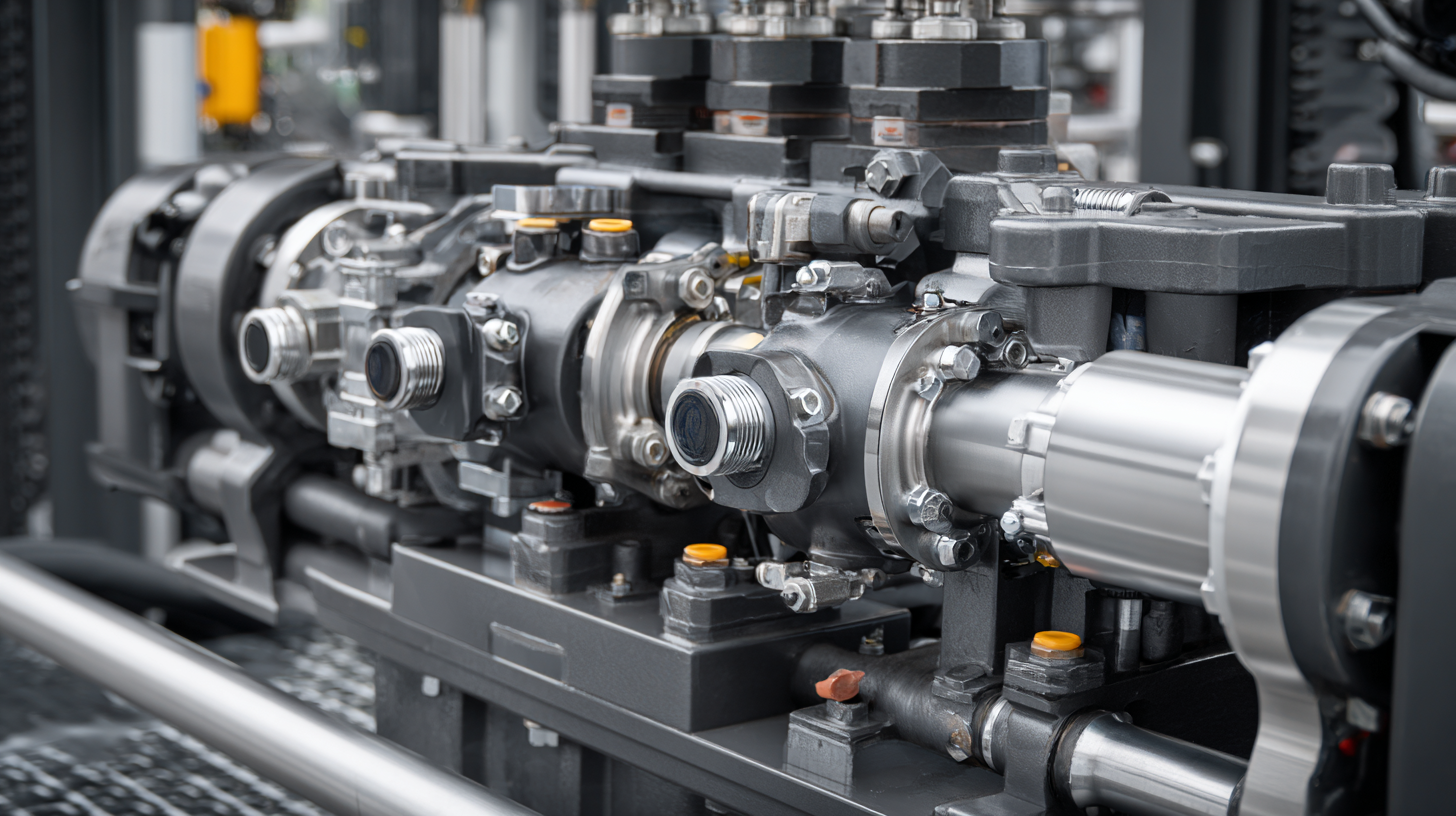

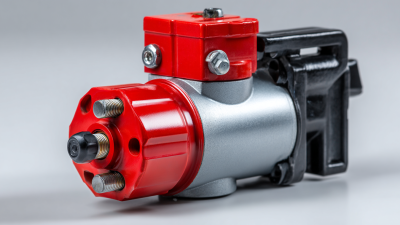

Hydraulic gas pumps have emerged as a transformative force in industrial applications, offering a range of advantages that significantly enhance operational efficiency. According to a recent report by the International Journal of Engineering, hydraulic pumps can increase the efficiency of power transmission by up to 30%, making them an attractive option for industries looking to optimize performance. Their ability to operate at high pressures allows for more compact designs, reducing space requirements in facilities without compromising power output.

Furthermore, the durability and reliability of hydraulic gas pumps are noteworthy; the American Society of Mechanical Engineers (ASME) estimates that these pumps can reduce maintenance costs by as much as 20% compared to traditional mechanical systems. This is largely due to their ability to handle various fluid viscosities and their resistance to wear from contaminants, which are common challenges in industrial settings. As industries increasingly adopt automation and advanced processes, the efficiency gains from hydraulic gas pumps position them as a pivotal component in modern manufacturing and processing operations.

Key Industries Transforming Operations with Hydraulic Technology

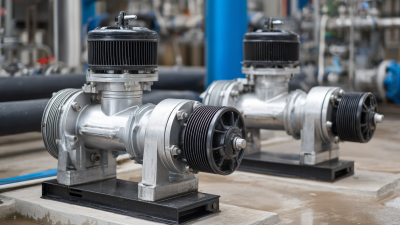

Hydraulic gas pumps are increasingly becoming indispensable in various key industries, revolutionizing operational efficiency and productivity. In manufacturing, for instance, these pumps facilitate the automation of processes, allowing for precise control of machinery and reducing the risk of human error. Their ability to generate significant power while maintaining a compact size makes them ideal for heavy equipment, enabling manufacturers to streamline operations and enhance output.

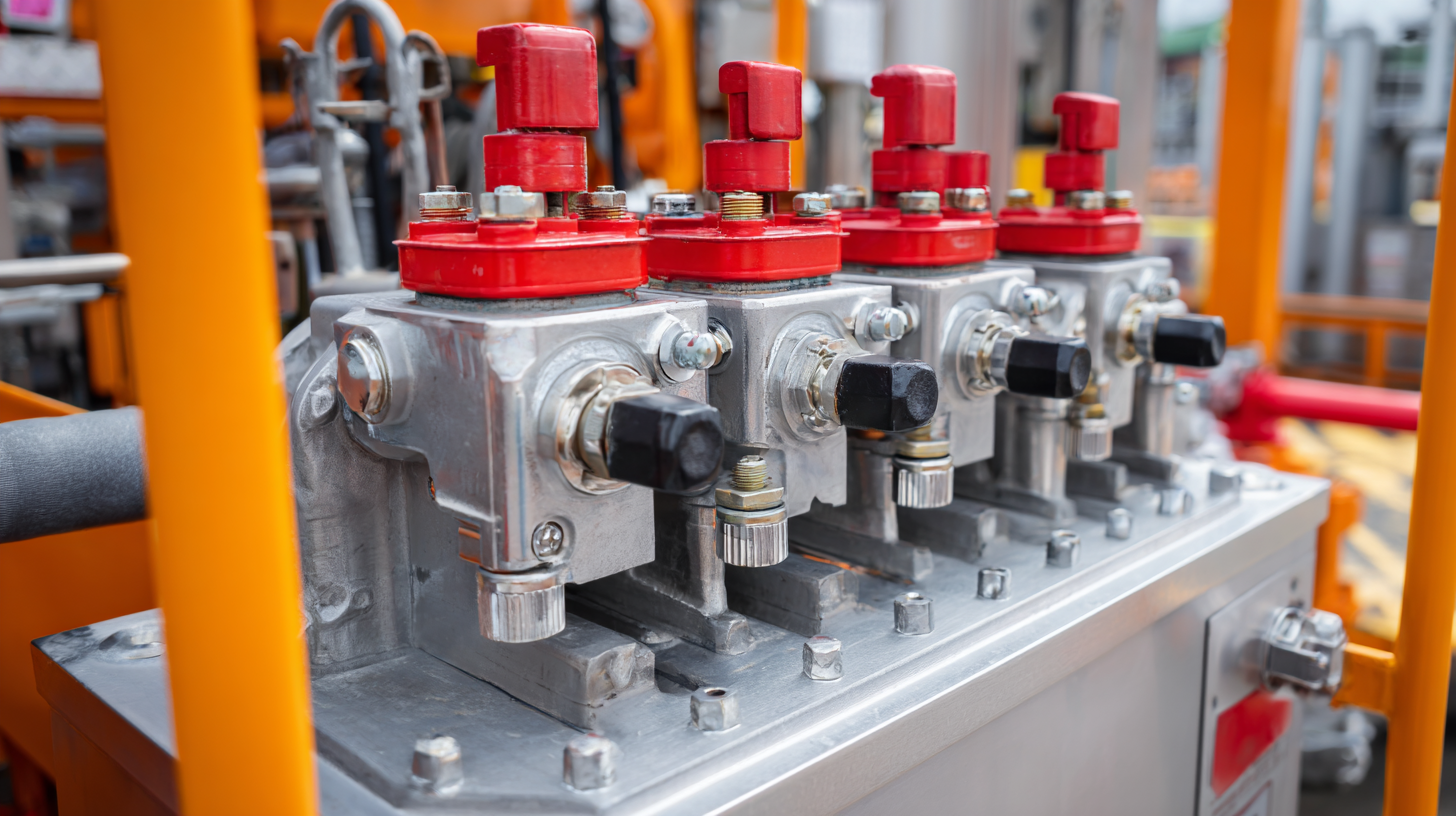

Additionally, the construction industry has seen a transformative impact from hydraulic technology. Hydraulic gas pumps provide the necessary force to operate a wide range of tools and machinery, from excavators to concrete pumps. This efficiency not only accelerates project timelines but also enhances safety by minimizing manual labor. As this technology continues to evolve, industries are poised to further harness its capabilities, driving innovations and improving operational workflows across various sectors.

Best Practices for Implementing Hydraulic Gas Pumps Effectively

Implementing hydraulic gas pumps effectively requires a strategic approach to maximize their efficiency and reliability in industrial applications. According to a report by the International Energy Agency, hydraulic systems can improve energy efficiency by up to 25% when compared to traditional pneumatic systems. This substantial reduction in energy consumption not only lowers operational costs but also minimizes the environmental impact, making hydraulic gas pumps an attractive option for modern industries.

To optimize the implementation, best practices include regular maintenance schedules and proper system design. Research from the Fluid Power Society indicates that nearly 80% of hydraulic system failures are linked to inadequate maintenance. Therefore, prioritizing routine inspections and adhering to manufacturer guidelines can significantly enhance the reliability and lifespan of hydraulic gas pumps. Additionally, ensuring the correct sizing and selection of pumps for specific applications can lead to improved performance and energy efficiency. Adapting these best practices not only streamlines operations but also positions businesses to leverage the full potential of this innovative technology.

Comparative Analysis: Hydraulic Gas Pumps vs. Traditional Systems

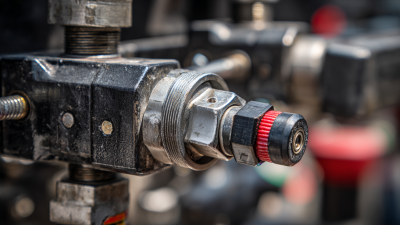

Hydraulic gas pumps have emerged as a transformative force in various industrial applications, especially when compared to traditional pump systems. Traditional pumps often rely on mechanical components that can lead to wear and tear, resulting in decreased efficiency and increased maintenance costs. In contrast, hydraulic gas pumps operate through fluid power, which allows for higher efficiency and durability. This fluid-driven approach minimizes friction and mechanical failures, leading to longer operational life and lower downtime.

Moreover, the adaptability of hydraulic gas pumps in different environments showcases their superiority. Traditional systems may struggle with varying fluid viscosities and temperatures, whereas hydraulic gas pumps are designed to handle diverse operational conditions seamlessly. This versatility not only enhances productivity but also reduces the need for complex systems to manage different applications. As industries strive for greater efficiency and cost-effectiveness, the comparative advantages of hydraulic gas pumps, such as enhanced performance and reliability, position them as a key player in the evolution of industrial pumping solutions.

Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications

| Feature | Hydraulic Gas Pumps | Traditional Systems |

|---|---|---|

| Power Efficiency | 85-90% | 70-75% |

| Maintenance Frequency | Low (Annual) | High (Quarterly) |

| Operational Noise Level | Low | Moderate |

| Weight (per unit) | 150 kg | 250 kg |

| Initial Cost | $5,000 | $3,000 |

| Lifespan | 10-15 years | 5-10 years |

Future Trends in Hydraulic Gas Pump Technology and Efficiency

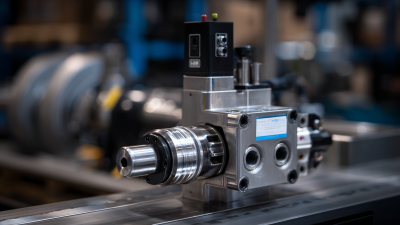

The future of hydraulic gas pump technology is poised for significant advancements that promise enhanced efficiency and sustainability across various industrial applications. Innovations in materials, such as lightweight composites and advanced metals, are being developed to reduce wear and tear, increase durability, and optimize performance. Furthermore, the integration of smart technologies—including IoT sensors and predictive analytics—will enable real-time monitoring and maintenance, ensuring that these pumps operate at peak efficiency while minimizing downtime.

Additionally, the shift towards eco-friendly practices is influencing the design and operation of hydraulic gas pumps. Manufacturers are focusing on energy-efficient systems that reduce power consumption and emissions, aligning with global sustainability goals. Enhanced designs that include variable speed drives and energy recovery systems are emerging, allowing hydraulic gas pumps to adapt their operations based on demand. This evolution not only contributes to operational cost savings but also supports industries in achieving their environmental goals, marking a transformative era in hydraulic technology.

Related Posts

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

Maximizing Efficiency with Well Pressure Pumps for Sustainable Water Solutions