Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

The hydraulic pump plays a crucial role in modern industrial applications, serving as the heartbeat of hydraulic systems that power a wide range of machinery and processes. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 15.68 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.3% from 2020.

The hydraulic pump plays a crucial role in modern industrial applications, serving as the heartbeat of hydraulic systems that power a wide range of machinery and processes. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 15.68 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.3% from 2020.

This growth is fueled by the increasing demand for efficient and reliable fluid power solutions across various industries, including construction, manufacturing, and automotive. As industries strive for greater energy efficiency and automation, the importance of hydraulic pumps cannot be overstated. Their ability to provide high power-to-weight ratios and precise control makes them indispensable for tasks ranging from lifting heavy loads to operating complex machinery.

Understanding the significance of hydraulic pumps is essential for optimizing system performance and ensuring the sustainability of industrial operations.

The Role of Hydraulic Pumps in Enhancing Operational Efficiency Across Industries

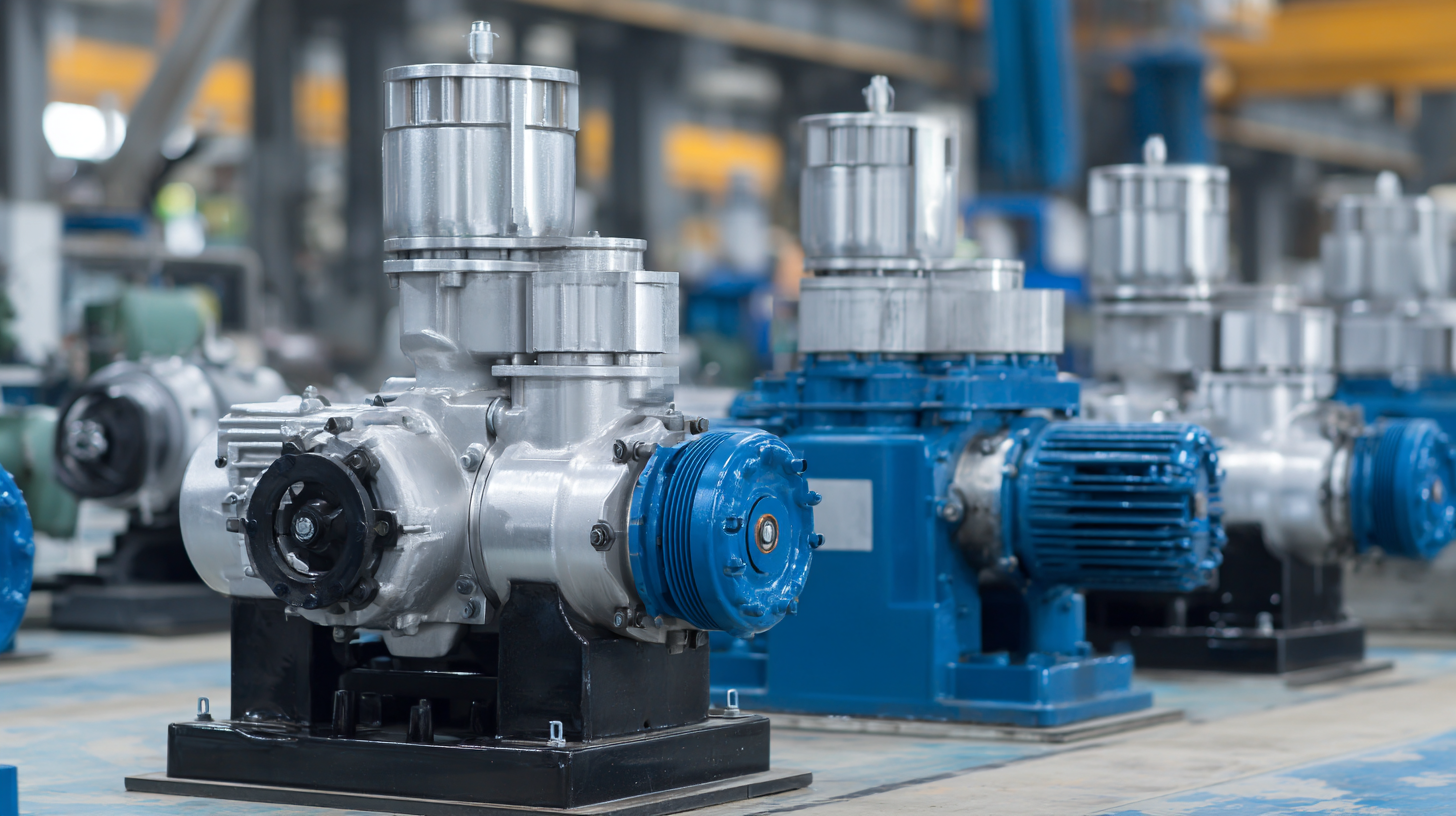

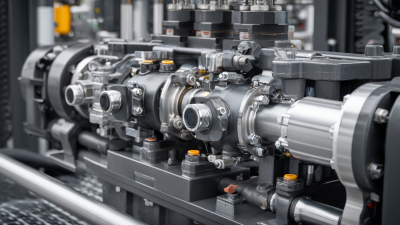

Hydraulic pumps play a crucial role in enhancing operational efficiency across various industries, serving as the heart of hydraulic systems that govern machinery and processes. According to a report by TechSci Research, the global hydraulic pumps market is expected to reach USD 22.63 billion by 2025, growing at a CAGR of 5.6%. This growth highlights the increasing reliance on hydraulic systems, which are instrumental in applications such as manufacturing, construction, and agriculture. By providing high power density and reliable performance, hydraulic pumps contribute significantly to reducing operational costs and increasing productivity.

In the manufacturing sector, for instance, hydraulic pumps are essential for powering machinery and equipment, enabling precise control and enhanced speeds. A study published by MarketsandMarkets estimates that hydraulic machinery accounts for more than 30% of total machinery usage in this industry. By utilizing hydraulic pumps, manufacturers can achieve better energy efficiency and improved process automation, resulting in reduced downtime and waste. Additionally, in the construction and mining sectors, hydraulic pumps facilitate the movement of heavy loads and aid in efficient material handling, further solidifying their importance in driving operational success.

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

| Application Industry | Hydraulic Pump Type | Efficiency (%) | Common Uses | Advantages |

|---|---|---|---|---|

| Construction | Gear Pump | 90 | Excavators, Loaders | Durability, Compact Size |

| Manufacturing | Piston Pump | 95 | CNC Machines, Presses | High Pressure, Versatility |

| Agriculture | Vane Pump | 85 | Sprayers, Tractors | Smooth Operation, Low Noise |

| Mining | Axial Piston Pump | 92 | Dredging, Drilling | High Efficiency, Compact Design |

| Automotive | External Gear Pump | 88 | Power Steering, Braking Systems | Reliable, Efficient |

Key Types of Hydraulic Pumps and Their Applications in Industrial Settings

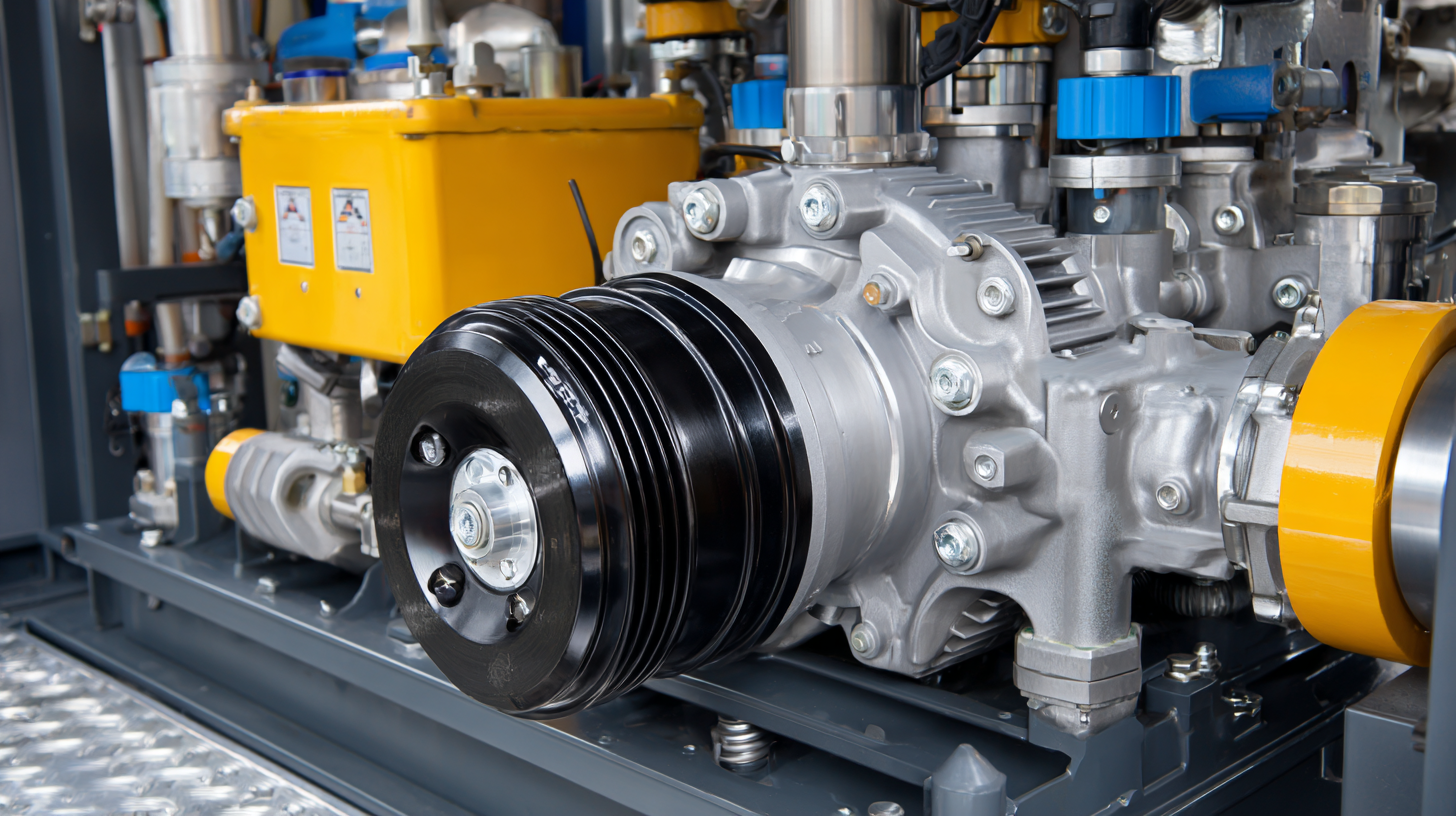

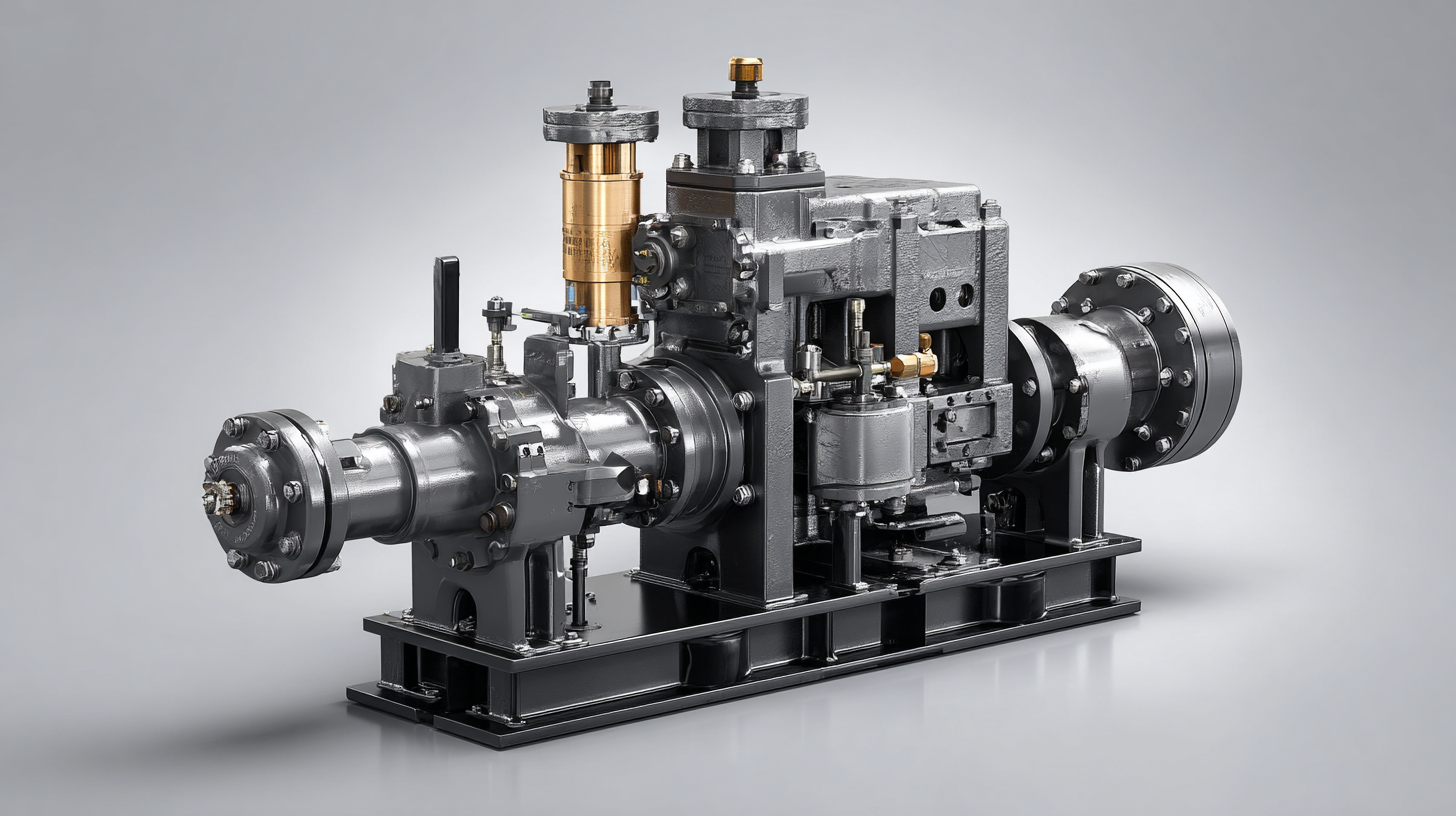

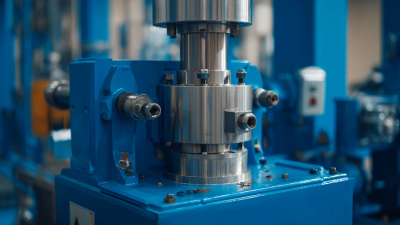

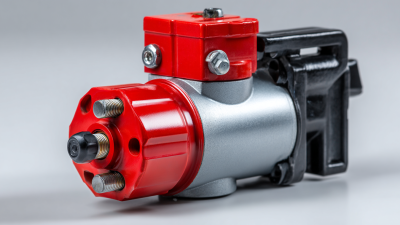

Hydraulic pumps play a pivotal role in modern industrial applications, serving as the heart of hydraulic systems that drive machinery across various sectors. The principal types of hydraulic pumps include gear pumps, vane pumps, and piston pumps, each with distinct advantages tailored to specific uses. Gear pumps, renowned for their simplicity and efficiency, are commonly utilized in automotive and manufacturing industries, where reliability is paramount. According to a report by MarketsandMarkets, the global hydraulic pump market is projected to reach USD 22.08 billion by 2026, underscoring the growing demand for these components in industrial operations.

Vane pumps, on the other hand, are favored for their versatility and smooth operation, finding applications in mobile machinery and agricultural equipment. Their ability to maintain constant flow rates makes them ideal for precision tasks. Piston pumps, best known for their high pressure and efficiency, are extensively used in heavy-duty applications such as construction and mining. As noted in a recent study published by Research and Markets, advancements in hydraulic pump technology are expected to elevate performance standards, enabling better energy efficiency and enhanced operational capabilities across diverse industrial settings.

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

This chart illustrates the distribution of different types of hydraulic pumps commonly used in industrial applications, highlighting the importance of each type in various operational settings.

Analyzing Market Trends: The Growing Demand for Hydraulic Pumps in Global Industries

The growing demand for hydraulic pumps is prominently illustrated by recent market analyses highlighting significant trends in various industrial sectors. The global hydraulic pump market is projected to increase from approximately $1.0759 billion in 2025 to around $1.4661 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.8%. This robust growth can be attributed to key market drivers such as industrial automation, advancements in fluid control technologies, and the rising need for efficient power transmission systems across different industries.

Furthermore, the expansion of the hydraulic components market is evident in the anticipated growth of high-pressure piston pumps, driven by their critical applications in sectors like construction, manufacturing, and mining. The market for these devices is expected to grow steadily, with a projected CAGR of 3.4% from 2025 to 2033. Additionally, the rise of smart and intelligent pump technologies, with an estimated market size of $1.72 billion by 2025 and a growing interest among manufacturers and users, underscores the shift towards more efficient and innovative solutions within hydrodynamic systems. The continuous investment in hydraulic infrastructure and technology advancements is set to shape the future landscape of the hydraulic pump market.

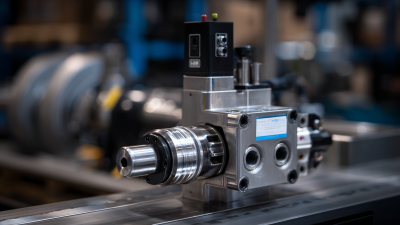

Factors Influencing the Selection of Hydraulic Pumps for Industrial Applications

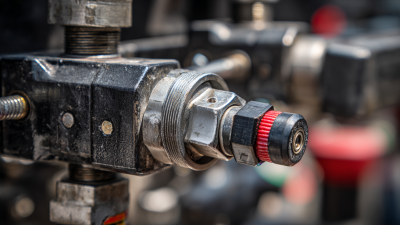

Hydraulic pumps play a critical role in various industrial applications, and their selection is influenced by several key factors. According to recent market analysis, the global hydraulic pump market is projected to grow at a CAGR of 4.0%, reflecting an increasing demand across multiple sectors. The choice of hydraulic pump type—whether it be gear, vane, or piston pumps—depends heavily on the specific application requirements, such as flow rate and pressure range. For instance, multi-screw pumps are growing in popularity within modern industries because of their efficiency and reliability, making them suitable for various operational environments.

Hydraulic pumps play a critical role in various industrial applications, and their selection is influenced by several key factors. According to recent market analysis, the global hydraulic pump market is projected to grow at a CAGR of 4.0%, reflecting an increasing demand across multiple sectors. The choice of hydraulic pump type—whether it be gear, vane, or piston pumps—depends heavily on the specific application requirements, such as flow rate and pressure range. For instance, multi-screw pumps are growing in popularity within modern industries because of their efficiency and reliability, making them suitable for various operational environments.

Additionally, the type of fluid being pumped, operating pressure, and the intended application purpose are pivotal considerations in the selection process. The European industrial lubricants market, valued at USD 21.07 billion in 2023 and expected to reach USD 27.94 billion in the following years, underlines the importance of choosing the right hydraulic pump to ensure compatibility with lubricants and operational efficiency. Companies are also urged to invest in training and certification, capitalizing on the opportunities presented by advancements in pump technologies, as this can significantly impact not only the selection process but overall operational success in industrial settings.

Evaluating the Environmental Impact and Energy Efficiency of Modern Hydraulic Pumps

Hydraulic pumps play a crucial role in various industrial applications, but their

environmental impact and

energy efficiency have become increasingly important concerns.

Modern hydraulic pumps are engineered to minimize energy consumption while ensuring optimal performance, which is vital in a world that is striving for sustainability.

By incorporating advanced materials and innovative designs, manufacturers can significantly reduce the energy required for hydraulic systems to operate effectively, leading to both economic and

environmental benefits.

Furthermore, the environmental implications of hydraulic pumps extend beyond just energy efficiency.

The use of biodegradable hydraulic fluids and the development of

closed-loop systems can greatly diminish the risk of spills and leaks, thereby protecting ecosystems.

Manufacturers are also focusing on reducing noise pollution and enhancing the recyclability of pump components at the end of their lifecycle.

As industries work to comply with stricter environmental regulations, the focus on

energy-efficient and eco-friendly hydraulic pumps is not just advantageous

but essential for sustainable growth in modern industrial applications.

Related Posts

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications

-

5 Essential Tips for Choosing the Right Surface Jet Pump for Your Needs