7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

In the increasingly competitive landscape of industrial applications, the importance of efficiency cannot be overstated. The ultra jet pump has emerged as a groundbreaking solution, designed to optimize performance in various sectors, from oil and gas to water treatment. According to a recent report by the International Energy Agency, systems incorporating advanced pumping technologies can achieve efficiency gains of up to 30%, significantly reducing operational costs and energy consumption. As industries strive to meet growing demands while minimizing environmental impact, understanding how to maximize the capabilities of ultra jet pumps becomes crucial. This blog explores seven best practices to enhance operational efficiency utilizing ultra jet pumps, ensuring not just improved productivity but also sustainability in your processes.

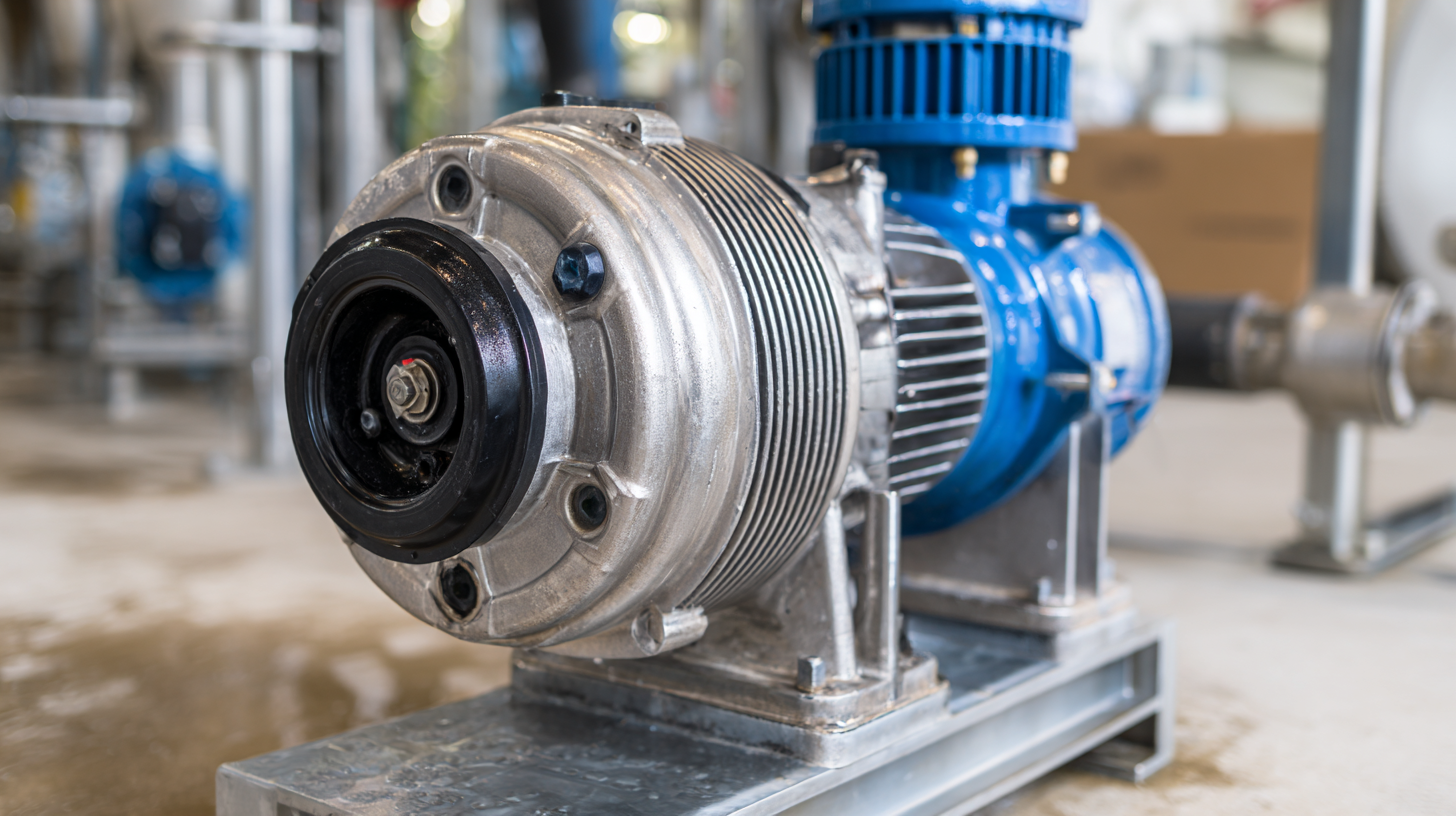

Understanding the Basics of Ultra Jet Pumps for Improved Efficiency

Ultra jet pumps are innovative devices designed to harness the power of fluid dynamics for various applications. Understanding their basic principles is crucial for anyone looking to improve efficiency in their operations. At their core, ultra jet pumps use high-velocity jets of liquid to create a low-pressure zone, drawing in additional fluids through venturi effects. This principle not only aids in fluid mixing but also enhances the overall performance of pumping systems.

To maximize efficiency with ultra jet pumps, it’s essential to consider factors such as fluid viscosity, temperature, and pumping requirements. Optimizing the jet nozzle design and ensuring proper alignment can significantly reduce energy consumption while increasing flow rates. Furthermore, regular maintenance and monitoring of the pumping system can help identify issues before they lead to performance setbacks. By focusing on these fundamentals, users can unlock the full potential of ultra jet pumps, leading to better productivity and cost savings in their operations.

Optimizing Pump Settings for Maximum Performance and Energy Savings

When it comes to optimizing pump settings for ultra jet pumps, fine-tuning operational parameters is essential for maximizing both performance and energy savings. The first step is to adjust the pump's flow rate to match the specific requirements of your system. By setting the flow rate to the optimal level, you can reduce energy consumption while ensuring that the pump operates efficiently. Regularly monitoring and adjusting the pressure settings can also lead to substantial energy savings, as running the pump at lower pressures when possible minimizes unnecessary power draw.

Furthermore, utilizing advanced control systems can enhance the overall efficiency of ultra jet pumps. These systems allow for real-time adjustments based on varying demand, ensuring that the pump operates only as hard as needed. Implementing a variable frequency drive (VFD) can also be a game-changer, allowing for precise control over pump speed and further reducing energy waste. Ultimately, keeping all components well-maintained and performing regular system audits will not only optimize performance but also extend the lifespan of the pump, leading to sustainable energy savings in the long run.

Maximizing Efficiency with Ultra Jet Pumps

Maintaining Your Ultra Jet Pump: Essential Tips for Longevity and Efficiency

Maintaining your ultra jet pump is essential for ensuring longevity and maximizing efficiency in its operation. One of the crucial tips is to regularly check and clean the pump's filter. Debris can accumulate over time, leading to reduced performance. By keeping the filter clean, you can help your pump run smoothly and avoid unnecessary wear and tear.

Another important practice is to monitor the pump’s pressure levels. High or fluctuating pressure can indicate underlying issues that, if addressed early, can prolong the pump’s lifespan. Regular monitoring allows you to make necessary adjustments and identify problems before they escalate.

Additionally, consider scheduling routine professional maintenance. A qualified technician can perform thorough inspections and maintenance tasks that go beyond basic upkeep, significantly enhancing the pump's efficiency. Investing time and resources into these maintenance tips will ensure that your ultra jet pump operates at peak performance for years to come.

Integrating Automation Technology to Enhance Pump Operation

In today's competitive industrial landscape, integrating automation technology is essential to enhance the operation of ultra jet pumps. Automated systems can significantly increase the efficiency of pump management, leading to reduced operational costs. According to a report by the International Pumps Manufacturers Association, automation can boost pump efficiency by up to 25%, primarily by optimizing speed and load conditions. This increased efficiency not only accelerates production rates but also leads to better energy consumption, which is critical in minimizing overhead costs.

Moreover, the application of Internet of Things (IoT) technology in pump systems allows for real-time monitoring and predictive maintenance. A study from the American Society of Mechanical Engineers indicates that predictive maintenance can reduce equipment downtime by 30% and extend the lifespan of pumping systems by as much as 40%. With automated alerts and data analytics, operators can preemptively address potential issues before they escalate, ensuring seamless operations and enhancing overall system reliability. Embracing these technological advancements not only improves performance but also aligns with sustainability goals by reducing energy footprints and resource waste.

Analyzing System Design: Best Practices for Ultra Jet Pump Efficiency

When it comes to maximizing the efficiency of ultra jet pumps, a thorough analysis of system design is crucial. Research from the Hydraulic Institute indicates that optimizing pump design can lead to a 15-25% increase in overall system efficiency. This improvement is primarily achieved through the careful selection of pump size, layout, and materials. For instance, using high-efficiency impellers and reducing turbulence in piping can significantly enhance the hydraulic performance of the system.

Moreover, the integration of smart monitoring systems allows for real-time assessment of pump performance, which is essential for identifying inefficiencies promptly. According to a report by the American Society of Mechanical Engineers (ASME), predictive maintenance enabled by such technologies can reduce downtime by up to 30%. This proactive approach not only prolongs the lifespan of the pumps but also optimizes energy consumption, ultimately leading to significant cost savings for operations reliant on ultra jet pumps. Incorporating these best practices into system design not only enhances efficiency but also aligns with industry standards for sustainable operations.

Related Posts

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

Mastering Sucker Rod Pump Efficiency through Advanced Techniques and Industry Insights

-

5 Essential Tips to Maximize Efficiency with Ultra Jet Pumps in Your Industry

-

Streamlining Efficiency: Innovative Solutions for Gas Well Pump Operations in Oil and Gas Industry

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data