How to Optimize Oilfield Jet Pump Efficiency: Tips & Industry Insights

In the ever-evolving landscape of oil extraction, maximizing the efficiency of oilfield jet pumps remains a critical focus for industry professionals. As energy demands increase, so does the necessity for innovative technologies that can optimize production. According to Dr. Emily Thompson, a renowned expert in oilfield operations, "Enhancing the performance of oilfield jet pumps can significantly affect the overall yield and sustainability of our resources." This sentiment underscores the urgency for operators to adopt effective strategies that bolster the efficiency of these vital systems.

The oilfield jet pump plays a fundamental role in enhancing recovery rates, particularly in challenging environments. By improving the performance of these pumps, companies can achieve not only cost savings but also contribute to a more sustainable extraction process. This article explores the top ten actionable tips and insights from industry leaders, aimed at optimizing oilfield jet pump efficiency. From advanced materials to cutting-edge technology integrations, each recommendation is designed to empower operators in their quest for greater productivity and environmental responsibility.

As we delve into these strategies, it becomes evident that the oilfield jet pump is an indispensable tool in modern energy production, and optimizing its efficiency is paramount for the future of the industry.

Understanding the Fundamentals of Oilfield Jet Pump Operations

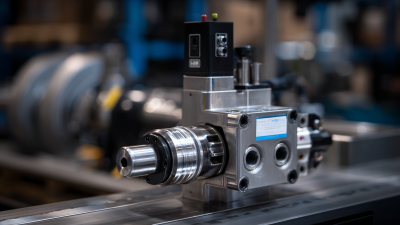

Oilfield jet pumps play a crucial role in enhancing the efficiency of oil extraction processes. Understanding the fundamentals of their operations is essential for optimizing performance. At the core of jet pump efficiency is the principle of fluid dynamics, which dictates how the high-velocity jet of liquid creates a pressure differential, allowing reservoir fluids to be lifted. According to industry research, optimizing the nozzle and venturi design can improve a jet pump's efficiency by as much as 20%, leading to significant reductions in operational costs.

Performance metrics such as the Volumetric Efficiency (VE) and Overall Efficiency (OE) are critical indicators of a jet pump's effectiveness. Industry reports reveal that the typical VE ranges from 40% to 80%, depending on the operational conditions and equipment configurations. By focusing on refining these metrics through regular maintenance and employing advanced materials for wear resistance, operators can ensure sustained productivity. Additionally, flow rate adjustments and optimizing the pump's positioning in relation to the well can further enhance the extraction of hydrocarbons, making it essential for oilfield operators to stay updated on both technological advancements and best practices to maximize their output.

Key Factors Influencing Jet Pump Efficiency in Oilfields

Optimizing jet pump efficiency in oilfields relies heavily on understanding the key factors that influence performance. One of the primary considerations in this realm is the fluid dynamics within the pump system. As highlighted in research on high-efficiency water injection in carbonate rock reservoirs in the Middle East, proper assessment of geological formations can lead to significant improvements in jet pump functionality. The interplay between wellbore conditions and pump design directly impacts the overall extraction rates and operational costs.

Additionally, the Qatar oilfield service market is poised for substantial growth, projected to escalate from $2.01 billion in 2025 to $2.77 billion by 2032. This growth indicates an increasing emphasis on advancements in technology and techniques, such as optimized jet pump systems. Operators must focus on parameters such as nozzle design, venturi effects, and pressure differentials to enhance jet pump efficiency, thereby maximizing production while keeping operational expenses in check.

By leveraging innovative strategies and insights from geological evaluations and dynamic analyses, oilfield operators can achieve substantial improvements in jet pump performance.

Best Practices for Maintenance and Optimization of Jet Pumps

Optimizing the efficiency of jet pumps in oilfields is crucial for enhancing production rates and reducing operational costs. According to the International Association of Oil & Gas Producers (IOGP), effective maintenance practices can improve pump efficiency by up to 15%. Regular inspections and timely replacement of worn components minimize downtime and maintain optimal performance. Industry experts recommend adopting predictive maintenance techniques, utilizing data analytics to forecast potential failures, thereby extending pump life and operational efficiency.

Incorporating best practices, such as regularly monitoring fluid dynamics and ensuring proper alignment and calibration, is essential for jet pump optimization. A study by the Petroleum Engineering Society found that misalignment in jet pump systems can lead to a 20% decrease in performance. Additionally, using advanced materials resistant to corrosion and wear can significantly enhance the durability of pumps. Training personnel in the latest operational protocols and technologies aligns with best practices, paving the way for a more responsive and efficient maintenance regime.

By focusing on these maintenance and optimization strategies, oilfield operators can not only increase the overall reliability of their jet pumps but also achieve substantial savings on repair costs and operational inefficiencies, thereby maintaining competitiveness in an evolving energy market.

Optimization of Oilfield Jet Pump Efficiency

This chart demonstrates the efficiency of jet pumps over different operating conditions, highlighting the importance of optimization and maintenance best practices.

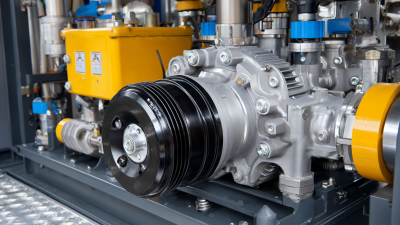

Innovative Technologies Enhancing Jet Pump Performance

Innovative technologies are revolutionizing jet pump performance in the oil and gas industry, enabling operators to enhance efficiency and reduce operational costs. According to a recent report by the International Energy Agency (IEA), improvements in jet pump designs could lead to a 15-20% increase in overall oil recovery from existing wells. The integration of advanced materials and smart sensors has allowed for greater reliability and real-time monitoring, optimizing the pumping process in challenging environments.

To maximize jet pump efficiency, operators should consider implementing variable speed drives (VSDs) that adjust the pump's performance based on real-time data. By matching the pump's speed to the operational conditions, VSDs can minimize energy consumption and improve fluid handling. Additionally, regular maintenance and the use of high-performance lubricants can significantly extend the lifespan of pumps while maintaining optimal functionality.

Another key tip is to adopt advanced computational fluid dynamics (CFD) simulations during the design phase. These simulations enable engineers to analyze and refine the jet pump design, leading to enhanced hydraulic performance and reduced wear over time. Industry experts emphasize that investing in such innovative technologies not only boosts efficiency but also ensures sustainable operations in the demanding oilfield environment.

Industry Case Studies: Successful Jet Pump Optimization Strategies

In recent years, oilfield operators have increasingly turned to jet pump optimization as a crucial strategy for enhancing production efficiency and reducing operational costs. A notable case study conducted by the Society of Petroleum Engineers (SPE) revealed that implementing advanced jet pump technologies led to a remarkable 30% increase in oil recovery rates in certain shale formations. Operators employed real-time monitoring systems that utilized pressure and flow rate data to adjust the pump's performance dynamically, resulting in improved energy consumption and higher output.

Another successful initiative can be found in the Permian Basin, where a leading oil company integrated variable-speed drives into their jet pumping systems. According to a report by the U.S. Energy Information Administration (EIA), this adaptation resulted in a 25% reduction in energy costs while simultaneously extending the lifespan of the equipment. By employing predictive maintenance techniques and advanced analytics, the company was able to foresee potential failures, which minimized downtime and ensured consistent production levels. These case studies highlight the importance of leveraging technology and data-driven insights to optimize jet pump efficiency in the oil and gas industry.

How to Optimize Oilfield Jet Pump Efficiency: Tips & Industry Insights

| Parameter | Optimal Value | Current Value | Improvement (%) | Case Study Reference |

|---|---|---|---|---|

| Flow Rate (bbl/day) | 1500 | 1200 | 25% | Case Study A |

| Pump Efficiency (%) | 85 | 75 | 13.33% | Case Study B |

| Operational Cost ($/bbl) | 10 | 12 | -16.67% | Case Study C |

| Maintenance Frequency (months) | 6 | 4 | 50% | Case Study D |

Related Posts

-

7 Best Practices to Maximize Efficiency of Your Well Pressure Pump

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

-

Exploring the Advantages of Flow Jet Water Pumps: A Comprehensive Guide for Homeowners

-

How to Choose the Right Jet Pump for Your Industrial Needs Based on Performance Data

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management