What is a Surface Jet Pump and How Does It Work?

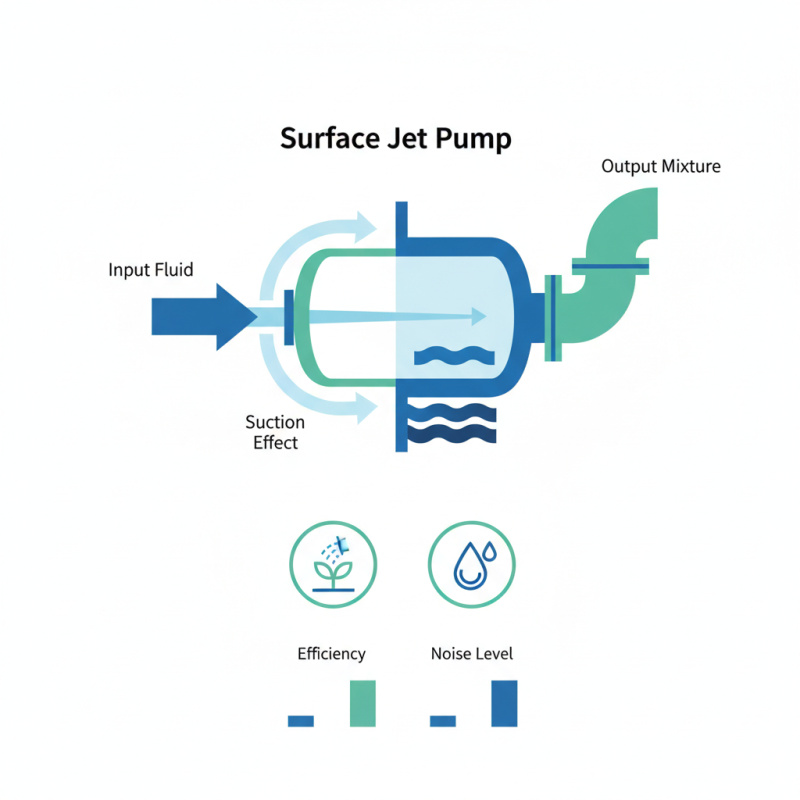

A surface jet pump is a fascinating device used to move fluids efficiently. It operates based on a simple yet effective principle. This pump relies on a jet of fluid to create a suction effect. It commonly finds applications in various industries, including agriculture and water treatment.

Understanding how a surface jet pump works is essential for effective deployment. It functions without any moving parts, which minimizes maintenance needs. The design often includes a nozzle that directs a high-velocity fluid stream. As the fluid passes through the nozzle, it generates a low-pressure area. This pressure difference pulls additional liquid into the system.

Despite its advantages, there are drawbacks. The efficiency of a surface jet pump can be affected by its design and planned usage. Sometimes, noise levels can be an issue. Users may also struggle with specific performance parameters. Reflecting on these aspects can lead to better applications and innovations in fluid transfer technology.

What is a Surface Jet Pump?

A surface jet pump is a versatile device used primarily in water transfer applications. It operates on the principle of hydraulic energy conversion. In simple terms, it uses a high-speed jet of water to create a vacuum that draws fluid from a source. This method is efficient, allowing for the movement of large volumes of liquid with minimal energy consumption.

According to industry reports, surface jet pumps can achieve flow rates exceeding 200 gallons per minute, making them suitable for both agricultural and industrial processes. One notable aspect of these pumps is their ability to handle gases and liquids simultaneously. This feature enhances their effectiveness in applications such as wastewater treatment. However, the limitations of cavitation and pressure drop must be considered. Cavitation can lead to reduced efficiency and potential damage to components over time.

Maintenance of surface jet pumps is critical for longevity and performance. Regular checks and servicing can help mitigate some issues. Despite their advantages, improper installation or operation may lead to decreased efficiency. Users should, therefore, be mindful of ensuring proper alignment and seal integrity to avoid common pitfalls. Optimal performance requires attention to detail and ongoing assessment of system conditions.

Principle of Operation for Surface Jet Pumps

Surface jet pumps operate based on the principle of fluid dynamics. They utilize a high-velocity fluid stream to create a vacuum that draws in additional fluid. This process is fascinating because it allows a small amount of fluid to move a larger volume. The core design includes an inlet and a nozzle, which transform the pressure of the liquid into kinetic energy.

When water flows through the nozzle, it speeds up significantly. As it exits, the drop in pressure creates a siphoning effect. This effect pulls surrounding liquid into the flow, effectively increasing the total output. It’s a clever mechanism, but there are limitations. The performance can drop if the pump is not correctly sized for the application, or if the inlet is clogged. These situations require careful monitoring.

Regular maintenance can alleviate some of these issues. However, sometimes users overlook basic factors. For instance, water temperature and viscosity can affect efficiency. Not every situation is ideal, and sometimes adjustments are necessary. Engineers must remain vigilant to ensure optimal operation and troubleshoot any inconsistencies. Despite the straightforward design, surface jet pumps highlight the complexity of fluid dynamics in everyday applications.

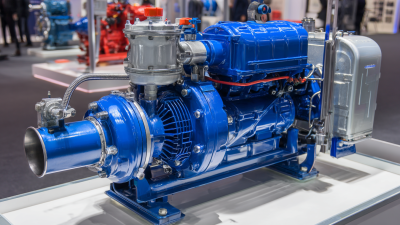

Key Components of a Surface Jet Pump

A surface jet pump is a unique device used to move fluids efficiently. It operates based on a combination of fluid dynamics principles. The design involves several key components that work together to create suction and discharge flows.

The primary element is the nozzle, where pressurized fluid enters. This nozzle creates a high-velocity jet that mixes with a secondary fluid, drawing it into the stream. According to industry reports, well-designed nozzles can improve flow rates by up to 40%. The mixing chamber follows, where the two streams converge. This chamber is crucial as it allows for even distribution and prevents turbulence.

Another integral component is the diffuser. It converts the kinetic energy of the fluid into pressure energy, ensuring the fluid exits the pump at a higher pressure compared to its entry. A study published by the Hydraulic Institute indicates that pumps with optimal diffuser designs can achieve efficiencies greater than 70%. However, not all designs cater to this efficiency, leading to potential energy losses. Lastly, the venturi section plays a significant role in maintaining the necessary pressure differential for proper operation. A poorly designed venturi can drastically reduce effectiveness and lead to maintenance challenges. Understanding these components aids in optimizing pump design and improving performance in various applications.

Performance Comparison of Surface Jet Pumps

Common Applications of Surface Jet Pumps

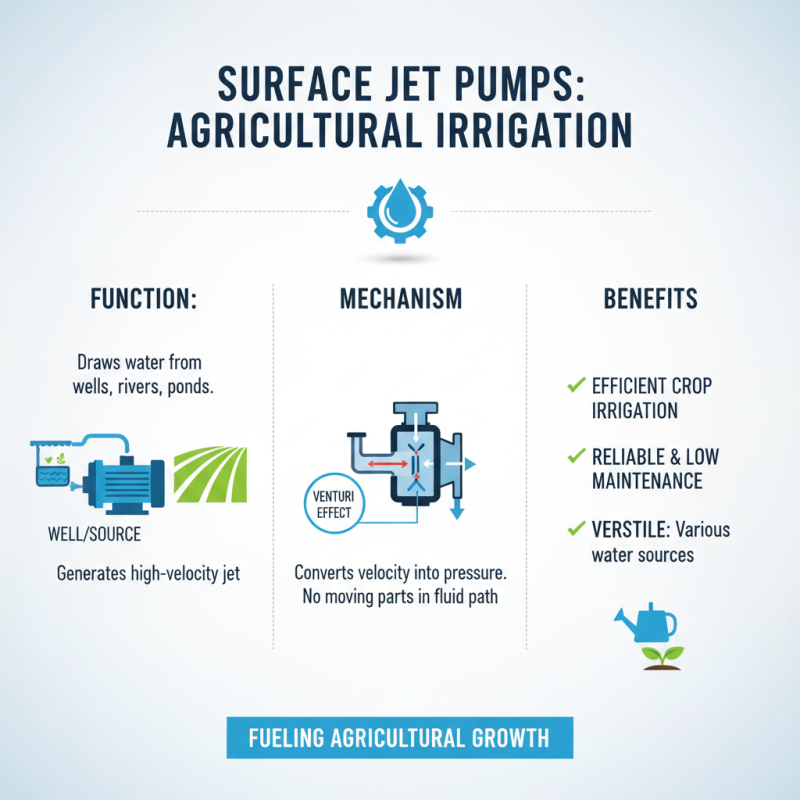

Surface jet pumps are versatile tools widely used in various industries. Their ability to pump fluids effectively makes them valuable in many applications. One common use is in agriculture, where these pumps help to irrigate crops. They can draw water from wells or nearby sources, ensuring crops receive adequate moisture.

Another significant application is in the oil and gas industry. Surface jet pumps assist in enhancing oil recovery. By creating a vacuum, they can lift heavy fluids from underground reservoirs. They are essential during extraction operations, improving efficiency but sometimes not as effective in all conditions.

In the manufacturing sector, these pumps find use in cooling systems. They move liquids to regulate temperatures in machinery. Their reliability is key, but they may require regular maintenance to function optimally. Users often notice that, without proper care, efficiency can decrease over time.

Advantages and Limitations of Surface Jet Pumps

Surface jet pumps offer several advantages that make them popular in various applications. They are relatively simple in design, which makes them easier to maintain. The installation process is straightforward, requiring minimal modifications to existing systems. Additionally, these pumps can efficiently lift water from shallow wells or reservoirs. This capability is particularly beneficial in areas where groundwater is close to the surface.

However, surface jet pumps also have limitations to consider. Their efficiency tends to drop when the water source is too deep, making them unsuitable for deeper applications. They can be noisier than other pumping systems, which may be a concern in residential areas. Furthermore, these pumps may not handle large volumes of water effectively. Users sometimes find that intermittent operation causes wear and tear on the motor. It’s essential to evaluate these factors before selecting a jet pump for your needs.

What is a Surface Jet Pump and How Does It Work? - Advantages and Limitations of Surface Jet Pumps

| Dimension | Details |

|---|---|

| Type | Surface Jet Pump |

| Working Principle | Utilizes a high-velocity jet of water to create suction and draw water from a source |

| Applications | Irrigation, water transfer, and drainage |

| Advantages | Simple design, low maintenance, cost-effective, suitable for shallow wells |

| Limitations | Limited suction depth, less efficient at higher flow rates, sensitive to sand and debris |

| Installation | Typically surface mounted, requires a mixing chamber for optimal performance |

| Maintenance Recommendations | Regular checks for clogs, cleaning of filters and fittings |

Related Posts

-

5 Essential Tips for Choosing the Right Surface Jet Pump for Your Needs

-

2026 How to Choose the Right Surface Jet Pump for Your Needs?

-

Exploring Market Trends: Ultra Jet Pumps at the 138th Canton Fair 2025 in China

-

Exploring Market Trends: Ultra Jet Pump Innovations at the 138th China Import and Export Fair 2025

-

Exploring the Inner Workings and Advantages of Surface Jet Pumps in Modern Water Systems

-

Why Choose Ultra Jet Pumps for Your Water Needs and What Are Their Benefits