Ultimate Tips for Choosing the Right Flow Jet Pump

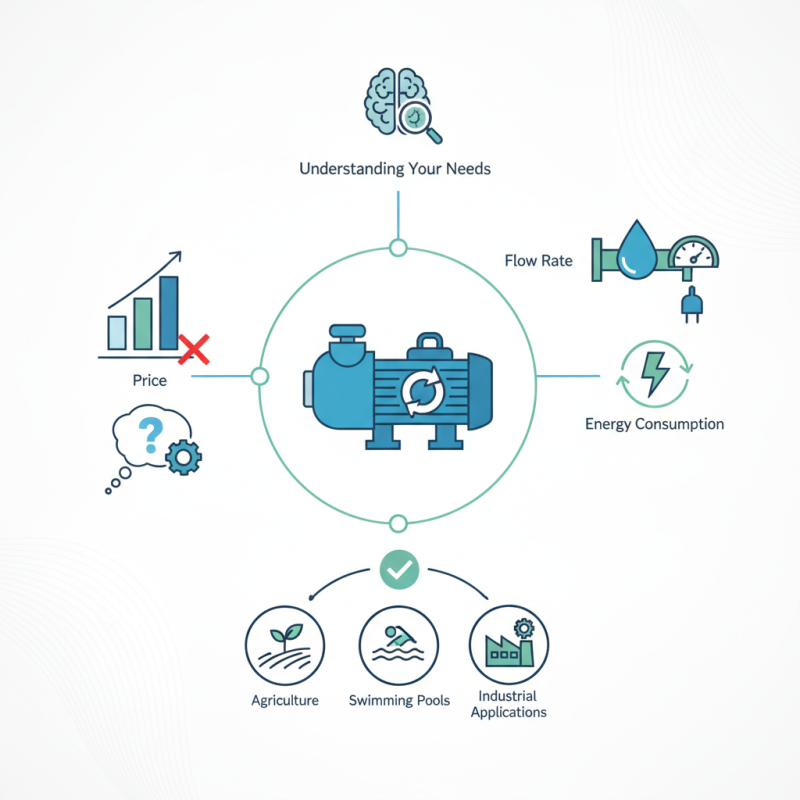

Choosing the right flow jet pump can be a daunting task. Renowned industry expert Dr. Sarah Johnson once said, "Select a pump that meets your specific needs." This simple advice underscores the importance of understanding your requirements before making a choice.

Flow jet pumps are vital for various applications, from agriculture to swimming pools. The right pump can enhance efficiency and reduce costs. However, not all pumps are created equal. Factors like flow rate and energy consumption should be carefully considered.

Many users overlook these details. A common mistake is selecting a pump based solely on price. This approach can lead to performance issues later. Each application has unique demands, and a one-size-fits-all solution rarely works. Taking the time to research can yield significant long-term benefits.

Understanding Flow Jet Pumps: Types and Applications

Flow jet pumps are versatile devices used in various applications. They come in different types, including centrifugal and positive displacement pumps. Each type serves unique purposes suited to specific needs. For instance, centrifugal pumps are effective in transferring large volumes of water quickly, making them ideal for irrigation. They are simple in design but may struggle with viscous fluids.

Positive displacement pumps, on the other hand, excel at handling thicker liquids. These pumps operate differently, creating a vacuum to draw in liquid, then pushing it out. They are often used in industrial settings where precise fluid handling is essential. However, they can be more complex and require more maintenance than centrifugal pumps.

Selecting the right flow jet pump involves weighing these factors carefully. A common mistake is underestimating the fluid characteristics, like viscosity or temperature. This can lead to inefficient operation. It's essential to assess the specific needs of your application. Take time to analyze your requirements thoroughly before making a choice. The wrong pump may complicate operations, leading to increased costs.

Key Factors to Consider When Selecting Flow Jet Pumps

When selecting a flow jet pump, consider several key factors. The pump's size is crucial. Ensure it fits your space and meets your flow requirements. A pump that is too small may not provide enough pressure. Conversely, a larger pump might waste energy. Assess the specific application. Different tasks demand different capabilities. A garden irrigation system will need a different pump than one for a home water supply.

Consider the material of the pump. Corrosion-resistant materials are essential for longevity. If the water source contains impurities, look for suitable materials. This decision can affect your pump’s performance over time. Don’t overlook the energy efficiency rating. A pump with a high efficiency can save on operational costs.

Here are some tips: Always check the installation requirements before purchasing. A complicated setup can lead to increased costs. Monitor the pump regularly for proper performance. Neglecting maintenance can result in decreased efficiency. Be aware of noise levels as some pumps are louder than others. Lastly, account for warranty and support options available. Some products may offer limited service after purchase.

Analyzing Flow Rates and Pressure Requirements for Optimal Performance

When selecting the right flow jet pump, understanding flow rates and pressure requirements is crucial. Flow rates measure how much fluid a pump can deliver. Typically, flow rates are expressed in gallons per minute (GPM) or liters per minute (LPM). A recent industry report indicates that optimal performance often occurs at flow rates between 10 GPM and 30 GPM for residential applications. However, exceeding these rates can lead to cavitation and inefficiency.

Pressure is another vital component. The pressure rating, usually measured in psi, tells you the pump's capability to push fluid against resistance. Many applications require a minimum pressure of 30 psi. Yet, exceeding 60 psi may not be ideal for certain systems. It can increase wear and tear. Additionally, adding features like pressure gauges can help monitor fluctuations. This helps maintain system integrity and performance.

Finding the balance between flow rate and pressure is tricky. Underestimating needs can lead to poor performance. Overestimating can cause unnecessary expenses. It's essential to analyze specific system requirements carefully. Using data from industry reports can guide decisions. Aim for a pump that aligns perfectly with your unique needs. Remember, real-world conditions may vary, so flexibility and adjustment can be key to achieving long-term reliability.

Ultimate Tips for Choosing the Right Flow Jet Pump

This chart illustrates the relationship between flow rates and pressure requirements, helping you identify the optimal performance of various flow jet pumps.

Material Compatibility and Durability in Flow Jet Pump Selection

When selecting a flow jet pump, material compatibility and durability are crucial factors. Many industry reports indicate that nearly 30% of pump failures stem from improper material selection. It’s essential to choose materials that resist corrosion and abrasion. For instance, a stainless steel body can endure harsh environments, while thermoplastics may be suitable for less demanding applications.

Tip: Always analyze the fluid characteristics before making a choice. Is it abrasive? Does it contain corrosive chemicals? This assessment can save you from future headaches.

Durability goes hand in hand with material selection. According to a study by the Fluid Engineering Institute, pumps made from high-quality alloys last 40% longer than those made from standard materials. This longevity translates into fewer replacements and lower operational costs.

Tip: Look for pumps that offer extended warranties. This can be an indicator of the manufacturer's confidence in their durability. Reflect on your specific application needs; cheaper options may seem appealing, but they often don't hold up in the long run. Choosing wisely can prevent costly downtimes and ensure reliable performance.

Maintenance and Long-term Considerations for Flow Jet Pumps

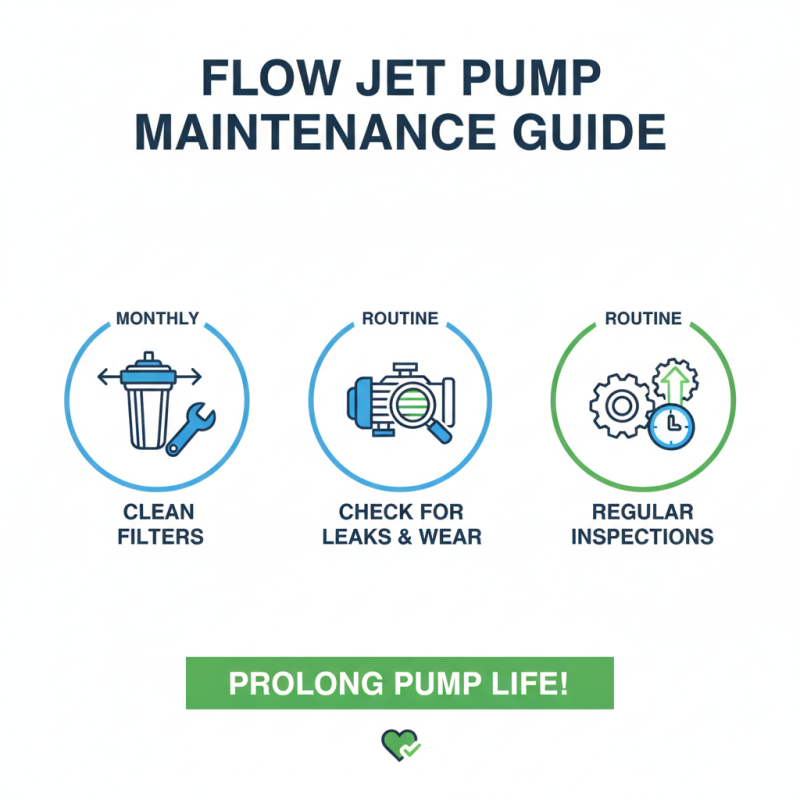

When it comes to flow jet pumps, maintenance is crucial. Regular inspections help identify wear and tear early. Clean filters once a month to ensure smooth operation. Checking the pump for leaks should be routine. These small steps can prolong the pump's life significantly, but many neglect them.

Over time, you may notice a decline in performance. This might indicate the impeller is clogged. Removing debris can seem tedious, yet it's essential. Some users skip this task, leading to more significant issues later. Relying solely on the pump’s automatic features can lead to neglect. Manual checks often reveal problems that need immediate attention.

Additionally, consider the pump’s environment. Is it exposed to harsh weather? Poor conditions can shorten its lifespan. If you aren’t proactive, you may find yourself needing to replace the pump sooner than expected. Reflect on your maintenance practices; there’s always room for improvement.

Related Posts

-

Ultimate Checklist for Selecting the Right Surface Jet Pump for Your Industrial Needs

-

How to Choose the Right Flo Jet Pump for Your Specific Needs

-

5 Essential Tips to Maximize Efficiency with Ultra Jet Pumps in Your Industry

-

Exploring Innovative Alternatives to Flo Jet Pumps for Efficient Fluid Management

-

Exploring Market Trends: Ultra Jet Pumps at the 138th Canton Fair 2025 in China

-

Exploring the Inner Workings and Advantages of Surface Jet Pumps in Modern Water Systems