2025 Top 5 Industrial Pumps: Best Picks for Efficiency and Performance

As the industrial sector continues to evolve, the demand for high-efficiency industrial pumps has never been more critical. According to a report by the International Pump Industry Study, the global market for industrial pumps is projected to reach $80 billion by 2025, driven by rigorous requirements for performance and energy efficiency across various applications. The growing investment in infrastructure and energy sectors dramatically emphasizes the significance of selecting the right pump technology for sustainable operations.

Industry expert Dr. Sarah Thompson, a leading figure in pump technology research, highlighted the importance of innovation in this field by stating, "The future of industrial pumps lies in their ability to combine efficiency with advanced automation features, creating systems that not only reduce operating costs but also enhance overall productivity." This insight underscores the pressing need for companies to adapt to the latest technologies and methodologies in pump design and operation.

In this context, our review of the 2025 Top 5 Industrial Pumps aims to guide businesses in making informed investments in their pumping solutions. By evaluating key aspects such as energy consumption, overall efficiency, and operational reliability, we will present the best options in the market. This will ensure that industries can achieve optimal performance while meeting their sustainability goals in an increasingly competitive landscape.

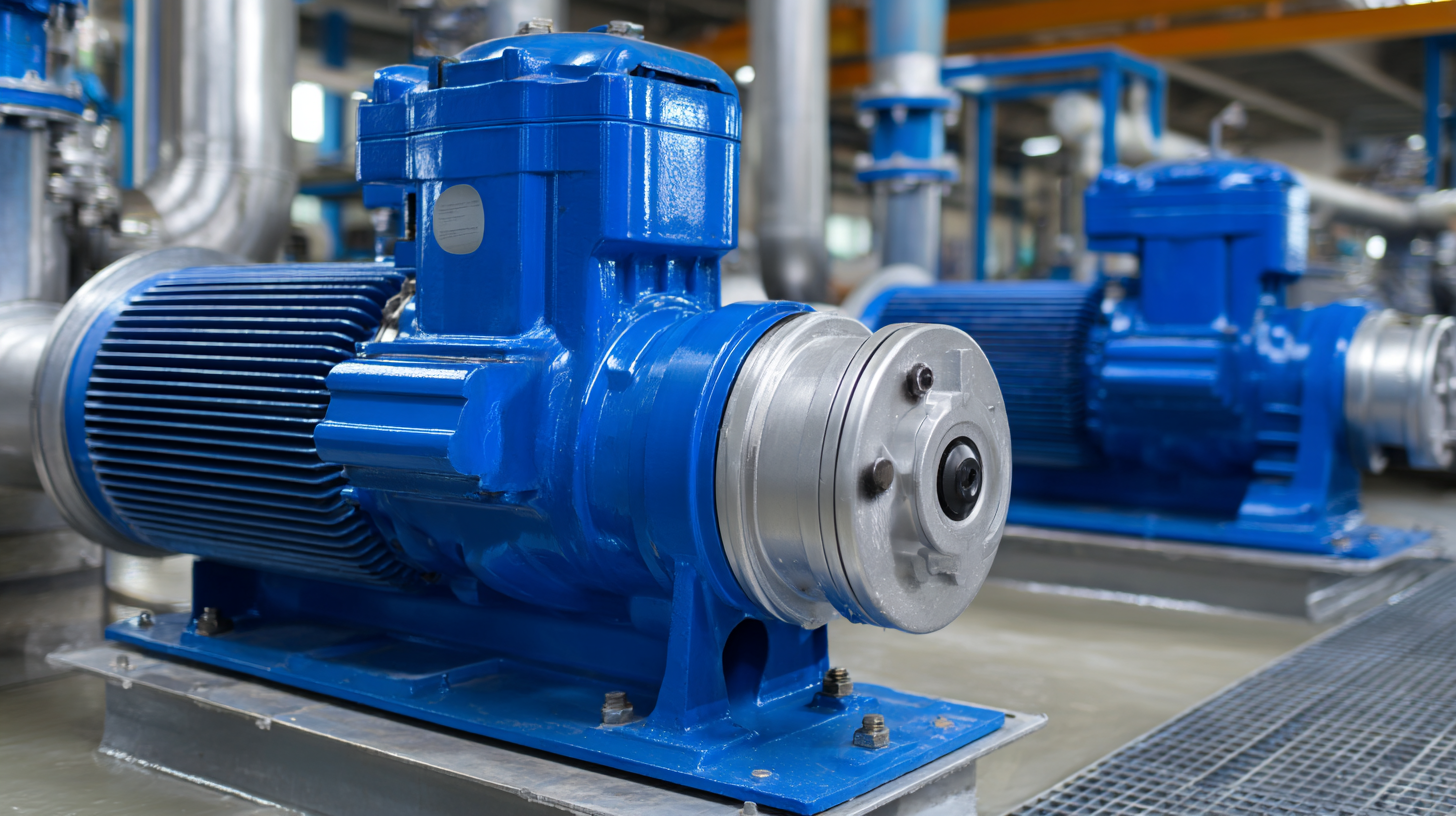

Overview of Industrial Pump Types and Their Applications

The industrial pump market is evolving rapidly, reflecting diverse applications across various sectors. The global market for magnetic pumps is projected to reach $960 million by 2033, growing at a CAGR of approximately 3.6% from an estimated $700 million in 2024. This growth highlights a shift towards more efficient and reliable pump solutions in industries that require precision fluid handling.

In the realm of chemical pumps, the ISO standard market is anticipated to grow from around $8.1 billion in 2024 to $12.6 billion by 2033. This significant increase underscores the rising demand for standardized and efficient pumping solutions in chemical processing industries. Similarly, the North American centrifugal pump market is expected to see steady growth, increasing from $3.94 billion in 2025 to $4.74 billion by 2032, with a CAGR of 2.69%. These trends signify an industry focus on improving operational efficiency and product reliability, fundamental for meeting the demands of modern applications in diverse sectors such as mining, wastewater treatment, and power generation.

Key Factors for Selecting Efficient Industrial Pumps

When selecting efficient industrial pumps, several key factors

must be taken into consideration to ensure optimal performance and longevity. First and foremost,

understanding the specific requirements of the application, including the type of fluid being pumped,

temperature, viscosity, and the total dynamic head, is crucial.

These parameters influence the selection of materials and pump designs that can withstand

operational demands while maintaining efficiency.

When selecting efficient industrial pumps, several key factors

must be taken into consideration to ensure optimal performance and longevity. First and foremost,

understanding the specific requirements of the application, including the type of fluid being pumped,

temperature, viscosity, and the total dynamic head, is crucial.

These parameters influence the selection of materials and pump designs that can withstand

operational demands while maintaining efficiency.

Another important factor is the pump’s energy consumption.

With rising energy costs, choosing pumps designed for energy efficiency can

lead to significant savings over time. Look for features such as variable frequency drives (VFDs)

that allow for better control of pump speed and flow rates, as well as pumps with high efficiency ratings.

Additionally, consider the maintenance ease and reliability of the pump, as lower maintenance needs

contribute to reduced downtime and overall operational costs. By prioritizing these factors, businesses can

ensure they select pumps that not only meet their operational needs but also contribute to a more

sustainable and cost-effective production process.

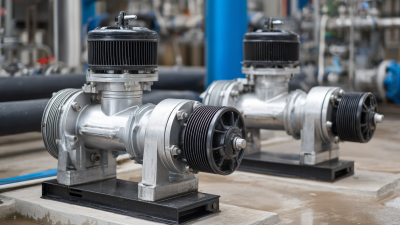

Top 5 Industrial Pumps of 2025: Performance and Efficiency Ratings

In the competitive landscape of industrial pumps, the emphasis on performance and efficiency is more critical than ever. According to a recent report from the Global Pump Industry Analysis (2023), the demand for high-efficiency pumps is projected to grow at a CAGR of 5.4% through 2025. This statistic highlights the necessity for industry players to stay ahead of innovative technologies that enhance energy savings and operational reliability.

When evaluating the top industrial pumps of 2025, key performance metrics such as hydraulic efficiency and energy consumption will play significant roles. The Hydraulic Institute's benchmarks indicate that pumps with energy efficiency ratings above 75% not only reduce operational costs but also minimize environmental impact. For example, the latest centrifugal pump models have shown efficiency improvements of approximately 10% over their predecessors, marking a substantial evolution in pump technology. This upward trend in efficiency ensures that industries can operate within tightened energy regulations while maximizing productivity.

2025 Top 5 Industrial Pumps: Best Picks for Efficiency and Performance

| Pump Model | Type | Efficiency Rating (%) | Max Flow Rate (L/min) | Max Pressure (bar) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | Centrifugal | 85 | 300 | 10 | 120 |

| Model B | Positive Displacement | 90 | 250 | 15 | 160 |

| Model C | Submersible | 88 | 200 | 5 | 70 |

| Model D | Diaphragm | 92 | 150 | 20 | 100 |

| Model E | Gear | 86 | 180 | 12 | 130 |

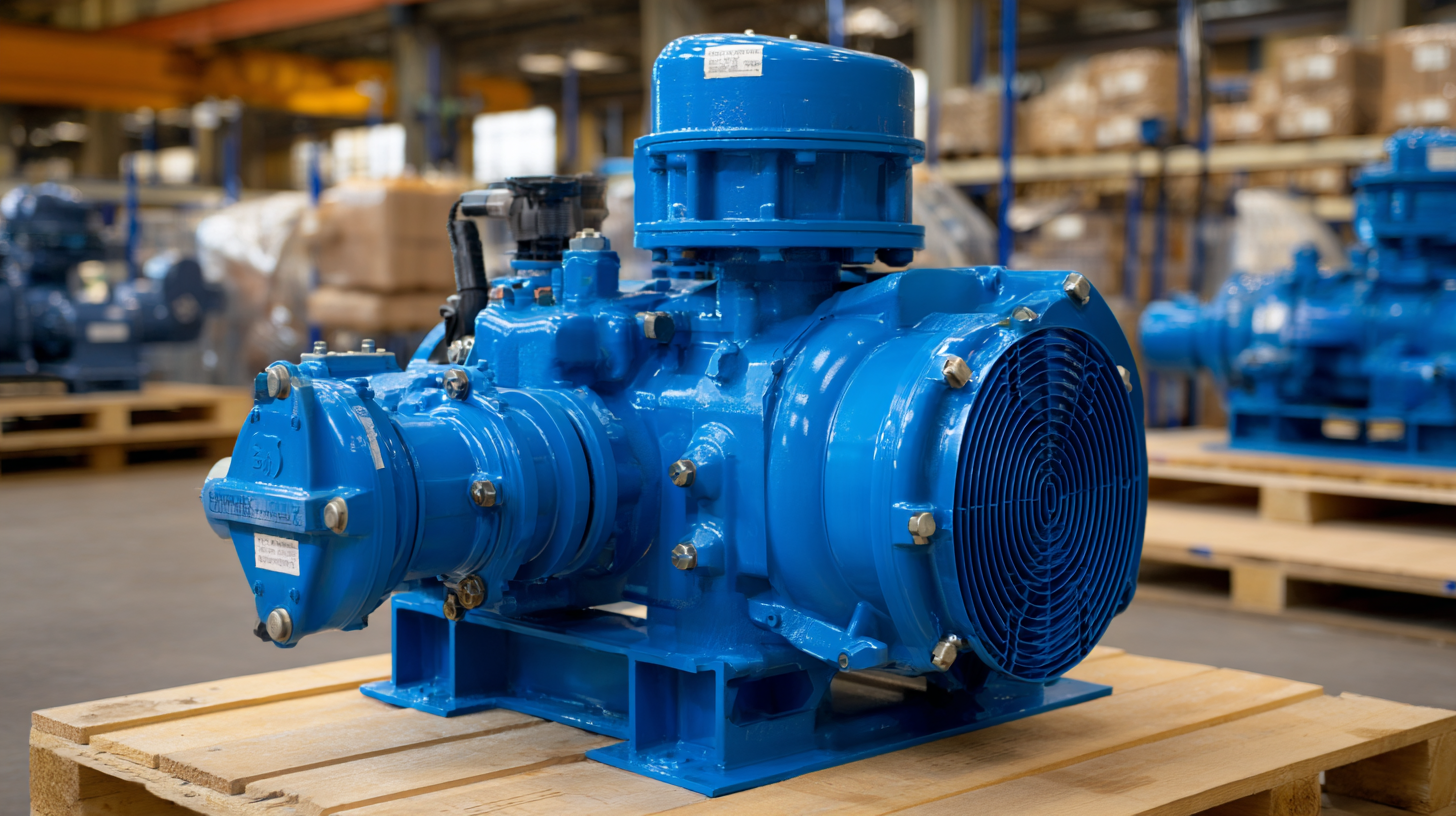

Cutting-Edge Technologies in Industrial Pump Design

The industrial pump market is rapidly evolving with cutting-edge technologies that enhance efficiency and performance. According to a recent report by MarketsandMarkets, the global industrial pump market is expected to reach USD 80 billion by 2025, driven by innovations in design and materials.

One of the most significant advancements is the adoption of smart pump technology. These pumps utilize IoT sensors and data analytics to monitor performance metrics in real-time, significantly reducing energy consumption by up to 30%. This level of monitoring not only optimizes operations but also extends the lifespan of pumps by preventing potential failures.

Moreover, advancements in materials, such as composites and advanced alloys, have enhanced the durability and efficiency of industrial pumps. A report from Grand View Research highlights that the demand for chemically resistant pumps has surged, particularly in industries like petrochemicals and pharmaceuticals. These new materials not only resist corrosion but also improve the overall operational efficiency of pumps, leading to reduced maintenance costs.

As companies continue to invest in these innovative technologies, efficiency and performance in the industrial pump sector are poised for significant improvements, reflecting the industry's commitment to sustainability and operational excellence.

Future Trends in Industrial Pump Innovation and Sustainability

The future of industrial pump innovation is increasingly intertwined with sustainability and efficiency trends. As industries shift towards greener practices, the development of more efficient pumps is essential. The global high-pressure plunger pump market is experiencing a steady growth rate of 3.4% annually. This growth is indicative of a larger trend where companies prioritize both performance and environmental responsibility. The rising demand for sustainable solutions is reshaping product designs, incorporating advanced technologies that reduce energy consumption and enhance operational durability.

In parallel, advancements in intelligent computing capabilities are transforming operational frameworks across sectors. By 2025, China's intelligent computing power is projected to reach an impressive 1037.3 EFLOPS, further enabling the integration of smart technology into industrial processes. This computational capacity will aid in optimizing pump systems, ensuring they meet the demands for efficiency while adhering to sustainability standards. As the market evolves, it is evident that the future of industrial pumps lies not only in their performance but also in their ability to contribute to more sustainable industrial practices.

2025 Top 5 Industrial Pumps: Efficiency and Performance Comparison

Related Posts

-

How to Choose the Right Water Well Pump for Your Home Needs

-

Maximizing Efficiency with Well Pressure Pumps for Sustainable Water Solutions

-

Exploring the Advantages of Flow Jet Water Pumps: A Comprehensive Guide for Homeowners

-

5 Best Artificial Lift Pumps Revolutionizing Oil Recovery: Boost Efficiency and Cut Costs

-

7 Best Ways to Maximize Efficiency with Ultra Jet Pumps

-

The Ultimate Guide to Understanding the Versatility and Efficiency of Flo Jet Pumps in Modern Applications