Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained

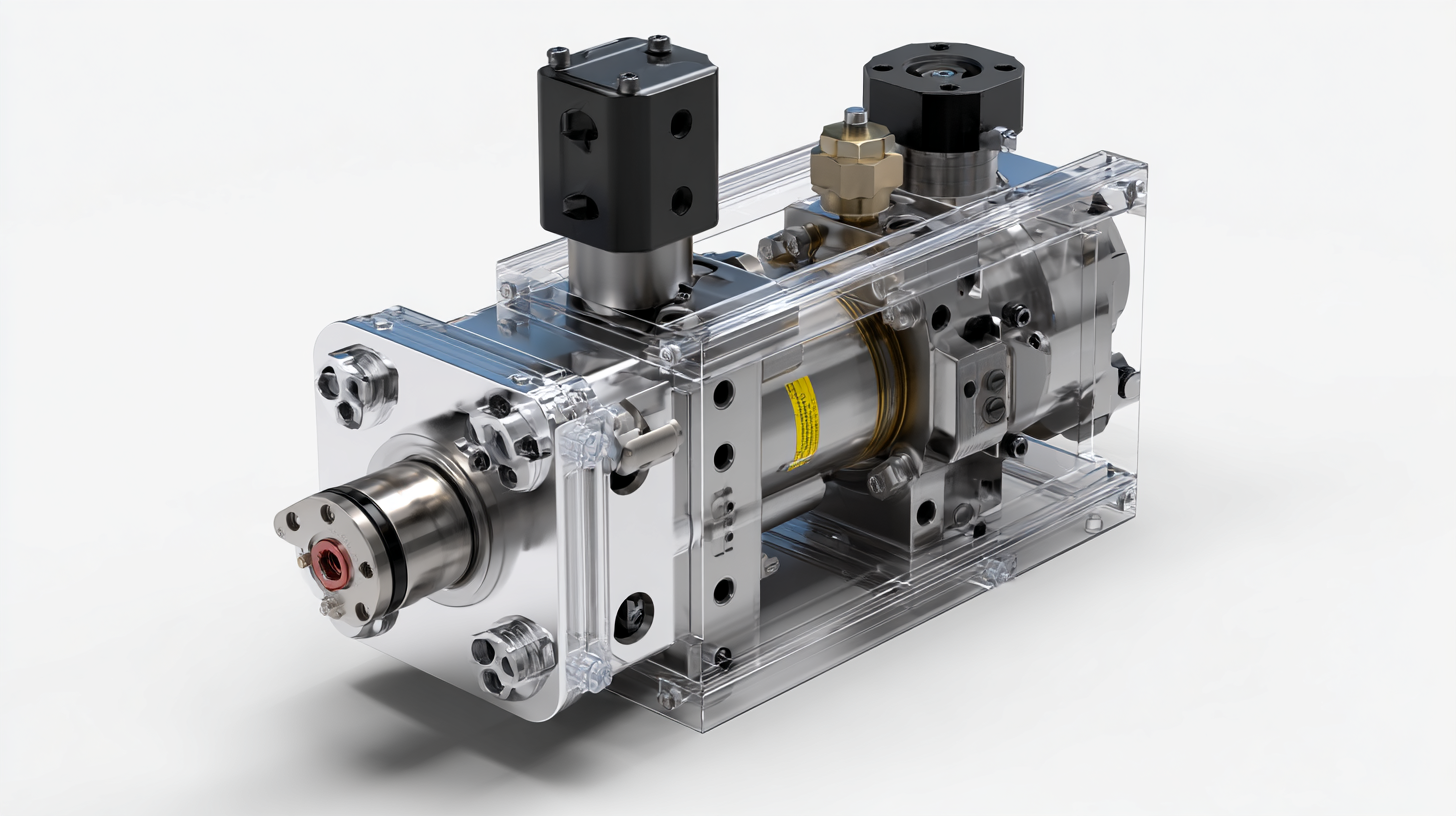

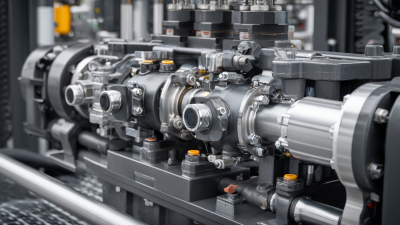

When it comes to powering various machinery and equipment, the choice of components can significantly impact efficiency, performance, and reliability. One essential component that stands out in the realm of hydraulic systems is the hydraulic oil pump. Understanding why one should opt for a hydraulic oil pump is crucial for anyone involved in industrial applications or heavy machinery operations. This article delves into the key benefits and features of hydraulic oil pumps, shedding light on their importance in effectively transferring hydraulic fluid under pressure and powering complex systems.

Hydraulic oil pumps are designed to convert mechanical energy into hydraulic energy, allowing for seamless operation of various functions such as lifting, pushing, and retracting. This capability makes them integral to the functionality of hydraulic systems across multiple industries, from construction to manufacturing. The efficiency of hydraulic oil pumps can lead to improved performance, lower operational costs, and enhanced productivity, making them a preferred choice for businesses looking to optimize their equipment’s capabilities.

As we explore the many advantages and features of hydraulic oil pumps, it becomes evident that their reliability and strength make them a vital investment. Whether you are selecting a pump for a new system or replacing an existing one, understanding these key elements will empower you to make informed decisions that align with your operational needs and ensure long-lasting performance.

Advantages of Hydraulic Oil Pumps for Industrial Applications

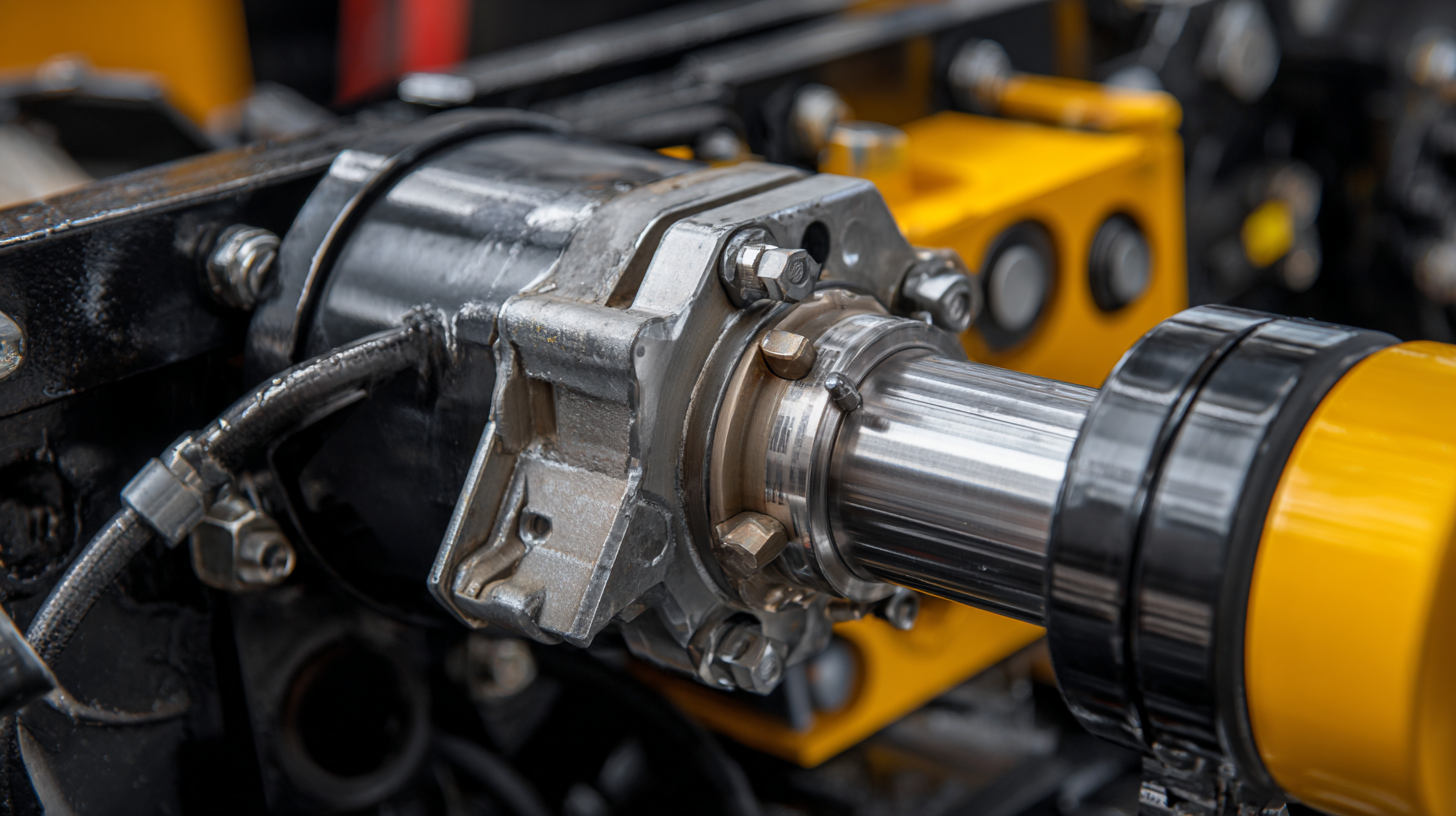

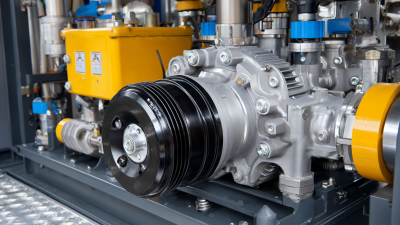

Hydraulic oil pumps play a crucial role in various industrial applications, providing a reliable and efficient means of transferring hydraulic fluids. One of the primary advantages of these pumps is their ability to handle high pressure. According to a report by the International Journal of Engineering Research and Technology, hydraulic systems can operate at pressures exceeding 700 bar, allowing for the effective management of heavy loads and precise control over machine functions. This capability makes hydraulic oil pumps indispensable in sectors such as manufacturing, construction, and transportation.

Another significant benefit of hydraulic oil pumps is their energy efficiency. A study published in the Journal of Fluid Power Systems indicated that hydraulic systems can achieve efficiency rates of up to 90%, significantly reducing energy consumption compared to traditional mechanical systems. Furthermore, hydraulic oil pumps are known for their durability and low maintenance requirements. With proper care, they can last for many years in demanding environments, ensuring a reliable performance while minimizing downtime and operational costs. As industries continue to seek improved efficiency and productivity, hydraulic oil pumps remain a top choice for powering complex machinery and systems.

Why Choose a Hydraulic Oil Pump: Key Benefits and Features Explained - Advantages of Hydraulic Oil Pumps for Industrial Applications

| Feature | Description | Benefits | Application |

|---|---|---|---|

| High Efficiency | Utilizes energy efficiently by minimizing power losses. | Lower operational costs. | Manufacturing, Construction |

| Durability | Built to withstand high pressure and harsh conditions. | Longer lifespan and reduced maintenance. | Mining, Heavy Equipment |

| Versatile Performance | Effective for various fluids and operational demands. | Adaptable to multiple industrial processes. | Logistics, Material Handling |

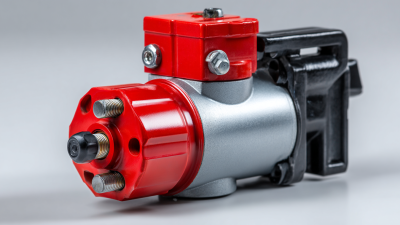

| Compact Design | Space-saving designs fit into confined spaces. | Maximized area usage in facilities. | Automation, Robotics |

| Noise Reduction | Engineered for quieter operation compared to alternatives. | Improved working environment. | Agricultural machinery, Food processing |

Key Features That Enhance Performance and Efficiency

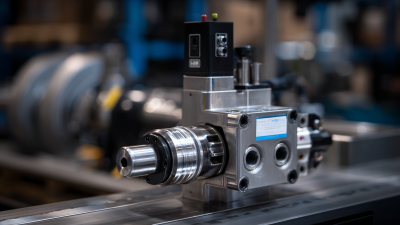

Hydraulic oil pumps are pivotal components in various industrial applications, and their performance is significantly influenced by several key features.

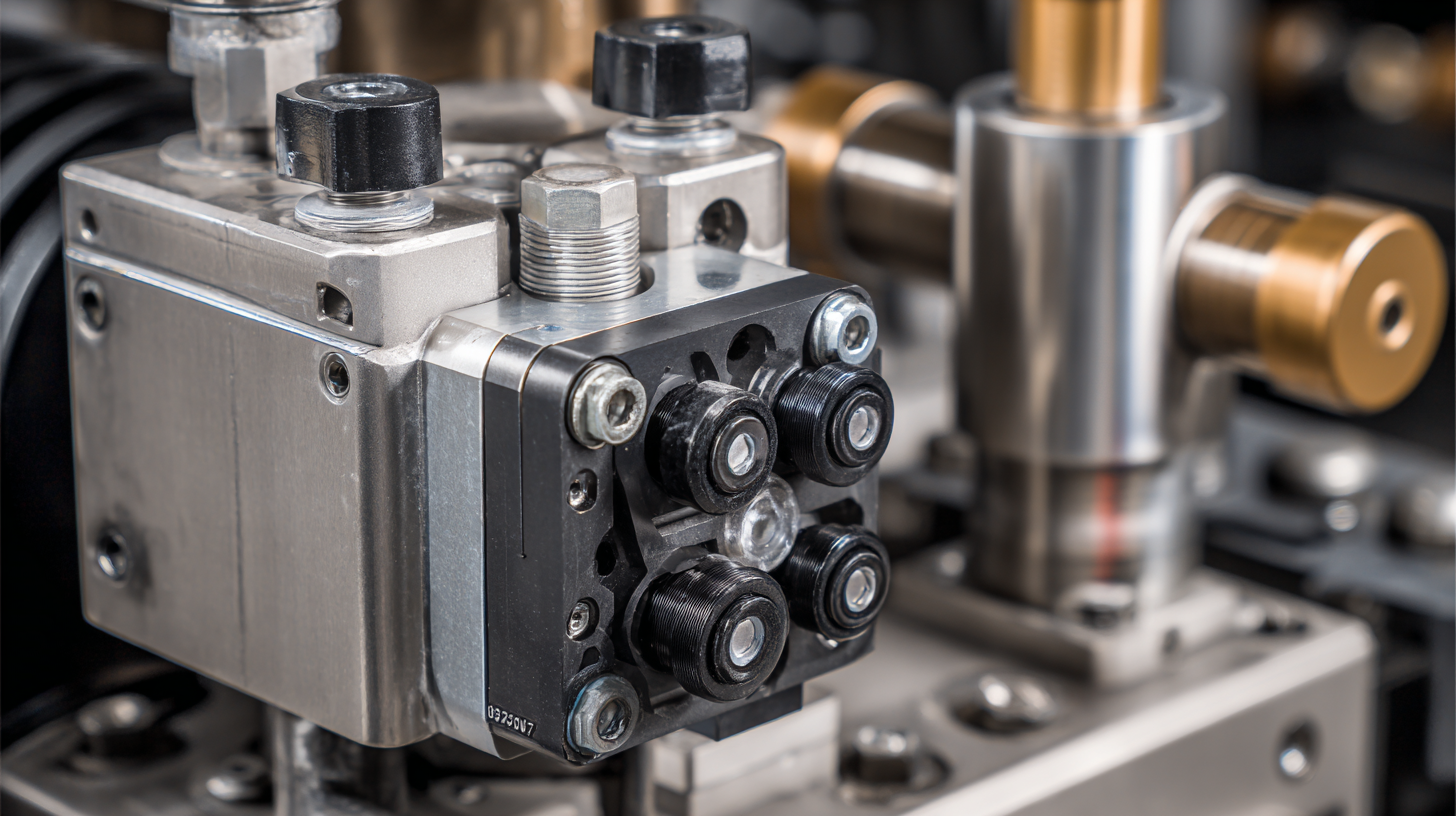

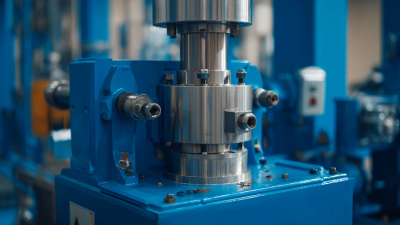

One of the most critical aspects is the pump's displacement design, which determines the amount of hydraulic fluid moved per revolution. High-displacement pumps enhance efficiency by delivering more fluid with less energy consumption, ensuring optimal system performance. Additionally, variable displacement pumps allow for adjustments based on system demand, enabling precise control and energy savings, which are essential in dynamic operational environments.

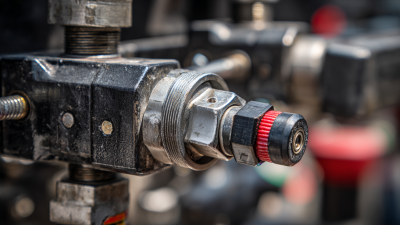

Another important feature is the type of materials used in the construction of hydraulic pumps. Durable materials that resist wear and corrosion extend the pump's lifespan and reduce maintenance costs. Furthermore, advanced sealing technologies protect against fluid leakage and contamination, ensuring reliability and consistent performance in high-pressure situations. Noise reduction features, such as vibration dampening systems, also contribute to improved user experience, making hydraulic oil pumps not only effective but also more compliant with safety and regulatory standards.

All these features combine to enhance the overall efficiency and reliability of hydraulic systems, making the selection of the right hydraulic oil pump crucial for any operation.

Comparative Analysis: Hydraulic Pumps vs. Other Pump Types

When evaluating various pump types, hydraulic pumps stand out due to their ability to generate high pressure and deliver precise control. Compared to centrifugal pumps, which rely on fluid velocity to generate flow, hydraulic pumps are designed to move viscous fluids at consistent speeds. This makes them especially beneficial in applications requiring heavy lifting, such as construction and manufacturing.

Another significant advantage of hydraulic pumps is their efficiency under heavy loads. While diaphragm and gear pumps have their applications, they often cannot match the performance of hydraulic pumps in terms of power transmission in demanding environments. Hydraulic systems can easily accommodate varying flow rates and pressures, providing an unmatched level of flexibility for complex operations. Thus, for industries needing reliable power and sturdy performance, hydraulic pumps emerge as the preferred option.

Understanding Maintenance and Longevity of Hydraulic Oil Pumps

When considering hydraulic oil pumps, understanding their maintenance and longevity is crucial. Regular maintenance can significantly extend the lifespan of these pumps, which are recognized for their efficiency and reliability in various industrial applications. According to a study by the Hydraulic Institute, proper maintenance can increase pump longevity by up to 30%, ultimately reducing operational costs. Key maintenance practices include routine inspections, timely oil changes, and consistent monitoring of temperature and pressure levels.

Tips for maintaining hydraulic oil pumps include regularly checking for leaks, ensuring that the oil is free from contaminants, and lubricating components as recommended by the manufacturer. Additionally, utilizing high-quality hydraulic oil can enhance performance and durability. It is advisable to maintain a meticulous maintenance log to track service intervals and potential issues, allowing for proactive interventions before they lead to major failures.

By investing in diligent maintenance practices, users can capitalize on the benefits of hydraulic oil pumps while maximizing their operational efficiency. Industry research indicates that businesses that prioritize preventive maintenance strategies see a 25% lower incidence of unexpected pump failures, underscoring the importance of taking care of this vital equipment.

Benefits of Hydraulic Oil Pumps

This bar chart illustrates the various key benefits of hydraulic oil pumps, rated on a scale from 1 to 10. The ratings reflect their efficiency, durability, ease of maintenance, cost-effectiveness, and versatility, highlighting why hydraulic oil pumps are a valuable choice for various applications.

Choosing the Right Hydraulic Oil Pump for Your Needs

When selecting a hydraulic oil pump, the first step is to assess your specific needs, including the required flow rate and pressure capacity. Different applications will place varying demands on the pump, so understanding the operational environment is crucial. For instance, industrial machinery often requires a higher flow rate for efficient operation, while mobile machinery may prioritize portability and compact design. Make sure to match the pump’s specifications with the demands of your equipment to ensure optimal performance.

Another important consideration is the type of hydraulic oil the pump will be using. Compatibility with the hydraulic fluid is vital for maintaining efficiency and preventing premature wear. Additionally, look for features such as ease of maintenance, durability, and energy efficiency. Some pumps come with built-in filtration systems or noise reduction capabilities, which can enhance their overall performance. By prioritizing these aspects, you can make an informed choice that aligns with your operational requirements and ensures long-term reliability.

Related Posts

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

20 Best Hydraulic Gas Pumps for Unmatched Performance in 2023

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

-

How to Effectively Maintain Your Hydraulic Gas Pump for Optimal Performance

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

Unlocking Efficiency: How Hydraulic Gas Pumps Revolutionize Industrial Applications