Essential Tips for Choosing the Right Hydraulic Pump?

When selecting a hydraulic pump, the right choice is crucial. A hydraulic pump is a key component in many machines. Its performance directly affects the efficiency of your operation. Understanding the specific requirements of your system can be tricky. There are various types of hydraulic pumps, each with unique features.

Consider the application where the pump will be used. Factors such as pressure, flow rate, and size all matter. For instance, a pump designed for heavy-duty tasks is different from one for lighter applications. Misjudging these parameters can lead to poor performance. Sometimes, what seems ideal on paper may not work in real life.

Evaluate the brand and quality of the hydraulic pump. Cheaper options might seem appealing but can lead to costly repairs. Investing in reliability is often a better strategy. Additionally, maintenance needs and service support should not be overlooked. You’ll need to think about long-term usage. Making an informed choice can avert potential issues and enhance productivity.

Understanding the Basics of Hydraulic Pumps and Their Functions

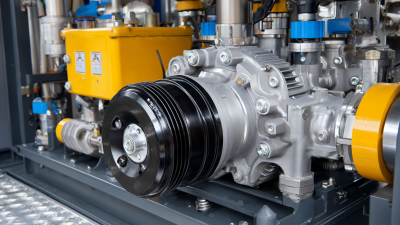

Hydraulic pumps are crucial in converting mechanical energy into hydraulic energy. They create flow by moving hydraulic fluid. This flow generates pressure, enabling various machinery to perform work. Understanding their functions can significantly impact project efficiency and safety.

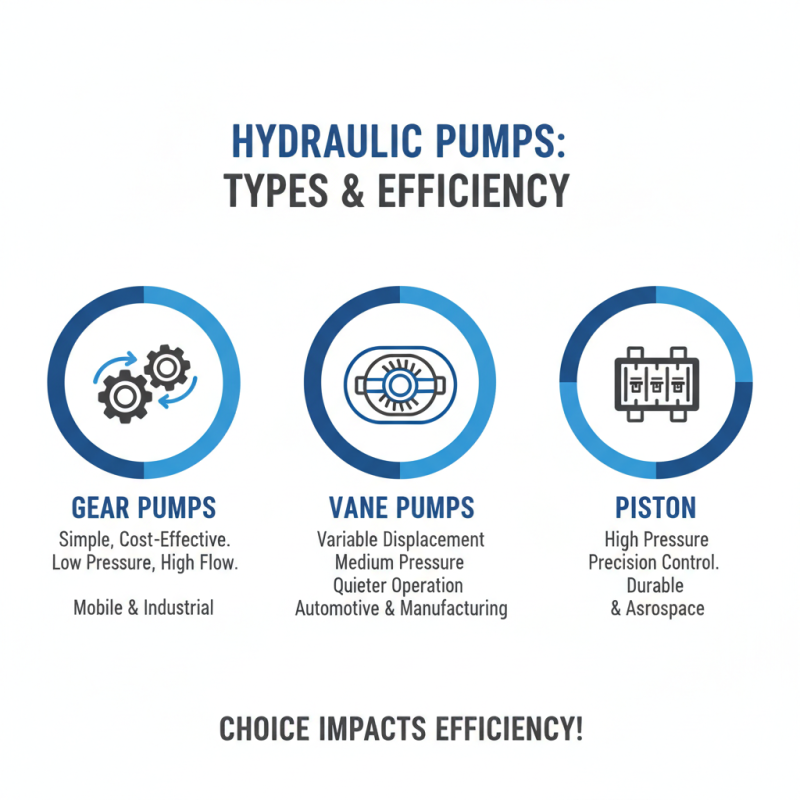

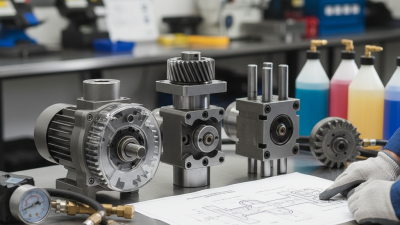

When choosing a hydraulic pump, consider its type and application. There are gear, vane, and piston pumps. Each type has its strengths and weaknesses. For instance, gear pumps are simple and cost-effective but may not perform well under high pressure. Piston pumps, on the other hand, are efficient but can be complex. Knowing the specific requirements, such as pressure and flow rates, is vital to make an informed decision.

Additionally, maintenance is an aspect often overlooked. Regular checks can prevent breakdowns. Neglecting this can lead to costly repairs and downtime. It's essential to consider the environment too. Factors like temperature and presence of contaminants can affect performance. Assessing these details helps ensure longevity and reliability in your hydraulic system.

Essential Tips for Choosing the Right Hydraulic Pump

Key Factors to Consider When Selecting a Hydraulic Pump

Choosing the right hydraulic pump is crucial for efficiency. Numerous factors play a role in making this choice. One key aspect is the pump type. Gear, piston, and vane pumps each have distinct applications. Understanding their differences is vital. For example, gear pumps are often used in low-pressure scenarios. They are simple but may lack efficiency in high-demand tasks.

Next, consider the required flow rate. This indicates how much fluid needs to be moved. Assessing the flow requirements prevents underperformance. An inadequate flow rate can result in equipment strain. It’s important to calculate the necessary flow accurately for optimal performance. Many overlook this detail, leading to operational issues.

Another vital factor is pressure rating. Hydraulic systems require pumps that can handle specific pressure levels. Exceeding these ratings can cause failures. Regular assessments are necessary to ensure compliance. Finally, consider system compatibility. Pumps must align with your hydraulic system specifications. Mismatches can result in inefficiency or even damage. Proper evaluation of these elements can lead to better choices overall. However, balancing these factors can be challenging.

Types of Hydraulic Pumps and Their Applications

Hydraulic pumps are essential in various industrial applications. Understanding the types of hydraulic pumps can greatly impact efficiency. The most common types include gear, vane, and piston pumps. Each type has unique advantages and specific uses.

Gear pumps are reliable and compact. They work well for low-pressure applications. However, they may not be suitable for high-viscosity fluids. Industry reports suggest that gear pumps account for nearly 30% of the market share. Vane pumps, known for their flexibility, are commonly used in construction equipment. Still, they can suffer from wear over time.

Piston pumps offer high pressure and efficiency. They are ideal for heavy machinery and aerospace. Yet, they can be more complex, leading to higher maintenance costs. Data shows that piston pumps represent about 45% of hydraulic pump usage in demanding operations. Each pump type has its strengths and weaknesses. Understanding these details helps in making informed decisions for specific applications. Selecting the wrong type can lead to efficiency losses and increased operational costs.

Evaluating Hydraulic Pump Specifications and Performance Metrics

When selecting a hydraulic pump, evaluating specifications is crucial. Pay attention to flow rate, pressure, and efficiency. The flow rate indicates the amount of fluid moved, impacting overall system performance. Higher flow often leads to improved speed for hydraulic cylinders.

Pressure ratings are equally important. They determine how much force the pump can generate. A pump with low pressure may struggle in demanding applications. Efficiency ratings tell you how well the pump converts input power into hydraulic power. Look for detailed efficiency metrics in the specifications.

It's essential to also consider the application. Different tasks may require varying types of pumps. Evaluate how the pump fits your specific needs. This should include the environment in which the pump operates. Outdoor conditions can affect durability and performance. Reflection on these factors may reveal potential oversights in your selection process.

Essential Tips for Choosing the Right Hydraulic Pump

| Specification | Metric | Standard Value | Recommended Range | Performance Impact |

|---|---|---|---|---|

| Flow Rate (GPM) | Gallons Per Minute | 20 | 15 - 30 | Affects speed of operation |

| Pressure Rating (PSI) | Pounds per Square Inch | 3000 | 2000 - 3500 | Determines load capacity |

| Motor Power (HP) | Horsepower | 5 | 3 - 10 | Impacts energy consumption |

| Efficiency (%) | Percentage | 90 | 80 - 95 | Reduces operational costs |

| Weight (lbs) | Pounds | 150 | 100 - 200 | Affects installation and mobility |

Maintenance Tips for Choosing a Durable Hydraulic Pump

When selecting a hydraulic pump, durability is key to long-term performance. Regular maintenance can ensure the pump runs smoothly and efficiently. First, consider the operating environment. Dust, debris, and exposure to moisture can affect the pump's lifespan. Installing filters may help.

Monitor fluid levels regularly. Low fluid can lead to pump wear. Replace the oil according to the manufacturer’s recommendations. Sometimes, people forget. It's crucial to check seals and connections for leaks during regular inspections. Minor leaks can escalate into major issues.

Another important tip is to listen to your pump. Strange noises could indicate problems. If you notice vibrations, it might need attention. Don't wait until it fails. Analyzing these signs early can prevent costly downtime. Keep a log of maintenance activities. This practice helps identify patterns. It’s a simple step that can lead to better decisions in the future.

Related Posts

-

How to Select the Right Hydraulic Pump for Your Project Needs

-

What is the Functionality of a Hydraulic Fluid Pump in Modern Machinery

-

Innovative Trends in Hydraulic Gas Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Importance of Hydraulic Pumps in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Hydraulic Oil Pump for Your Needs

-

How to Choose the Right Hydraulic Oil Pump for Your Needs?